Micro-nano optical detection device and micro-nano optical detection system

A light detection device and light intensity detection technology, applied in the field of optical detection, can solve the problems of not reaching the micro-nano size, single use, large modules, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

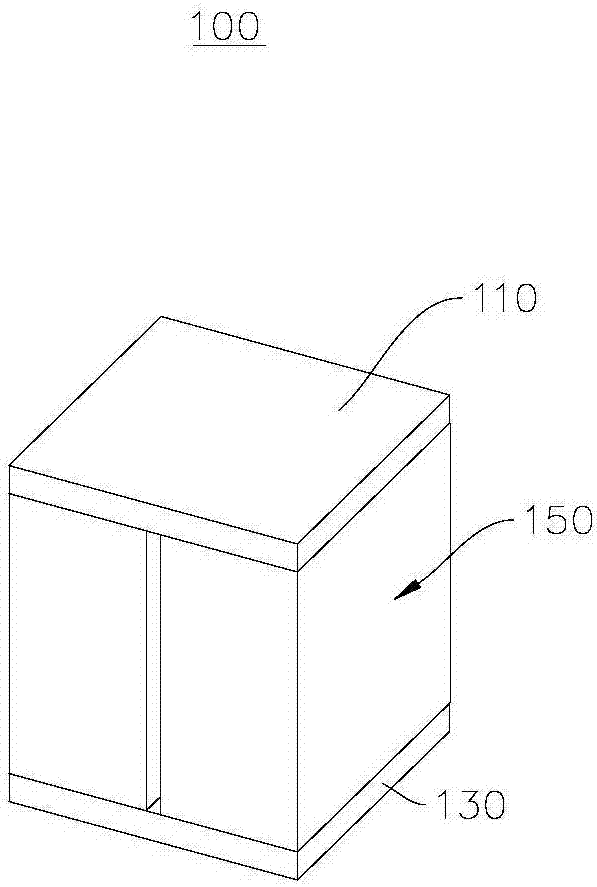

[0035] see figure 1 , figure 1 It shows a schematic diagram of a micro-nano photodetection device 100 provided by this embodiment.

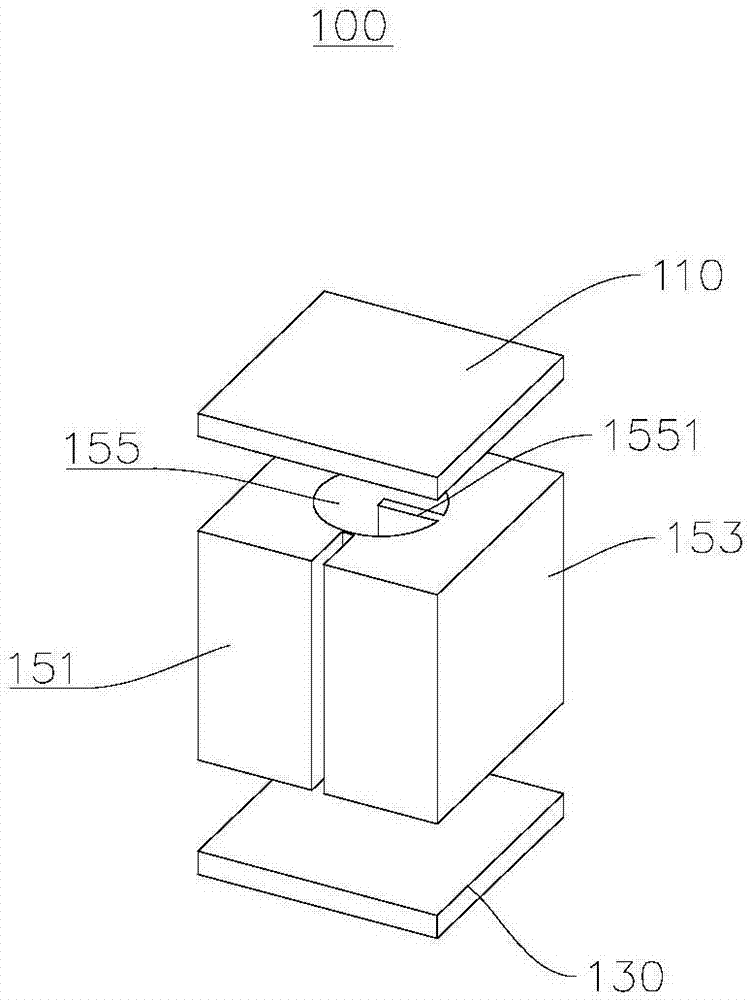

[0036] The micro-nano photodetection device 100 includes a first cover 110 , a second cover 130 and a conductive component 150 . see figure 2 , figure 2A schematic diagram of the assembly structure of the micro-nano photodetection device 100 provided in this embodiment is shown. Wherein, the first cover plate 110 and the second cover plate 130 are disposed opposite to each other, the first cover plate 110 is disposed above the conduction assembly 150, and the second cover plate 130 is disposed below the conduction assembly 150, Both the first cover plate 110 and the second cover plate 130 are in good contact with the conductive component 150 to prevent the electromagnetic wave (in this embodiment, the electromagnetic wave is light) transmitted through the conductive component 150 from leaking.

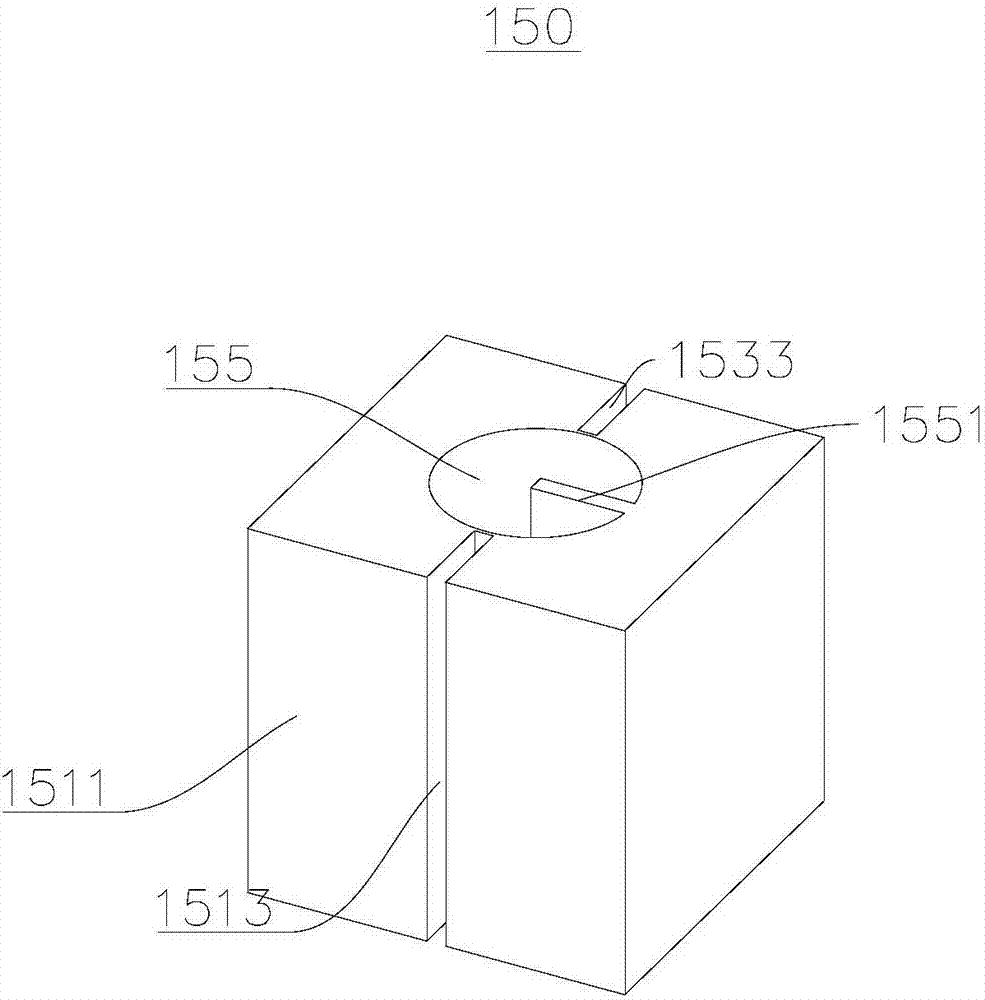

[0037] see image 3 , image 3 A first vie...

no. 2 example

[0055] This embodiment provides a light detection system 200, please refer to Figure 6 , Figure 6 A schematic diagram of the light detection system 200 provided in this embodiment is shown.

[0056] The light detection system 200 provided in this embodiment includes the micro-nano light detection device 100 and the spectrum analysis device 230 in the first embodiment. The spectrum analysis device 230 is disposed on one side of the second waveguide 153 of the micro-nano light detection device 100 , and is used for detecting and analyzing the spectrum of the light passing through the micro-nano light detection device 100 .

[0057] The micro-nano light detection device 100 in this embodiment is slightly different from the micro-nano light detection device 100 in the first embodiment, please refer to Figure 7 , Figure 7 A schematic diagram of the micro-nano photodetection device 100 provided in this embodiment is shown. Both the first cover plate 110 and the second cover ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com