Leather shoes made of sharkskin

A shark skin and leather shoe technology, applied in the field of shoes, can solve problems such as difficulty in meeting requirements, insufficient softness, and non-waterproof

Active Publication Date: 2017-11-21

ZHEJIANG IND & TRADE VACATIONAL COLLEGE

View PDF5 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Traditional shoes are too rigid, bulky, and poorly elastic, so they cannot be adapted to many occasions. Moreover, the feet inside the shoes are easily bound by the upper and cause discomfort. The upper has insufficient air permeability and is prone to stuffiness. In severe cases, beriberi will occur, and the softness is insufficient. In addition, the traditional fabrics have poor moisture absorption and perspiration effects, are not waterproof, and are not suitable for the current

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

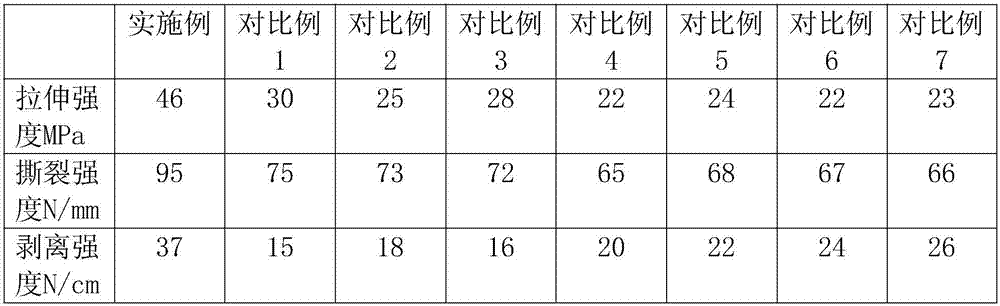

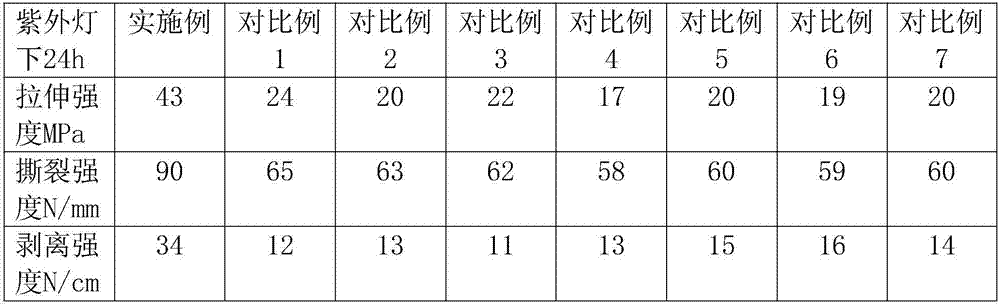

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses leather shoes made of sharkskin. Each leather shoe comprises a sole and a vamp, wherein the vamp is positioned on the sole; the vamp is prepared by a following method with the steps of: firstly carrying out degreasing pretreatment on the sharkskin by using degreasing liquid, then carrying out tanning treatment by using special tanning liquid, then adding greasing liquid to carry out greasing finishing and finally preparing into the shark leather; and then indirectly coating by using a release paper method to prepare polyurethane artificial leather as a sole lining, after treating the shark leather and the polyurethane artificial leather, using a special hot-melt adhesive to bond the shark leather and the polyurethane artificial leather together, and then carrying out washing, drying, cutting and polishing to prepare into the vamp of the leather shoes made of sharkskin. The vamp is comfortable and soft, strong in air permeability, can resist water, is high in peeling strength and tensile strength, has certain antibacterial and mildew-proof effects and also has certain heat resistance.

Description

technical field [0001] The present invention relates to a kind of shoe, more specifically relates to a kind of sharkskin leather shoe. Background technique [0002] Shoes are a kind of common daily necessities, and shoes are made up of two parts, vamp and sole, and vamp provides a covering for the foot to accommodate the pin and place the pin well relative to the sole structure. In addition, the upper also has the function of foot protection and ventilation, so that the feet can cool down and remove sweat. [0003] Due to the overall rigidity, bulkiness, and poor elasticity of traditional shoes, they cannot be adapted to many occasions. Moreover, the feet inside the shoes are easily bound by the upper and cause discomfort. The upper has insufficient air permeability and is prone to stuffiness. In severe cases, beriberi will occur, and the softness is insufficient. In addition, the traditional fabrics have poor moisture absorption and perspiration effects, are not waterproof...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): A43B1/02C14C1/00C14C1/08C14C3/08C14C9/02C14C13/00

CPCA43B1/02C14C1/00C14C1/08C14C3/08C14C9/02C14C13/00

Inventor 刘剑周章添吴学坎王程

Owner ZHEJIANG IND & TRADE VACATIONAL COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com