Intelligent cleaning factor for oil detergent and synthesis method thereof

A technology of cleaning factor and detergent, used in the petroleum industry, fuel additives, liquid carbon-containing fuels, etc., can solve problems such as abnormal engine operation, increased exhaust emissions, power interruption, etc., to maintain smooth flow, reduce friction, and stabilize performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

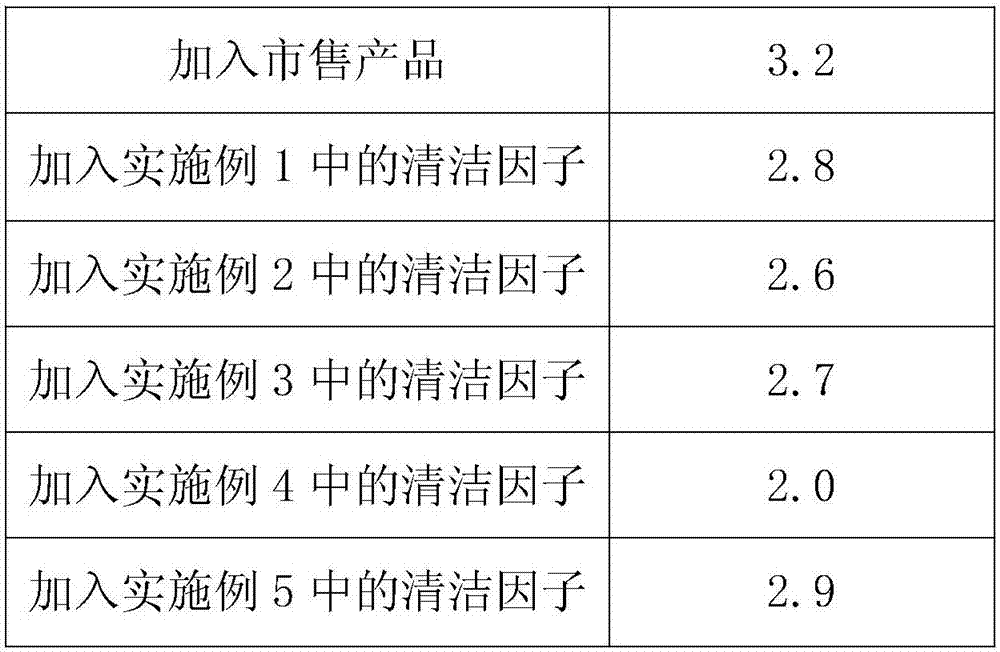

Embodiment 1

[0032] An intelligent cleaning factor for an oil detergent, prepared from the following raw materials under the action of an oxidizing agent: highly active polyisobutylene (PIB) with a molecular weight of 680, diethylenetriamine, polyether polyol (GP) with a molecular weight of 600 -306) and synthetic base oil PAO2; the oxidizing agent is di-tert-butyl peroxide.

[0033] Add 510 grams of highly active polyisobutylene (PIB) with a molecular weight of 680, 51.5 grams of diethylenetriamine, and 450 grams of polyether polyol (GP-306) with a molecular weight of 600 into a 5L reactor, and then add the oxidant di-tert-butyl 2.6 grams of peroxide, react at 140-150°C for 3 hours to obtain a reaction product, distill the reaction product under reduced pressure at 140-150°C until no liquid flows out from the distillation outlet, then add 1014 grams of synthetic base oil into the reaction kettle PAO2, stir well, that is.

Embodiment 2

[0035] An intelligent cleaning factor for an oil detergent, prepared from the following raw materials under the action of an oxidizing agent: highly active polyisobutylene (PIB) with a molecular weight of 680, diethylenetriamine, polyether polyol (GP) with a molecular weight of 600 -306) and synthetic base oil PAO2; the oxidizing agent is di-tert-butyl peroxide.

[0036] Add 680 grams of highly reactive polyisobutylene (PIB) with a molecular weight of 680, 51.5 grams of diethylenetriamine, and 600 grams of polyether polyol (GP-306) with a molecular weight of 600 into a 5L reactor, and then add the oxidant di-tert-butyl 6.2 grams of peroxide, react at 140-150°C for 4 hours to obtain a reaction product, distill the reaction product under reduced pressure at 140-150°C until no liquid flows out from the distillation outlet, then add 1337.7 grams of synthetic base oil into the reaction kettle PAO2, stir well, that is.

Embodiment 3

[0038] An intelligent cleaning factor for an oil detergent, prepared from the following raw materials under the action of an oxidizing agent: highly active polyisobutylene (PIB) with a molecular weight of 680, diethylenetriamine, polyether polyol (GP) with a molecular weight of 600 -306) and synthetic base oil PAO2; the oxidizing agent is di-tert-butyl peroxide.

[0039] Add 680 grams of highly active polyisobutylene (PIB) with a molecular weight of 680, 51.5 grams of diethylenetriamine, and 480 grams of polyether polyol (GP-306) with a molecular weight of 600 into a 5L reactor, and then add the oxidant di-tert-butyl 5.2 grams of peroxide, react at 140-150°C for 3 hours to obtain a reaction product, distill the reaction product under reduced pressure at 140-150°C until no liquid flows out from the distillation outlet, then add 1216.7 grams of synthetic base oil into the reaction kettle PAO2, stir well, that is.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com