Friction wear testing device for online measuring abrasion loss in vacuum environment

A friction and wear test, vacuum environment technology, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems of reduced movement accuracy of parts, difficult material wear resistance, material can not be replaced, etc., to achieve low cost and good sealing performance , the effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

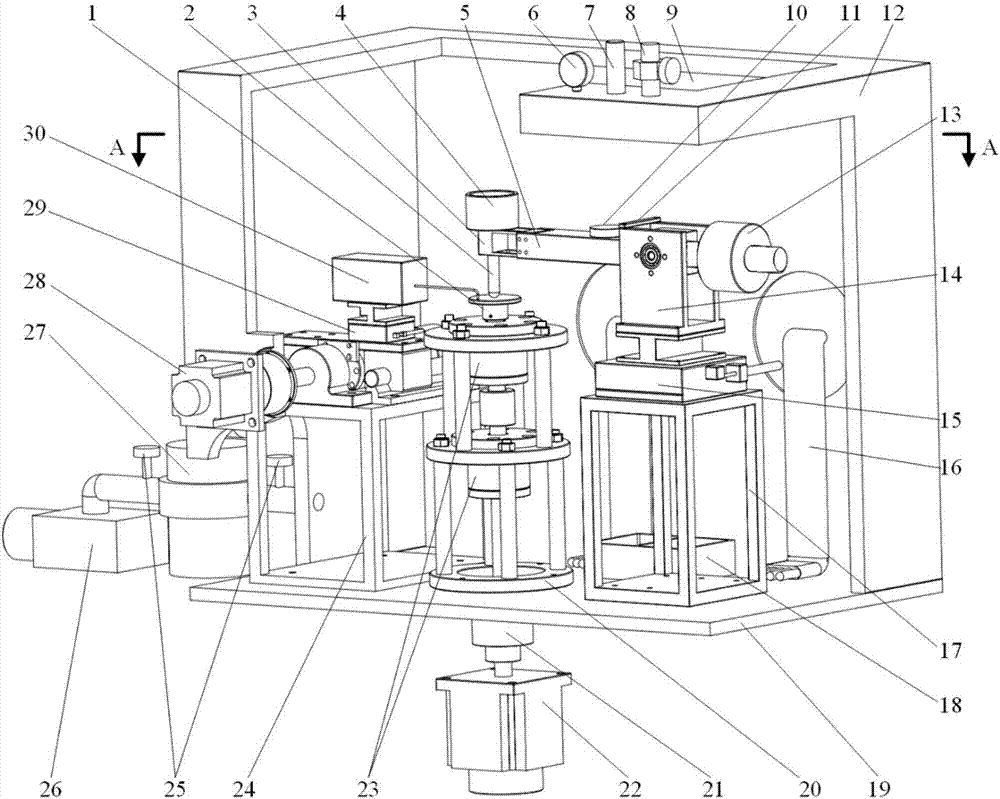

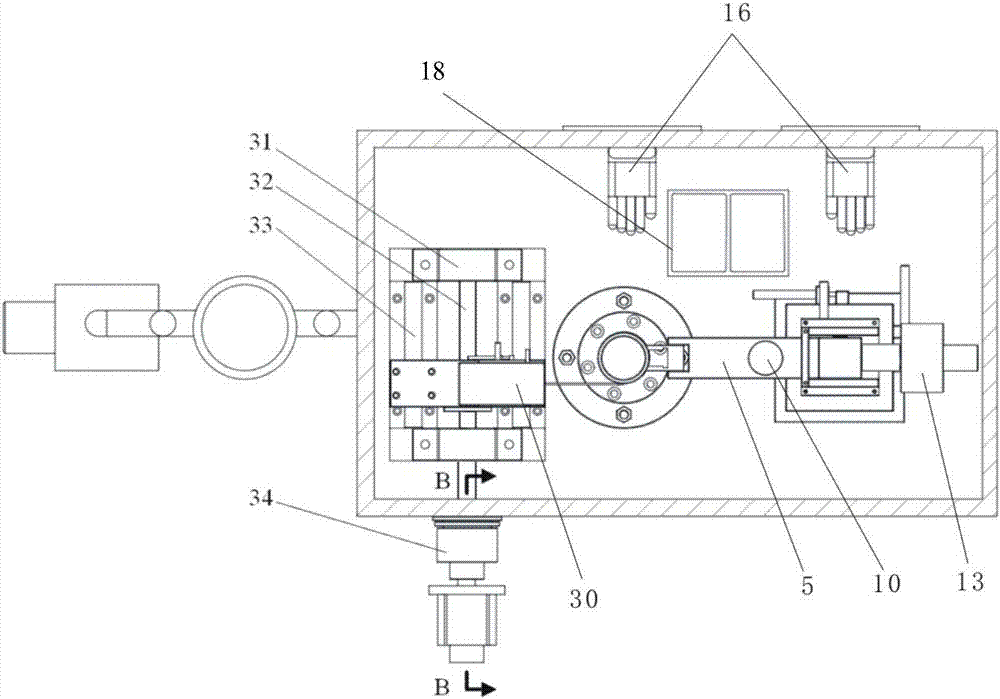

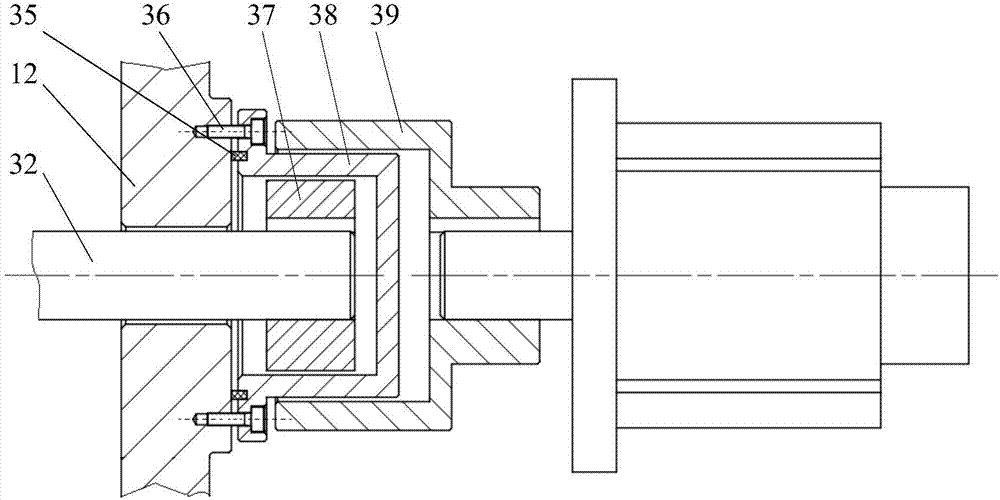

[0019] The present invention is a friction and wear test device for on-line measurement of wear amount in a vacuum environment, such as figure 1 As shown, it includes a coefficient of friction measuring mechanism and a wear surface profile measuring mechanism arranged on the base plate 19; a vacuum cover 12 is also included, and the vacuum cover 12 is covered on the base plate 19, so that the relationship between the vacuum cover 12 and the base plate 19 form a vacuum environment.

[0020] Coefficient of friction measuring mechanism, such as figure 1 As shown, it includes a bracket a17 arranged on the bottom plate 19, a three-coordinate translation stage a15 is arranged on the top of the bracket a17, and a support 14 is connected to the three-coordinate translation platform a15, and the upper surface of the support 14 is provided with a limi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com