Automobile interior polypropylene composition low in smell and density and preparation method thereof

A polypropylene composition and low-density technology, which is applied in the field of modified materials, can solve the problems of inability to remove odorous small molecules and cannot completely improve the odor of materials, and achieve the effect of avoiding instability and improving odor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific embodiment:

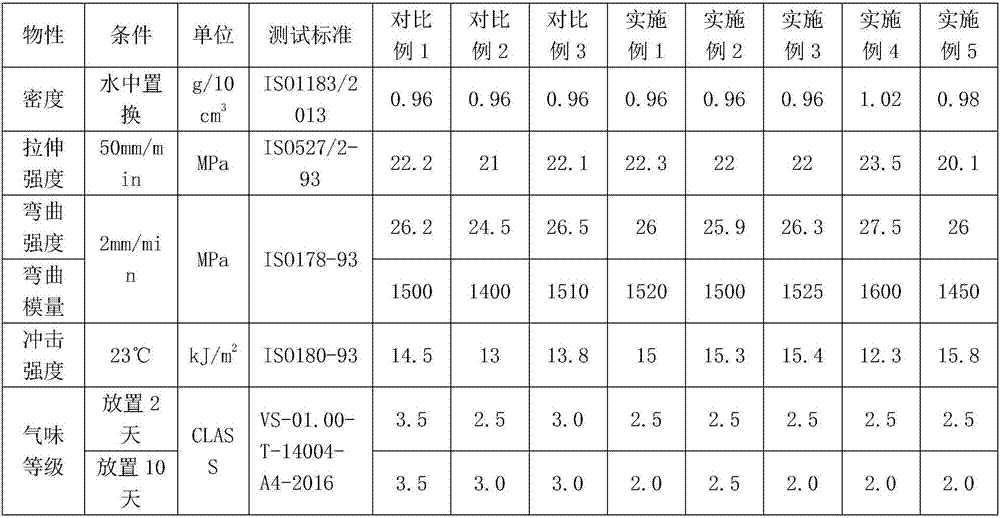

[0021] A kind of low-odor, low-density automotive interior polypropylene composition, the formula composition of embodiment 1-5 and comparative example 1-3 is as follows table 1:

[0022] Table 1 A low-odor, low-density automotive interior polypropylene composition formulation

[0023] raw material

Comparative example 1

Comparative example 2

Comparative example 3

Example 1

Example 2

Example 3

Example 4

Example 5

PP 7555KNE2

62

62

62

62

62

62

40

85

H9018

20

20

20

20

20

20

30

/

10

10

10

10

10

10

15

5

talcum powder

8

8

8

8

8

8

15

10

Antioxidant 1010

0.2

0.2

0.2

0.2

0.2

0.2

0.25

0.05

Antioxidant 168

0.2

0.2

0.2

0.2

0.2

0.2

0.25

0.05

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com