Patents

Literature

33results about How to "Unique fiber cavity structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coarse-aggregate-containing C240-strength-grade ultrahigh-performance fiber concrete and preparation method

ActiveCN107285708AImprove toughnessImprove deformation abilitySolid waste managementModified carbonCellulose fiber

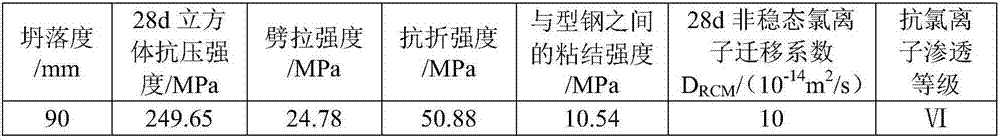

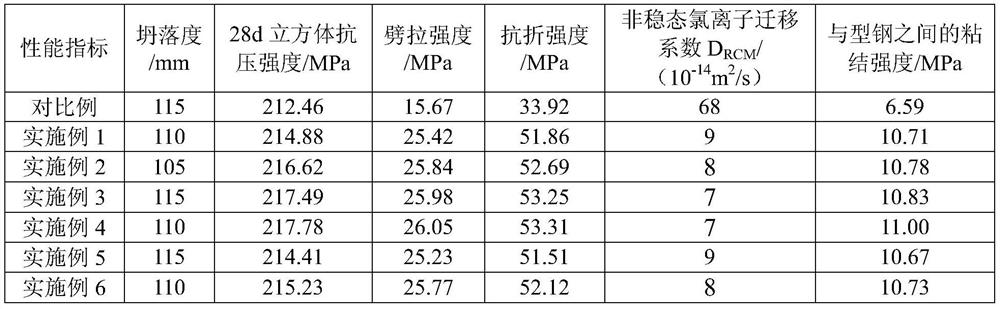

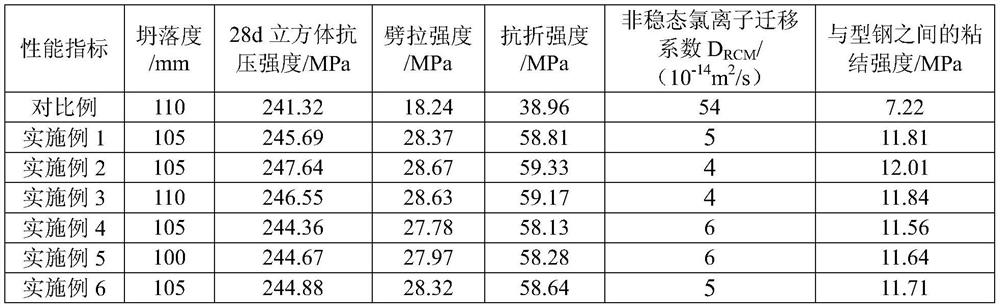

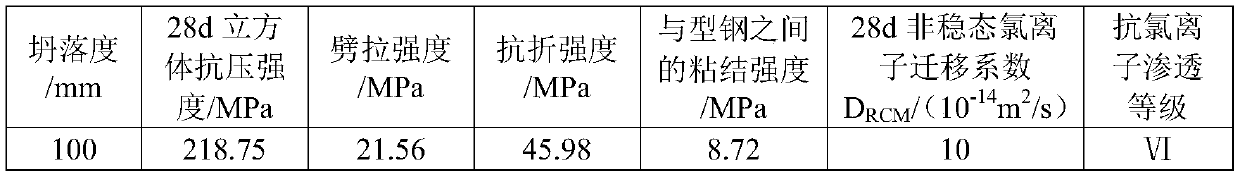

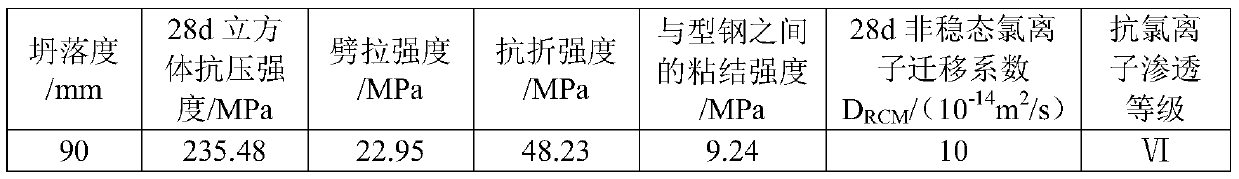

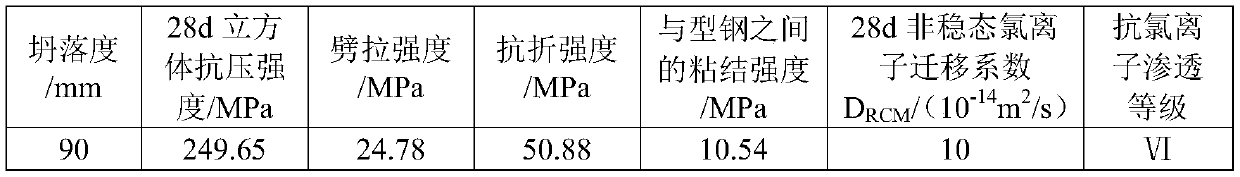

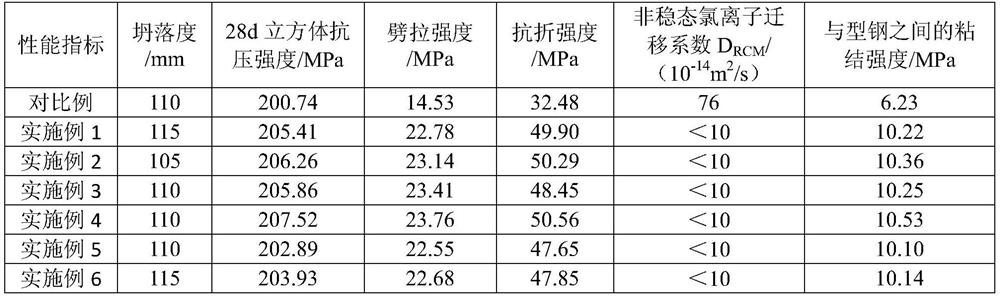

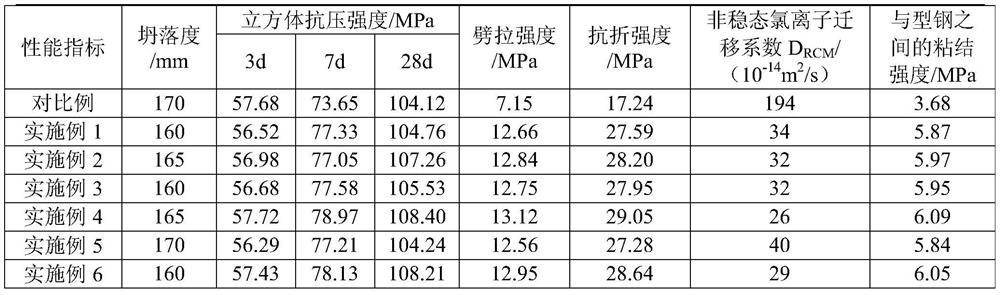

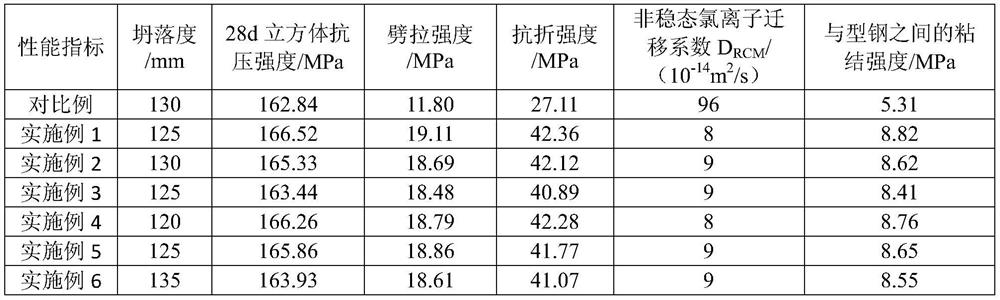

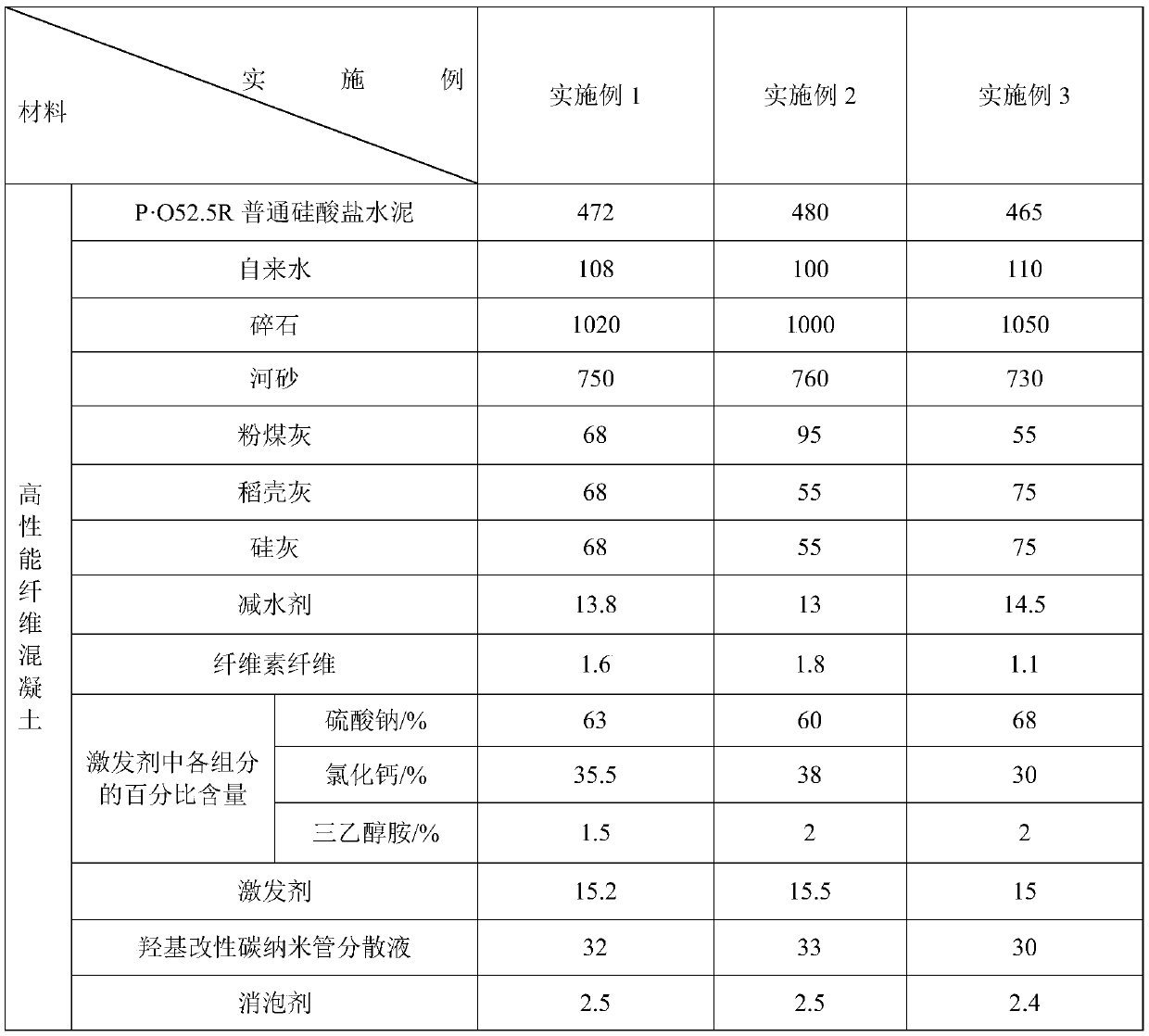

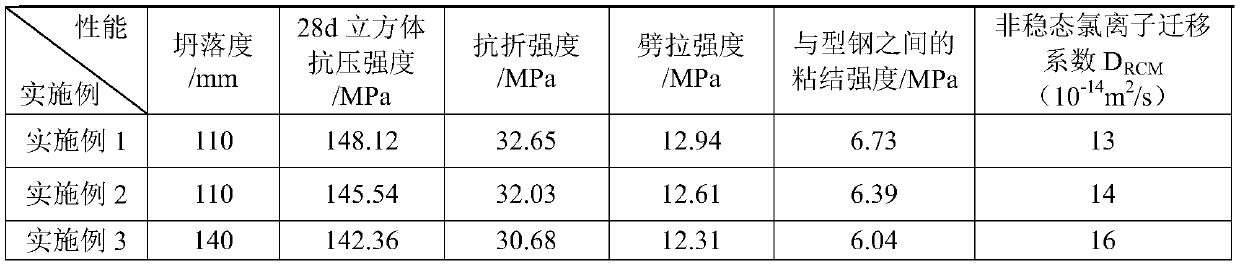

The invention discloses coarse-aggregate-containing C240-strength-grade ultrahigh-performance fiber concrete and a preparation method. The concrete is composed of, by mass, 578 parts of cement, 62 parts of water, 880 parts of rubble, 800 parts of fine aggregate, 70 parts of coal ash, 60 parts of rice husk ash, 154 parts of silicon ash, 16.5 parts of water reducer, 11.5 parts of excitant, 1.7 parts of cellulosic fiber, 90 parts of steel fiber, 51 parts of hydroxyl modified carbon nanotube dispersion, 54 parts of oxidized graphene dispersion and 2.9 parts of defoamer. The concrete prepared by the method has high toughness and durability and has high binding strength with section steel, compressive strength reaches 249.65MPa, bending strength reaches 50.88MPa, splitting tensile strength reaches 24.78MPa, the binding strength with the section steel reaches 10.54MPa, and chlorion anti-permeation grade reaches VI grade. When the concrete is used in a section steel and concrete combined structure, cooperative working performance between the section steel and the concrete can be brought into play effectively, and the defects that the section steel and the concrete are poor in binding performance and respective mechanical performance of the section steel and the concrete cannot be brought into full play are made up.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

High-toughness and high-cohesiveness C250 ultrahigh-strength hybrid fiber concrete and preparation method thereof

ActiveCN113024189AHigh tensile strengthHigh elastic modulusSolid waste managementPolymer sciencePolyvinyl alcohol

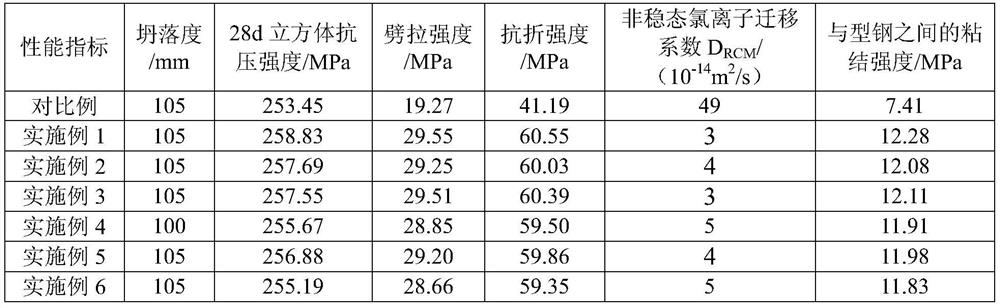

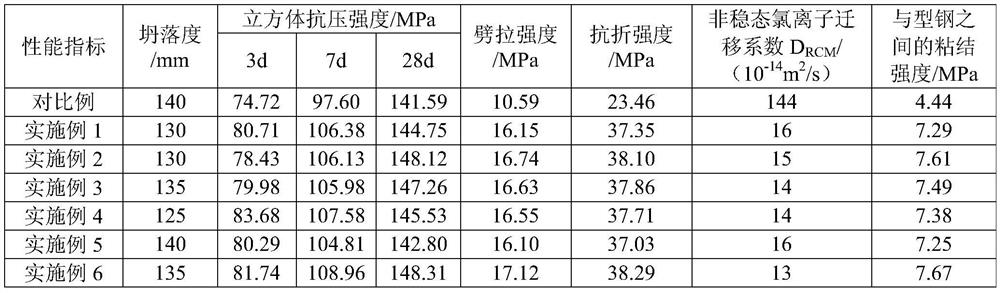

The invention discloses high-toughness and high-cohesiveness C250 ultrahigh-strength hybrid fiber concrete and a preparation method thereof. The ultrahigh-strength hybrid fiber concrete is prepared from cement, sand, gravel, fly ash, straw ash, silica fume, nano silicon, water, a water reducing agent, an exciting agent, a defoaming agent, a shrinkage reducing agent, ramie fibers, basalt fibers, CaCO3 whiskers, a carboxyl modified polyvinyl alcohol polymer and nano titanium / graphene oxide dispersion liquid according to the mixing ratio of (550-560): (760-770): (830-840): (65-70): (103- 108): (125-135): (5.4-5.6): (70-75): (20-21): (16-17): (3-3.3): (14.5-15): (7.5-8): (13.3-13.6): (21-21.5): (22-23.5): (42-46). The materials are evenly mixed at intervals through a layered stirring method, and discharging, forming and curing are conducted. The mechanical property and durability of the concrete and the bonding property between the concrete and the profile steel are obviously improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

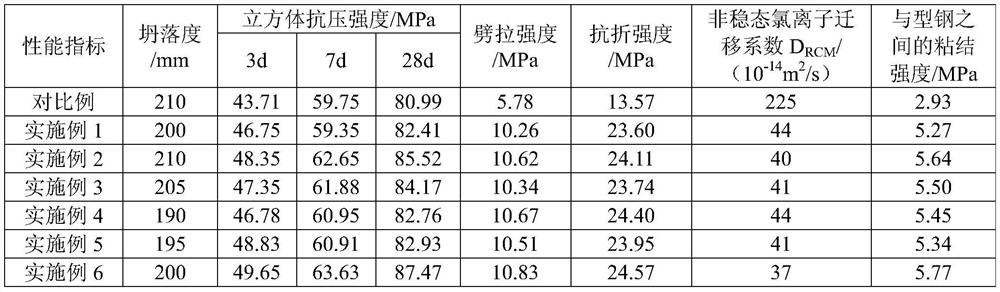

High-toughness and high-cohesiveness C130-strength high-strength fiber concrete and preparation method thereof

ActiveCN113024213AImprove adhesionImprove flexural strengthSolid waste managementCement mixing apparatusPolymer sciencePolyvinyl alcohol

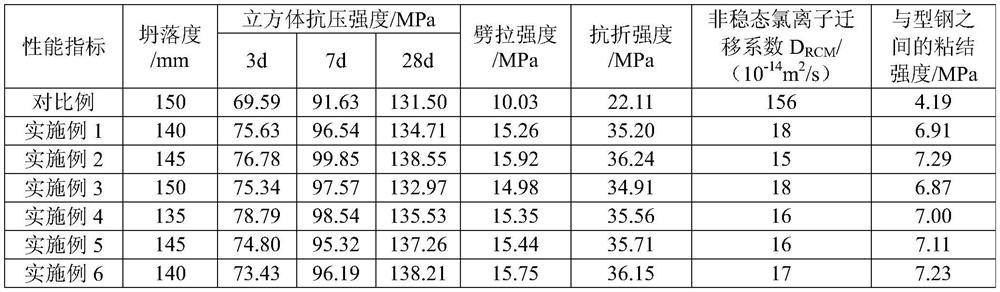

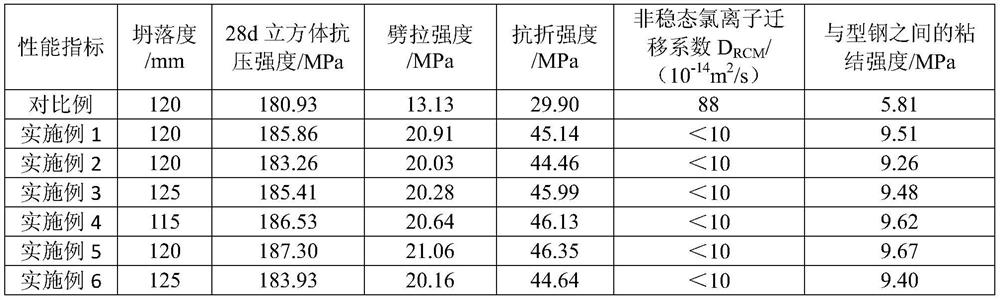

The invention discloses high-toughness and high-cohesiveness C130-strength high-strength fiber concrete and a preparation method thereof. The concrete is prepared from cement, sand, gravel, fly ash, straw ash, silica fume, nano silicon, water, a water reducing agent, an exciting agent, a defoaming agent, a shrinkage reducing agent, ramie fibers, basalt fibers, CaCO3 whiskers and a carboxyl modified polyvinyl alcohol polymer according to the mixing ratio of (425-430): 718: 985: (80-85): (60-65): (30-35): (3.5-4.2): (120- 125): (12-13): (13-14): (1.9-2.3): (10-11): (5.4-5.6): (9-9.4): (17.8- 18.1): (20-22). The materials are evenly mixed at intervals through a layered stirring method, and discharging, forming and curing are conducted. The fracture resistance, the compression resistance, the bonding strength with the profile steel and the impermeability of the concrete are remarkably enhanced, and the cooperative work capacity with the profile steel is further improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

High-toughness and high-cohesiveness C150-strength ultrahigh-strength fiber concrete and preparation method thereof

PendingCN113024211AImprove adhesionImprove flexural strengthSolid waste managementCement mixing apparatusPolymer sciencePolyvinyl alcohol

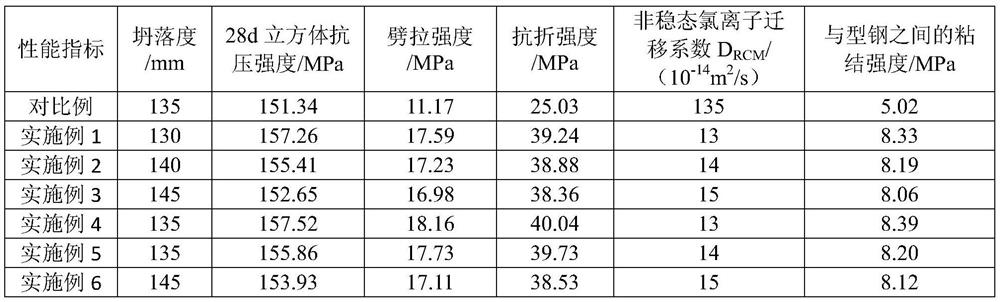

The invention discloses high-toughness and high-cohesiveness C150-strength ultrahigh-strength fiber concrete and a preparation method thereof. The ultrahigh-strength fiber concrete is prepared from cement, sand, gravel, fly ash, straw ash, silica fume, nano silicon, water, a water reducing agent, an exciting agent, a defoaming agent, a shrinkage reducing agent, ramie fibers, basalt fibers, hydroxyl modified single-walled carbon nanotube dispersion liquid and a carboxyl modified polyvinyl alcohol polymer according to the mixing ratio of (460-470): (710-720): 985: (75-85): (65-70): (40-45): (3.8-4.4): (105-110): (14-16): (12-13): (2.2-2.6): (11-12): (5.5-5.7): (9.8-10.2): (25-30): (16.5-18). The materials are evenly mixed at intervals through a layered stirring method, and discharging, forming and curing are conducted. The concrete mechanics including the profile steel bonding performance and the durability are remarkably improved, and the cooperative work capacity with the profile steel is enhanced.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

High-toughness and high-cohesiveness C80-strength fiber concrete and preparation method thereof

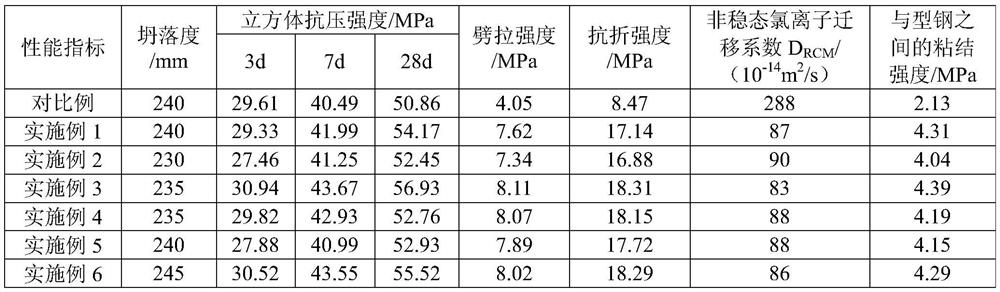

The invention discloses high-toughness and high-cohesiveness C80-strength fiber concrete and a preparation method thereof. The concrete is prepared from cement, river sand, broken stone, fly ash, straw ash, silica fume, nano silicon, water, a water reducing agent, an exciting agent, a defoaming agent, a shrinkage reducing agent, ramie fibers, basalt fibers and CaCO3 crystal whiskers according to the mixing ratio of (360-370): 725: 1007: (100-110): (55-65): (17-19): (2.5-4): (150-155): (8.5-9.5): (12.5-13.5): (1.8-2.1): (7.8-8.2): (4.9-5.2): (8.1-8.3): (17.4-17.6). Through a layered stirring method, all the materials are uniformly mixed at intervals, and discharging, forming and curing are performed. The compression resistance, the fracture resistance, the splitting tensile strength, the toughness, the durability and the like of the concrete can be effectively improved, and the bonding strength and the cooperative deformation capacity between the concrete and the profile steel are enhanced.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

High-toughness high-cohesiveness C70 strength fiber concrete and preparation method thereof

PendingCN113185212AHigh tensile strengthHigh elastic modulusCeramic shaping apparatusCement mixing apparatusBasalt fiberUltimate tensile strength

The invention discloses high-toughness and high-cohesiveness C70 strength fiber concrete and a preparation method thereof. The concrete is prepared from cement, river sand, broken stone, fly ash, straw ash, silica fume, nano silicon, water, a water reducing agent, an exciting agent, a defoaming agent, a shrinkage reducing agent, ramie fiber, basalt fiber and CaCO3 whisker according to the mixing ratios of (350 to 360): (723): (1010): (105 to 112): (45 to 55): (14 to 17): (2 to 3.5): (155 to 160): (7.5 to 8.5): (12 to 13): (1.8 to 2.1): (6.8 to 7.8): (4.7 to 4.9): (7.9 to 8.1): (17.3 to 17.5). Through a layered stirring method, all the materials are uniformly mixed at intervals, and discharging, forming and curing are performed. The compression resistance, the fracture resistance, the splitting tensile strength, the toughness, the durability and the like of the concrete can be effectively improved, and the bonding strength and the cooperative deformation capacity between the concrete and profile steel are enhanced.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

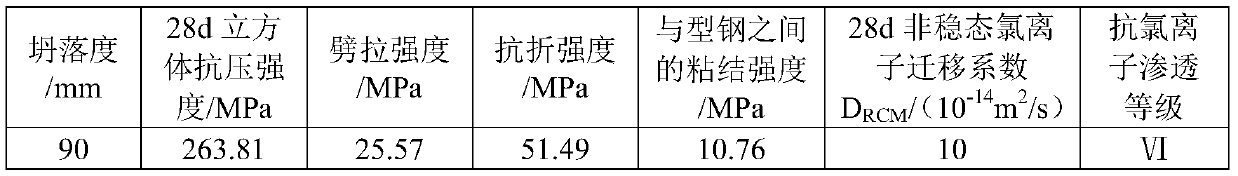

A kind of C250 strength grade ultra-high performance fiber concrete containing coarse aggregate and its preparation method

ActiveCN107285711BImprove toughnessImprove deformation abilitySolid waste managementAggregate (composite)Modified carbon

The invention discloses a C250 strength grade ultra-high performance fiber concrete containing coarse aggregate and a preparation method thereof. The mass parts of the concrete are as follows: 596 parts of cement, 60 parts of water, 870 parts of gravel, and 810 parts of fine aggregate 70 parts of fly ash, 65 parts of rice husk ash, 168 parts of silica fume, 17 parts of water reducer, 12 parts of activator, 1.6 parts of cellulose fiber, 85 parts of steel fiber, 55 parts of hydroxyl modified carbon nanotube dispersion Parts, 58 parts of graphene oxide dispersion liquid, 3.0 parts of defoamer. The prepared concrete has high toughness and durability, and has a high bond strength with the steel, with a compressive strength of 263.81MPa, a flexural strength of 51.49MPa, and a splitting tensile strength of 25.57MPa. The bonding strength reaches 10.76MPa, and the chloride ion impermeability level reaches level VI. Used in steel-concrete composite structures, it can effectively exert the synergistic performance between steel and concrete, make up for the poor bonding performance of steel and concrete, and the inability to give full play to their respective mechanical properties.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

High-toughness and high-cohesiveness C60 strength fiber concrete and preparation method thereof

The invention discloses high-toughness and high-cohesiveness C60 strength fiber concrete and a preparation method thereof. The concrete is prepared from cement, river sand, broken stone, fly ash, straw ash, silica fume, nano silicon, water, a water reducing agent, an exciting agent, a defoaming agent, a shrinkage reducing agent, ramie fibers, basalt fibers and CaCO3 whiskers according to the mixing ratio of (340-350): 719: 1015: (108-115): (40-50): (13-16): (1.5-3): (160-165): (6.5-7.5): (11.5-12.5): (1.6-2): (5.8-6.8): (4.5-4.7): (7.8-8): (17.1-17.4). Through a layered stirring method, all the materials are uniformly mixed at intervals, and discharging, forming and curing are performed. The compression resistance, the fracture resistance, the splitting tensile strength, the toughness, the durability and the like of the concrete can be effectively improved, and the bonding strength and the cooperative deformation capacity between the concrete and the profile steel are enhanced.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

High-toughness and high-cohesiveness C210 ultrahigh-strength hybrid fiber concrete and preparation method thereof

ActiveCN113024142AImprove adhesionImprove flexural strengthSolid waste managementCement mixing apparatusPolymer sciencePolyvinyl alcohol

The invention discloses high-toughness and high-cohesiveness C210 ultrahigh-strength hybrid fiber concrete and a preparation method thereof. The ultrahigh-strength hybrid fiber concrete is prepared from cement, sand, gravel, fly ash, straw ash, silica fume, nano silicon, water, a water reducing agent, an exciting agent, a defoaming agent, a shrinkage reducing agent, ramie fibers, basalt fibers, CaCO3 whiskers, a carboxyl modified polyvinyl alcohol polymer andnanometer titanium / graphene oxide dispersion liquid according to the mixing ratio of (525-535):(735-740):(890-900): (70-80): (85-95:(95-100):(4.7-5):(90-95):(17-18):(14.5-15):(2.5-2.9) :(12-13):(6.5-6.7):(12.2-12.5):(19-19.3):(20.5-22):(33-36). The materials are uniformly mixed by a layered stirring method, and are prepared and maintained. The mechanical property of the concrete and the bonding property and durability between the concrete and the profile steel are obviously improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

High-toughness and high-cohesiveness C180 ultrahigh-strength fiber concrete and preparation method thereof

ActiveCN113233832AImprove adhesionImprove flexural strengthSolid waste managementPolymer sciencePolyvinyl alcohol

The invention discloses high-toughness and high-cohesiveness C180 ultrahigh-strength fiber concrete and a preparation method thereof. The high-toughness and high-cohesiveness C180 ultrahigh-strength fiber concrete is prepared from cement, sand, gravel, fly ash, straw ash, silica fume, nano silicon, water, a water reducing agent, an exciting agent, a defoaming agent, a shrinkage reducing agent, ramie fibers, basalt fibers, hydroxyl modified single-walled carbon nanotube dispersion liquid and a carboxyl modified polyvinyl alcohol polymer according to the mixing ratio of (490-496): (710-725): 970: (68-72): (75-77): (60-67): (4.3-4.5): (92-97): (16-17): (13.5-14): (2.4-2.8): (13.5-14.5): (5.9-6.2): (10.7-11): (29.5-32): (19-21). The materials are evenly mixed at intervals through a layered stirring method, and discharging, forming and curing are conducted. The mechanical property of the concrete and the bonding property and durability of the concrete and the profile steel are remarkably improved, and the cooperative working capacity of the concrete and the profile steel is enhanced.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

High-toughness and high-cohesiveness C50-strength fiber concrete and preparation method thereof

PendingCN113024187AInhibition formationHigh strengthSolid waste managementBasalt fiberUltimate tensile strength

The invention discloses high-toughness and high-cohesiveness C50-strength fiber concrete and a preparation method thereof. The concrete is prepared from cement, river sand, broken stone, fly ash, straw ash, silica fume, nano silicon, water, a water reducing agent, an exciting agent, a defoaming agent, a shrinkage reducing agent, ramie fibers, basalt fibers and CaCO3 whiskers according to the mixing ratio of (330-340): 715: 1020: (110-125): (30-40): (10-14): (1-3): (170-180): (5.5-6.5): (11-12): (1.5-1.8): (5.5-6): (4.5-4.6): (7.8-7.9): (17-17.3). Through a layered stirring method, all the materials are uniformly mixed at intervals, and discharging, forming and curing are performed. The compression resistance, the fracture resistance, the splitting tensile strength, the toughness, the durability and the like of the concrete can be effectively improved, and the bonding strength and the cooperative deformation capacity between the concrete and the profile steel are enhanced.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

High-toughness and high-cohesiveness C240 ultrahigh-strength hybrid fiber concrete and preparation method thereof

PendingCN113024184AWell gradedImprove adhesionSolid waste managementCeramic shaping apparatusSilica fumeDefoaming Agents

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

A kind of ultra-high performance fiber concrete of c210 strength grade containing coarse aggregate and its preparation method

ActiveCN107352916BImprove toughnessImprove deformation abilitySolid waste managementAggregate (composite)Modified carbon

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

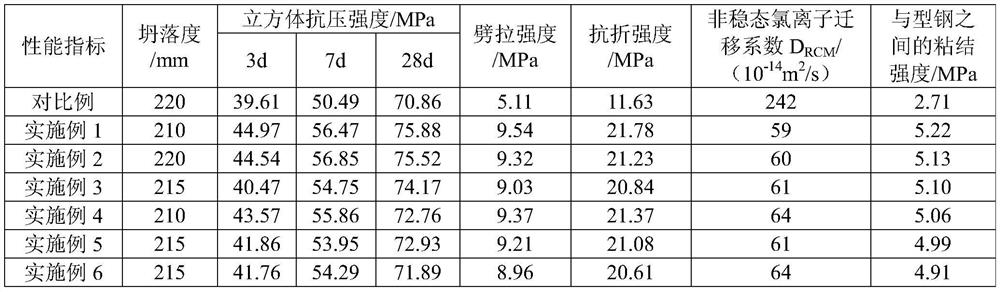

High-strength fiber concrete with high toughness and high cohesion c110 strength and its preparation method

ActiveCN113024183BHigh tensile strengthHigh elastic modulusSolid waste managementCement mixing apparatusPolyvinyl alcoholCrushed stone

The invention discloses a high-strength fiber concrete with high toughness and high cohesiveness C110 strength and a preparation method thereof. The mixing ratio includes: cement: sand: crushed stone: fly ash: straw ash: silica fume: nano-silicon: water: water-reducing Agent: activator: defoamer: shrinkage reducer: ramie fiber: basalt fiber: CaCO 3 Whiskers: carboxyl-modified polyvinyl alcohol polymer = 405‑415: 713: 995: 85‑90: 45‑55: 20‑25: 3‑4: 125‑130: 11‑12: 12‑13: 1.8‑ 2.1: 9‑9.5: 5.2‑5.4: 8.7‑8.9: 17.6‑17.8: 18‑20. The material is mixed evenly at intervals by the layered stirring method, and the material is discharged, formed and maintained. The bending resistance, compression resistance, bonding strength and impermeability of the concrete in the invention are significantly enhanced, and the cooperative work ability with the steel is further improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

High-toughness and high-cohesiveness C110-strength high-strength fiber concrete and preparation method thereof

ActiveCN113024183AImprove adhesionImprove flexural strengthSolid waste managementCement mixing apparatusPolymer sciencePolyvinyl alcohol

The invention discloses high-toughness and high-cohesiveness C110-strength high-strength fiber concrete and a preparation method thereof. The concrete comprises the following components: cement, sand, broken stone, fly ash, straw ash, silica fume, nano silicon, water, a water reducing agent, an exciting agent, a defoaming agent, a shrinkage reducing agent, ramie fibers, basalt fibers, CaCO3 whiskers and a carboxyl modified polyvinyl alcohol polymer in a mixing ratio of (405-415): 713: 995: (85-90): (45-55): (20-25): (3-4): (125-130): (11-12): (12-13): (1.8-2.1): (9-9.5): (5.2-5.4): (8.7-8.9): (17.6-17.8): (18-20). The materials are evenly mixed at intervals through a layered stirring method, and discharging, forming and curing are conducted. The fracture resistance, the compression resistance, the bonding strength with the profile steel and the impermeability of the concrete are all remarkably enhanced, and the cooperative work capacity with the profile steel is further improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

High-toughness and high-cohesiveness C90-strength fiber concrete and preparation method thereof

The invention discloses high-toughness and high-cohesiveness C90 strength fiber concrete and a preparation method thereof. The concrete is prepared from cement, river sand, broken stone, fly ash, straw ash, silica fume, nano silicon, water, a water reducing agent, an exciting agent, a defoaming agent, a shrinkage reducing agent, ramie fibers, basalt fibers and CaCO3 crystal whiskers according to the mixing ratio of (370-380): 728: 1004: (90-100): (65-75): (19-22): (2.8-4): (140-150): (10-11.5): (13-14): (2-2.3): (8.2-8.8): (5-5.2): (8.2-8.4): (17.5-17.7). Through a layered stirring method, all the materials are uniformly mixed at intervals, and discharging, forming and curing are performed. The compression resistance, the fracture resistance, the splitting tensile strength, the toughness, the durability and the like of the concrete can be effectively improved, and the bonding strength and the cooperative deformation capacity between the concrete and the profile steel are enhanced.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

A kind of C230 strength grade ultra-high performance fiber concrete containing coarse aggregate and its preparation method

ActiveCN107512887BImprove toughnessImprove deformation abilitySolid waste managementAggregate (composite)Modified carbon

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

High-toughness and high-cohesiveness C120-strength high-strength fiber concrete and preparation method thereof

PendingCN113185211AImprove adhesionImprove flexural strengthSolid waste managementPolyvinyl alcoholBasalt fiber

The invention discloses high-toughness and high-cohesiveness C120-strength high-strength fiber concrete and a preparation method thereof. The concrete is prepared from cement, sand, gravel, fly ash, straw ash, silica fume, nano silicon, water, a water reducing agent, an exciting agent, a defoaming agent, a shrinkage reducing agent, ramie fiber, basalt fiber, CaCO3 whisker and carboxyl modified polyvinyl alcohol polymer according to mixing ratios of (415 to 425) to (715 to 999) to (85 to 90) to (55 to 65) to (25 to 30) to (3.2 to 4.2) to (125 to 130) to (11 to 12.5) to (13 to 13.5) to (1.9 to 2.2) to (9 to 10) to (5.3 to 5.5) to (8.9 to 9.1) to (17.7 to 18) to (19 to 21). The materials are evenly mixed at intervals through a layered stirring method, and discharging, forming and curing are conducted. The mechanical property of the concrete and the adhesive property and anti-permeability between the concrete and profile steel are all remarkably enhanced, and the cooperative work capacity of the concrete and the profile steel is improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

High-toughness and high-cohesiveness C170-strength ultrahigh-strength fiber concrete and preparation method thereof

ActiveCN113024191AImprove adhesionImprove flexural strengthSolid waste managementPolymer sciencePolyvinyl alcohol

The invention discloses high-toughness and high-cohesiveness C170-strength ultrahigh-strength fiber concrete and a preparation method thereof. The concrete is prepared from cement, sand, gravel, fly ash, straw ash, silica fume, nano silicon, water, a water reducing agent, an exciting agent, a defoaming agent, a shrinkage reducing agent, ramie fibers, basalt fibers, hydroxyl modified single-walled carbon nanotube dispersion liquid and a carboxyl modified polyvinyl alcohol polymer according to the mixing ratio of (480-490): (715-725): 975: (70-75): (70-75): (55-60): (4.2-4.4): (95-100): (15-17): (13.5-14): (2.4-2.8): (13-14): (5.7-6): (10.4-10.7): (28-32): (18-20). The materials are evenly mixed at intervals through a layered stirring method, and discharging, forming and curing are conducted. The concrete mechanics including the structural steel bonding performance and the durability are remarkably improved, and the cooperative work capacity of the concrete and the structural steel is enhanced.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

A kind of ultra-high performance fiber concrete of C220 strength grade containing coarse aggregate and its preparation method

ActiveCN107285707BImprove toughnessImprove deformation abilitySolid waste managementAggregate (composite)Modified carbon

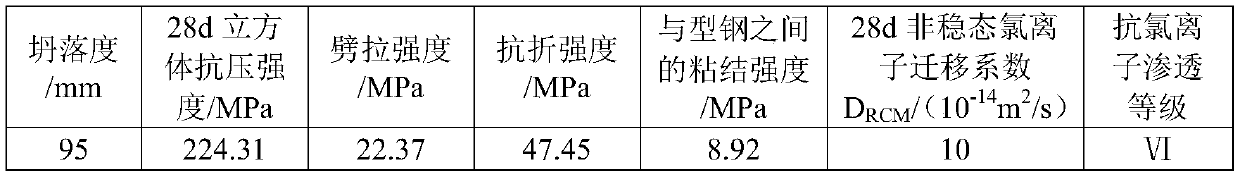

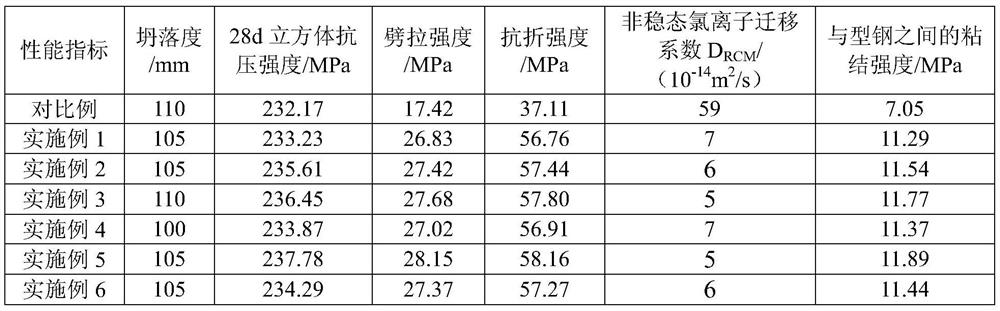

The invention discloses a C220 ultra-high-performance fiber concrete containing coarse aggregate and a preparation method thereof. The mass parts of the concrete are as follows: 545 parts of cement, 63 parts of water, 900 parts of crushed stone, fine aggregate 750 parts, 72 parts of fly ash, 65 parts of rice husk ash, 140 parts of silica fume, 15.5 parts of water reducing agent, 11.5 parts of activator, 1.7 parts of cellulose fiber, 78 parts of steel fiber, hydroxyl modified carbon nanotube dispersion 48 parts, 50 parts of graphene oxide dispersion, 2.9 parts of defoamer. The prepared concrete has high toughness and durability, and has a high bond strength with the steel, with a compressive strength of 224.31MPa, a flexural strength of 47.45MPa, and a splitting tensile strength of 22.37MPa. The bonding strength reaches 8.92MPa, and the chloride ion impermeability level reaches level VI. Used in steel-concrete composite structures, it can effectively exert the synergistic performance between steel and concrete, make up for the poor bonding performance of steel and concrete, and the inability to give full play to their respective mechanical properties.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

A kind of C240 strength grade ultra-high performance fiber concrete containing coarse aggregate and preparation method thereof

ActiveCN107285708BImprove toughnessImprove deformation abilitySolid waste managementAggregate (composite)Modified carbon

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

A kind of high-performance fiber concrete of C90 strength grade and preparation method thereof

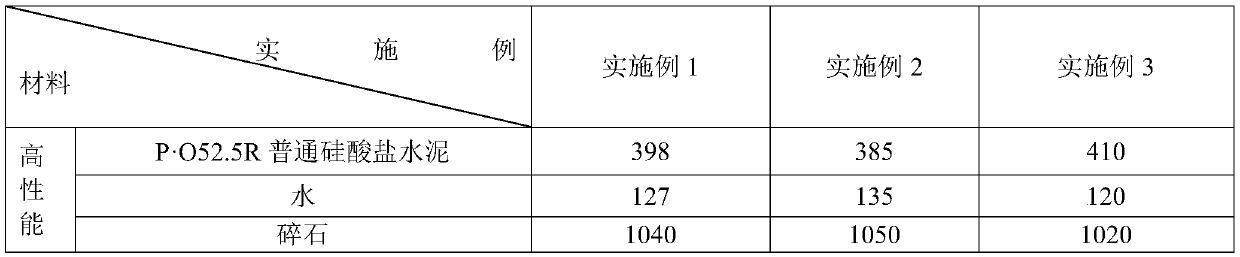

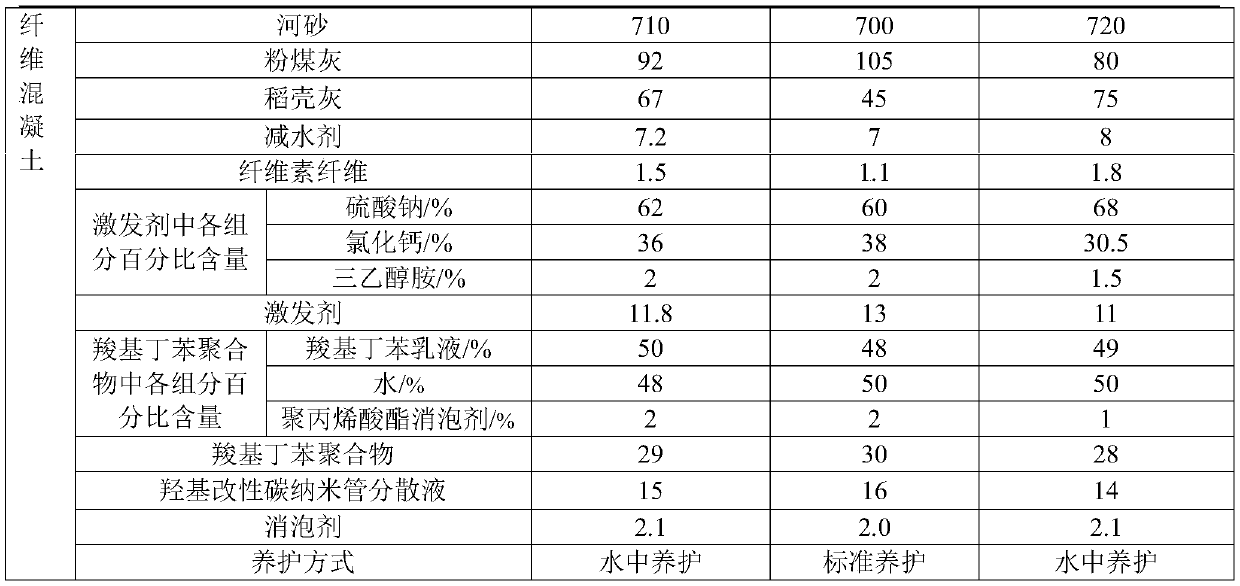

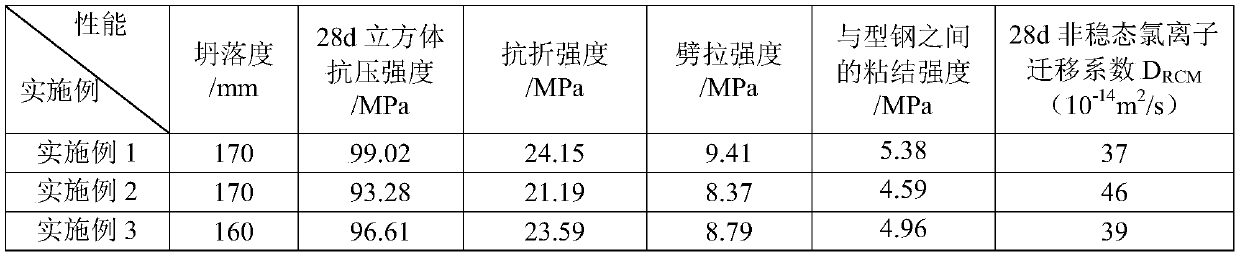

ActiveCN107298563BUnique fiber cavity structureImprove energy consumptionModified carbonCellulose fiber

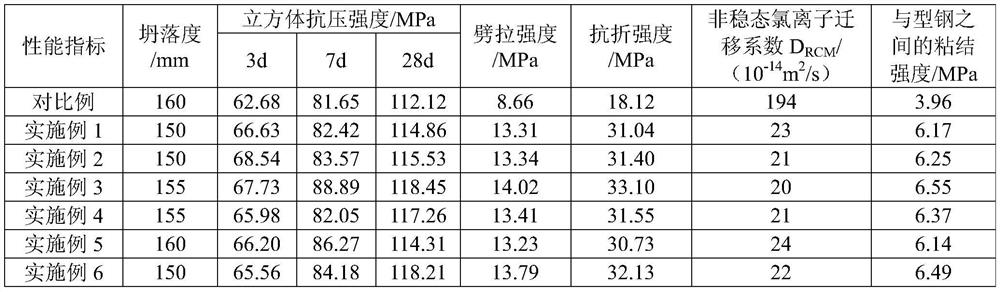

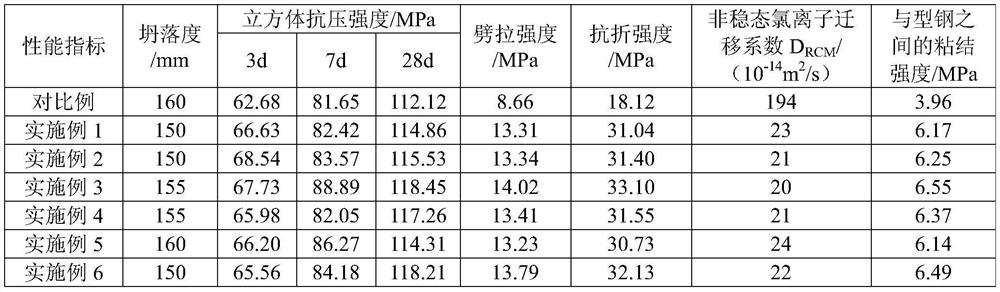

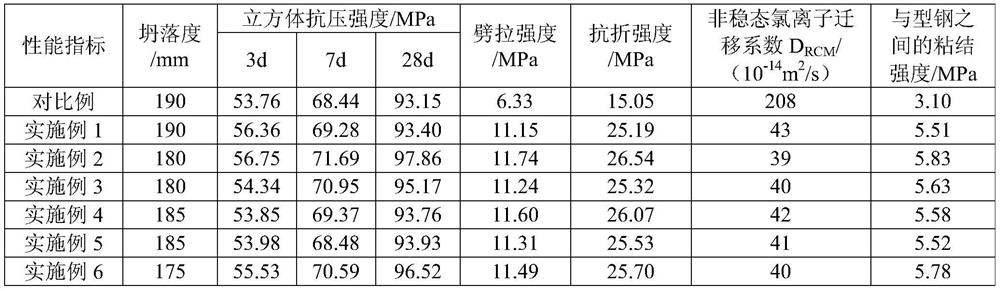

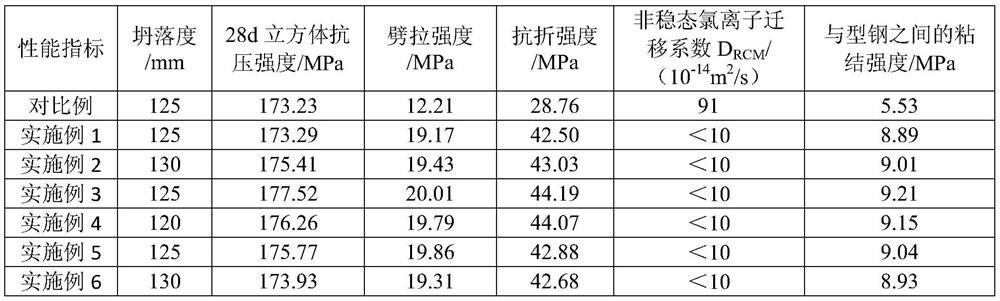

The invention discloses a high-performance fiber concrete of C90 strength grade and a preparation method thereof. The mass parts of the concrete are as follows: 385-410 parts of cement, 120-135 parts of water, 700-720 parts of river sand, and 1020 parts of gravel ‑1050 parts, 85‑105 parts of fly ash, 45‑75 parts of rice husk ash, 7‑8 parts of water reducing agent, 11‑13 parts of activator, 1.1‑1.8 parts of cellulose fiber, 28 parts of carboxylated styrene-butadiene polymer 30 parts, 14-16 parts of hydroxyl-modified carbon nanotube dispersion, 2.0-2.1 parts of defoamer. The prepared concrete has high toughness and excellent durability, and has a high bond strength with the section steel. Its 28d cubic compressive strength is not less than 93.28MPa, its splitting tensile strength is not less than 8.37MPa, and its flexural strength is not less than 21.19MPa, the bonding strength with the steel is not less than 4.59MPa, 28d unsteady chloride ion migration coefficient D RCM Not greater than 46×10 ‑14 m 2 / s. Used in steel-concrete composite structures, it can effectively exert the synergistic performance between steel and concrete, make up for the poor bonding performance of steel and concrete, and the inability to give full play to their respective mechanical properties.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

High-toughness and high-cohesiveness C200 ultrahigh-strength fiber concrete and preparation method thereof

ActiveCN113024190AImprove adhesionImprove flexural strengthSolid waste managementPolymer sciencePolyvinyl alcohol

The invention discloses high-toughness and high-cohesiveness C200 ultrahigh-strength fiber concrete and a preparation method thereof. The ultrahigh-strength fiber concrete is prepared from cement, sand, gravel, fly ash, straw ash, silica fume, nano silicon, water, a water reducing agent, an exciting agent, a defoaming agent, a shrinkage reducing agent, ramie fibers, basalt fibers, hydroxyl modified single-walled carbon nanotube dispersion liquid and a carboxyl modified polyvinyl alcohol polymer according to the mixing ratio of (507-518): (720-730): 945: (60-68): (80-90): (70-78): (4.6-4.8): (85-90): (16.8-18): (14.5-15): (2.5-2.9): (14.5-15): (6.2-6.4): (11.3-11.5): (31-32): (20.5-21.5). The materials are uniformly mixed at intervals through a layered stirring method, and preparation and maintenance are performed. The mechanical property, the bonding property with the profile steel, the cooperative working capacity and the durability of the concrete are all remarkably improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

High-toughness and high-cohesiveness C140-strength high-strength fiber concrete and preparation method thereof

ActiveCN113024212AImprove adhesionImprove flexural strengthSolid waste managementCement mixing apparatusPolymer sciencePolyvinyl alcohol

The invention discloses high-toughness and high-cohesiveness C140-strength high-strength fiber concrete and a preparation method thereof. The high-strength fiber concrete is prepared from cement, sand, gravel, fly ash, straw ash, silica fume, nano silicon, water, a water reducing agent, an exciting agent, a defoaming agent, a shrinkage reducing agent, ramie fibers, basalt fibers, a CaCO3 whisker and a carboxyl modified polyvinyl alcohol polymer according to the mixing ratio of (430-435): 720: 980: (80-85): (65-70): (35-40): (3.7-4.3): (115-120): (13-14): (13.5-14): (2-2.4): (10-11): (5.5-5.7): (9.3-9.6): (17.9-18.2): (21-23). The materials are evenly mixed at intervals through a layered stirring method, and discharging, forming and curing are conducted. The mechanical property of the concrete and the adhesive property and anti-permeability between the concrete and the profile steel are remarkably enhanced, and the cooperative work capacity of the concrete and the profile steel is further improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

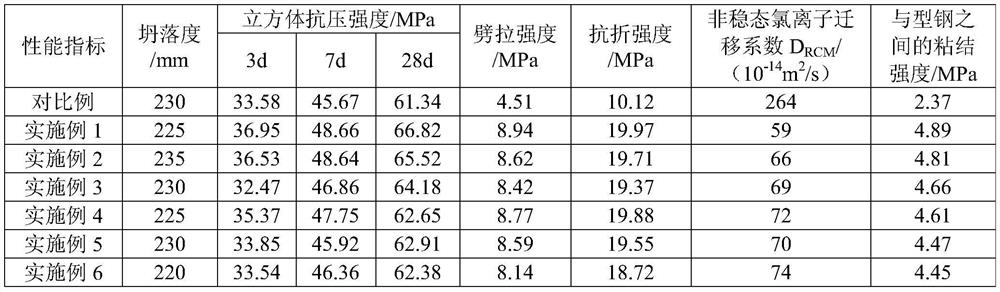

High-toughness and high-cohesiveness C230 ultrahigh-strength hybrid fiber concrete and preparation method thereof

ActiveCN113233862AImprove adhesionImprove flexural strengthCeramic shaping apparatusCement mixing apparatusPolymer sciencePolyvinyl alcohol

The invention discloses high-toughness and high-cohesiveness C230 ultrahigh-strength hybrid fiber concrete and a preparation method thereof. The high-toughness and high-cohesiveness C230 ultrahigh-strength hybrid fiber concrete is prepared from cement, sand, gravel, fly ash, straw ash, silica fume, nano silicon, water, a water reducing agent, an exciting agent, a defoaming agent, a shrinkage reducing agent, ramie fibers, basalt fibers, CaCO3 whiskers, a carboxyl modified polyvinyl alcohol polymer and nano titanium / graphene oxide dispersion liquid according to the mixing ratio of (540-545): (740-745): (870-880): (70-75): (95-100): (110-115): (5-5.2): (78-82): (18-19): (15.5-16): (2.6-3): (13-14): (7-7.2): (12.7-13): (19.5-19.7): (21-22): (39-42). The preparation method comprises the steps of uniformly mixing the materials by a layered stirring method, discharging, forming and curing. The concrete mechanics including the bonding performance and the durability between the profile steels are obviously improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

High-toughness high-cohesiveness C220 ultrahigh-strength hybrid fiber concrete and preparation method thereof

PendingCN113185209AImprove adhesionImprove flexural strengthSolid waste managementPolymer sciencePolyvinyl alcohol

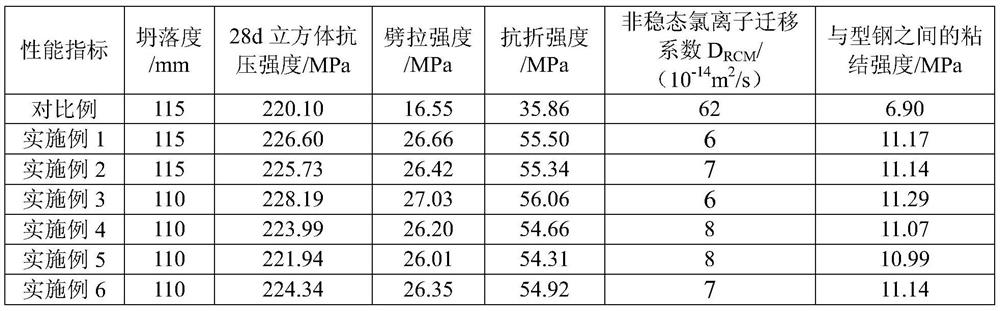

The invention discloses high-toughness and high-cohesiveness C220 ultrahigh-strength hybrid fiber concrete and a preparation method thereof. The high-toughness and high-cohesiveness C220 ultrahigh-strength hybrid fiber concrete is prepared from cement, sand, gravel, fly ash, straw ash, silica fume, nano silicon, water, a water reducing agent, an exciting agent, a defoaming agent, a shrinkage reducing agent, ramie fiber, basalt fiber, CaCO3 whisker, carboxyl modified polyvinyl alcohol polymer and nano titanium / graphene oxide dispersion liquid according to the mixing ratios of (535-540): (735-740): (880-890): (70-75): (90-100): (100-105): (4.8-5): (85-90): (17.5-18.5): (15-15.5): (2.6-3): (12-13): (6.7-7): (12.5-12.7): (19.2-19.5): (21-22): (36-39); and the materials are uniformly mixed by a layered stirring method, and preparation and curing are performed. The mechanical property and durability of the concrete and the bonding property between the concrete and profile steel are obviously improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

High-strength fiber concrete with high toughness and high cohesiveness c100 strength and its preparation method

The invention discloses a high-strength fiber concrete with high toughness and high cohesiveness C100 strength and a preparation method thereof. The mixing ratio includes: cement: sand: crushed stone: fly ash: straw ash: silica fume: nano silicon: water: water reducing Agent: activator: defoamer: shrinkage reducer: ramie fiber: basalt fiber: CaCO 3 Whiskers: carboxyl-modified polyvinyl alcohol polymer = 395‑405: 710: 1000: 90‑100: 40‑50: 18‑22: 2.8‑4: 130‑135: 10.5‑11: 12‑13: 1.8‑ 2.1:8‑9:5.1‑5.3:8.5‑8.7:17.5‑17.7:15‑17. Through the layered stirring method, the materials are mixed evenly at intervals, and the materials are discharged, formed and maintained. The mechanical properties of the concrete and the bonding performance with the profiled steel and the impermeability of the concrete are significantly enhanced, and the cooperating ability with the profiled steel is further improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

High-toughness high-cohesiveness C160-strength ultrahigh-strength fiber concrete and preparation method thereof

The invention discloses high-toughness and high-cohesiveness C160-strength ultrahigh-strength fiber concrete and a preparation method thereof. The concrete is prepared from cement, sand, broken stone, coal ash, straw ash, silica fume, nano silicon, water, exciting agent, defoaming agent, shrinkage reducing agent, ramie fiber, basalt fiber, hydroxyl modified single-walled carbon nanotube dispersion liquid and carboxyl modified polyvinyl alcohol polymer according to the mixing ratios of (470-480):(710-720):980:(75-80):(70-75): (45-55):(4-4.4):(100-105):(14-16):(13-13.5):(2.3-2.6):(12-13):(5.6-5.8):(10.2-10.4):(27-31):(17-19). The materials are evenly mixed at intervals through a layered stirring method, and discharging, forming and curing are conducted. The mechanic performance of the concrete, including the structural steel bonding performance and the durability, is remarkably improved, and the cooperative work capacity of the concrete and structural steel is enhanced.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

A kind of high-performance fiber concrete of c140 strength grade and preparation method thereof

ActiveCN107512888BUnique fiber cavity structureImprove energy consumptionSolid waste managementModified carbonCellulose fiber

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

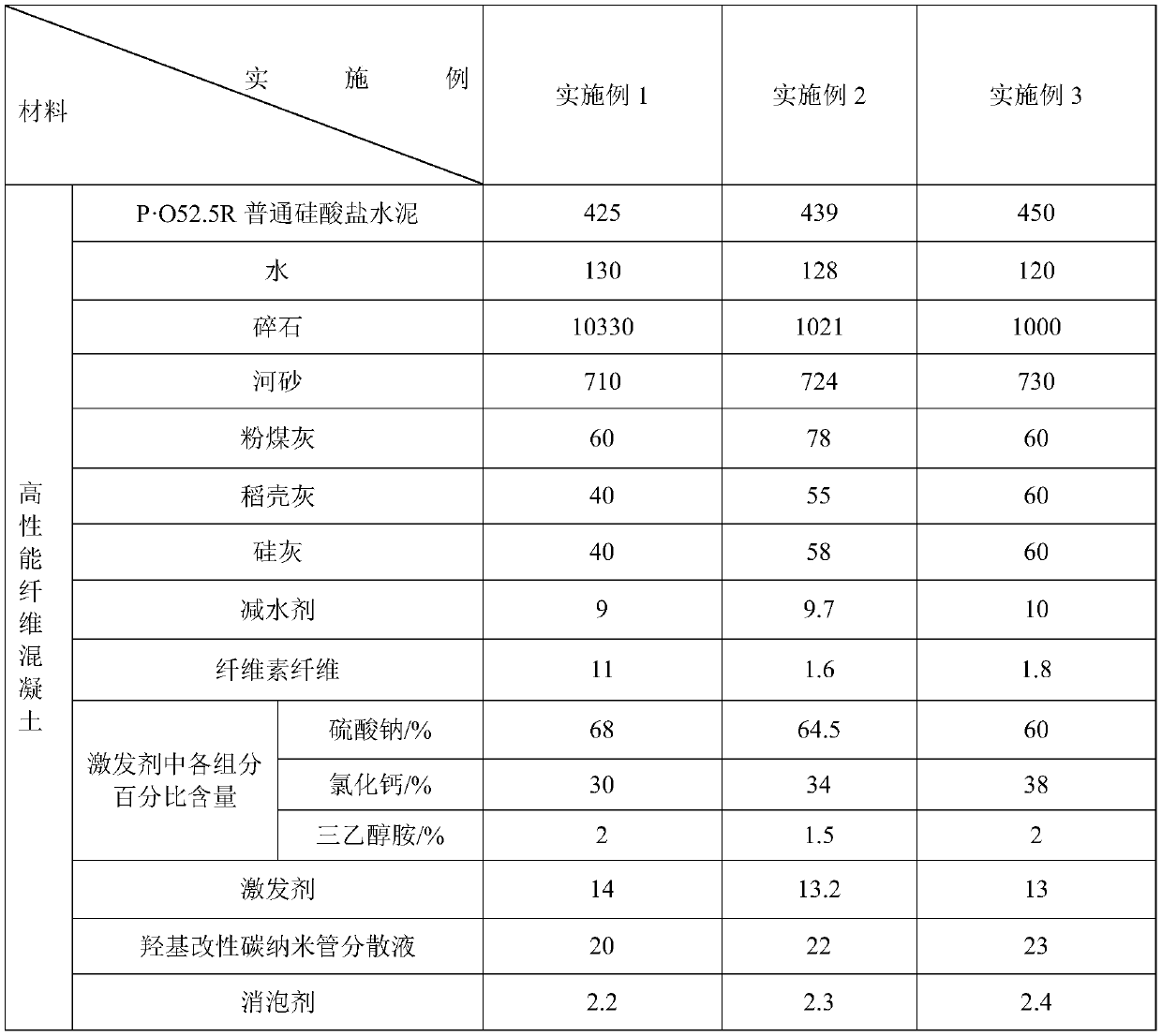

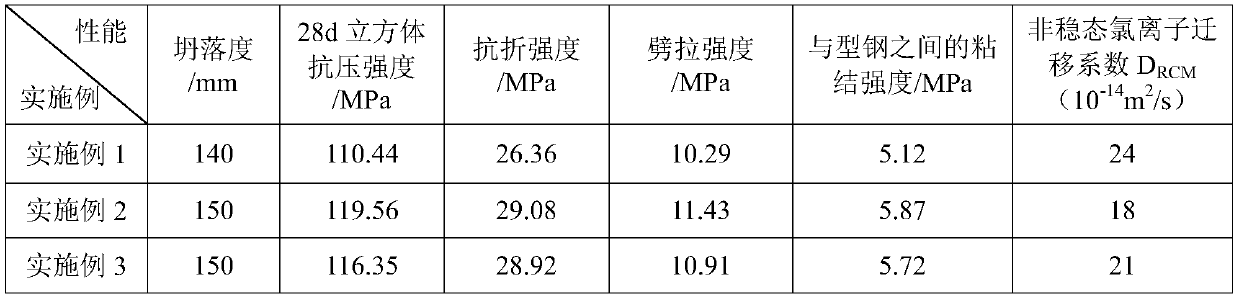

A kind of high-performance fiber concrete of C110 strength grade and its preparation method

ActiveCN107352915BUnique fiber cavity structureImprove energy consumptionModified carbonCellulose fiber

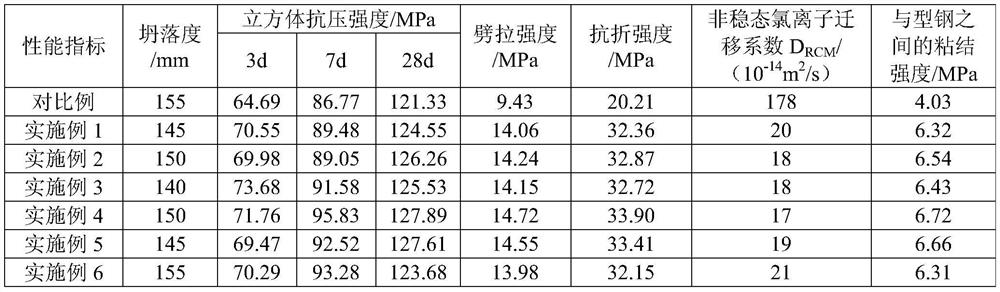

The invention discloses a high-performance fiber concrete of C110 strength grade and a preparation method thereof. The mass parts of the concrete are as follows: 425-450 parts of cement, 120-130 parts of water, 710-730 parts of river sand, and 1000 parts of gravel ‑1030 parts, 60‑90 parts of fly ash, 40‑60 parts of rice husk ash, 40‑60 parts of silica fume, 9‑10 parts of water reducing agent, 13‑14 parts of activator, 1.1‑1.8 parts of cellulose fiber, Hydroxyl-modified carbon nanotube dispersion liquid 20-23 parts, defoamer 2.2-2.4 parts. The prepared concrete has high toughness and excellent durability, and has high bonding strength with section steel. Used in steel-concrete composite structures, it can effectively exert the synergistic performance between steel and concrete, make up for the poor bonding performance of steel and concrete, and the inability to give full play to their respective mechanical properties.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com