Lasting, antibacterial and sweat-proof non-ironing finishing liquid of cotton fabric, and finishing technology thereof

A non-iron finishing and anti-sweat technology, which is applied in the biochemical treatment of velvet protectant/mothproof agent, fiber treatment, plant fiber, etc. It can solve the problems of antibacterial performance not lasting and effective, poor wearing performance of fabrics, yellowing of clothes, etc. problem, to achieve the effect of improving anti-shrinkage and anti-wrinkle effect, anti-wrinkle and non-ironing performance, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

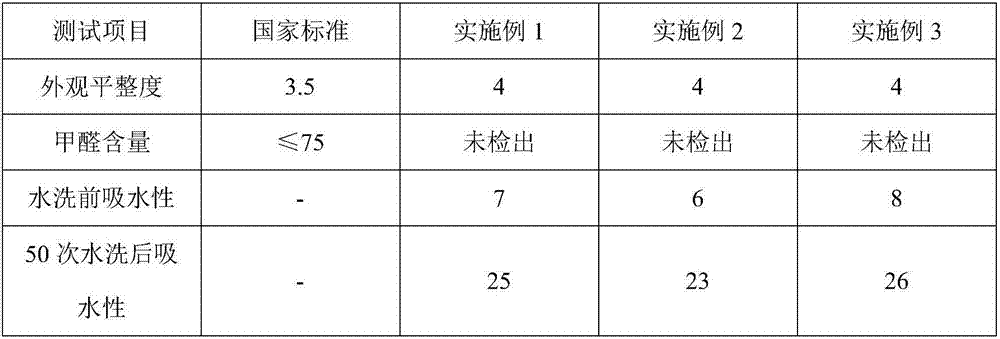

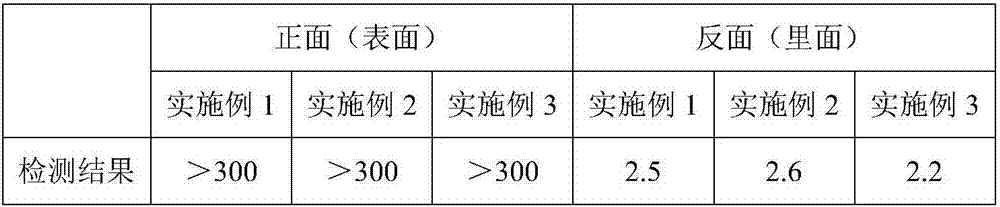

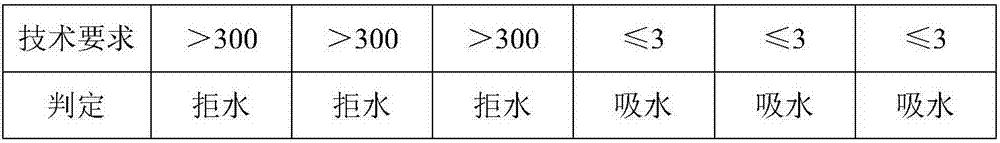

Examples

Embodiment 1

[0026] A long-lasting antibacterial, anti-perspiration and non-ironing finishing solution for cotton fabrics, comprising the following raw materials in parts by weight: 30 parts of honeysuckle extract, 30 parts of Houttuynia cordata extract, 30 parts of pomegranate peel extract, 3 parts of gum arabic, nano 10 parts of zinc oxide, 10 parts of nano-silver powder, 6 parts of chitosan, 5 parts of non-ionic softener, 6 parts of carboxymethyl cellulose, 2 parts of non-ionic penetrating agent JFC, 6 parts of waterproofing agent EF-24, low-temperature fixing type 4 parts of water-based polyacrylate.

[0027] The honeysuckle extract is prepared by drying and pulverizing honeysuckle and extracting twice with 20% ethanol solution at a solid-to-liquid ratio of 1:10 at a temperature of 60° C. for 1 hour each time. After centrifugation, the extracts are combined and concentrated.

[0028] The Houttuynia cordata extract is obtained by refluxing and extracting Houttuynia cordata cut into sect...

Embodiment 2

[0042] A long-lasting antibacterial, anti-perspiration and non-ironing finishing solution for cotton fabrics, comprising the following raw materials in parts by weight: 20 parts of honeysuckle extract, 20 parts of Houttuynia cordata extract, 20 parts of pomegranate peel extract, 2 parts of gum arabic, nano 5 parts of zinc oxide, 5 parts of nano-silver powder, 4 parts of chitosan, 3 parts of non-ionic softener, 3 parts of carboxymethyl cellulose, 1 part of non-ionic penetrating agent JFC, 4 parts of waterproofing agent EF-24, low-temperature fixing type 2 parts of water-based polyacrylate.

[0043] The honeysuckle extract is prepared by drying and pulverizing honeysuckle and extracting twice with 20% ethanol solution at a solid-to-liquid ratio of 1:10 at a temperature of 60° C. for 1 hour each time. After centrifugation, the extracts are combined and concentrated.

[0044] The Houttuynia cordata extract is obtained by refluxing and extracting Houttuynia cordata cut into section...

Embodiment 3

[0058] A long-lasting antibacterial antiperspirant and non-ironing finishing solution for cotton fabrics, comprising the following raw materials in parts by weight: 25 parts of honeysuckle extract, 25 parts of Houttuynia cordata extract, 25 parts of pomegranate peel extract, 2.5 parts of gum arabic, nano 8 parts of zinc oxide, 8 parts of nano-silver powder, 5 parts of chitosan, 4 parts of non-ionic softener, 5 parts of carboxymethyl cellulose, 1.5 parts of non-ionic penetrant JFC, 5 parts of waterproofing agent EF-24, low temperature 3 parts of fixed water-based polyacrylate.

[0059] The honeysuckle extract is prepared by drying and pulverizing honeysuckle and extracting twice with 20% ethanol solution at a solid-to-liquid ratio of 1:10 at a temperature of 60° C. for 1 hour each time. After centrifugation, the extracts are combined and concentrated.

[0060] The Houttuynia cordata extract is obtained by refluxing and extracting Houttuynia cordata cut into sections with 50% et...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com