Hot melting damping fin punching and cutting device and punching method thereof

A damping sheet and hot-melt type technology, which is applied in the field of automobile damping, can solve the problems of serious burrs and short service life of conveyor belts, and achieve the effects of reducing harmful gases, improving bonding force, and avoiding burrs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

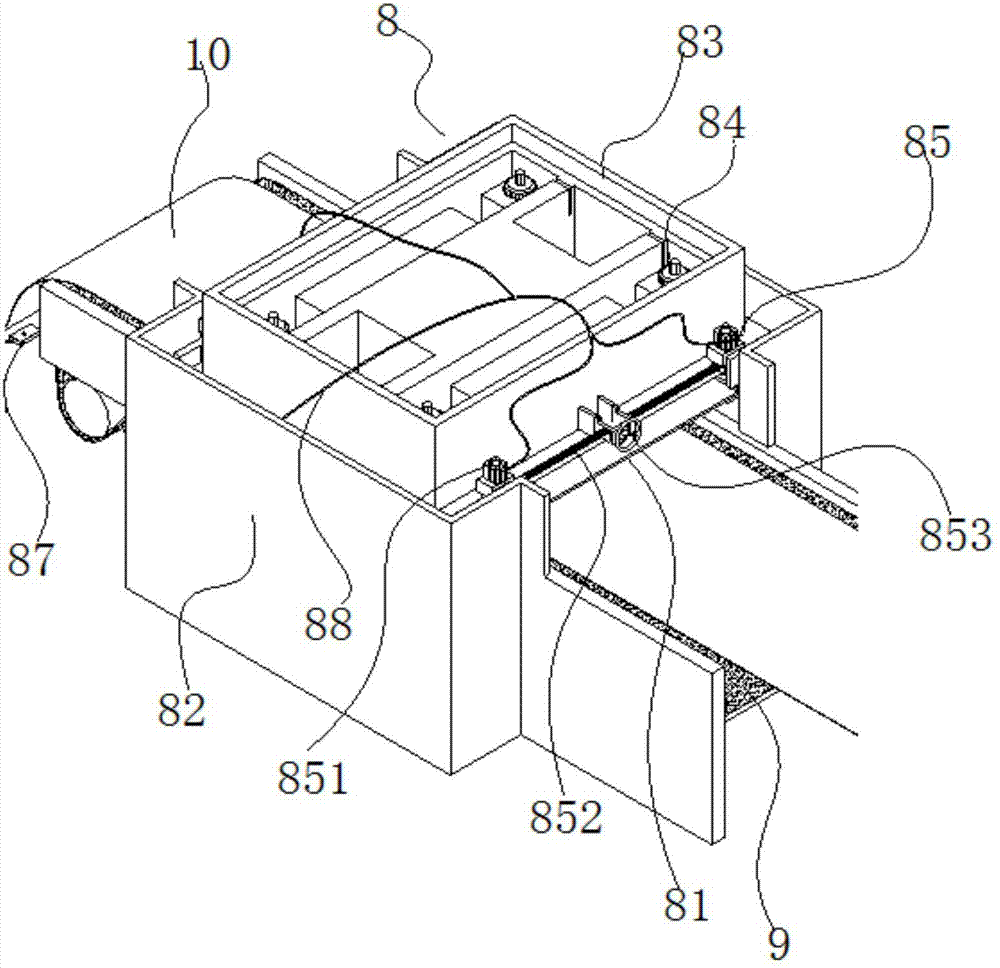

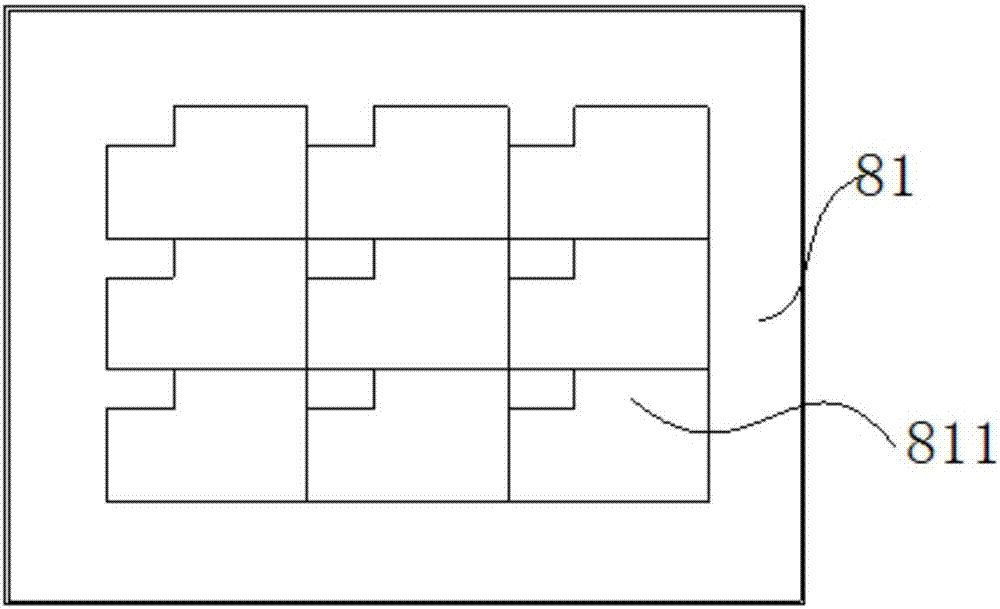

[0062] The hot-melt type damping plate stamping and cutting device of this embodiment, such as figure 1 As shown, it includes a stamping and cutting device body 8 and a special conveyor belt 9 passing through the stamping and cutting device body 8 to transmit the hot-melt damping sheet 10; wherein: the stamping and cutting device body 8 includes a dedicated conveyor belt 9 The two support platforms 82 on the side, the stamping platform 83 and the lifting height adjustment mechanism 84 that are laid flat and fixed on the sides of the two support platforms 82; the stamping platform 83 is connected to the bottom of the stamping platform 83 through the lifting height adjustment mechanism 84 Die 81 installed. The special conveyor belt 9 is a nylon conveyor belt mainly made of nylon material, the tear strength is greater than 20Mpa, and the elongation at break is greater than 400%, so that it is suitable for the hot-melt type damping sheet 10 of the present invention, and the hot-me...

Embodiment 2

[0071] The hot-melt type damping sheet stamping and cutting device of this embodiment has the same basic structure as that of Embodiment 1, the difference and improvement is that: the lifting height adjustment mechanism 84 is four lifting screws symmetrically arranged at the four corners of the stamping table 83 ; The bottom of the front end of the dedicated conveyor belt 9 is provided with a damping plate induction mechanism 87 . The ingredients of the hot-melt damping sheet 10 include 100 kilograms of superfine light calcium powder with a particle size of 0.5 to 1 μm, 500 kilograms of superfine heavy calcium powder with a particle size of 0.5 to 1 μm, 70 kilograms of mica powder, 60 kilograms asphalt, 8 kg of asphalt modifiers such as SBS styrene or EVA ethylene-vinyl acetate copolymer, 4 kg of softeners such as vegetable oil, rubber oil, rubber rolling oil, etc., 3 kg of fibers such as hemp fiber, aramid fiber.

[0072] The processing method of the hot-melt type damping sh...

Embodiment 3

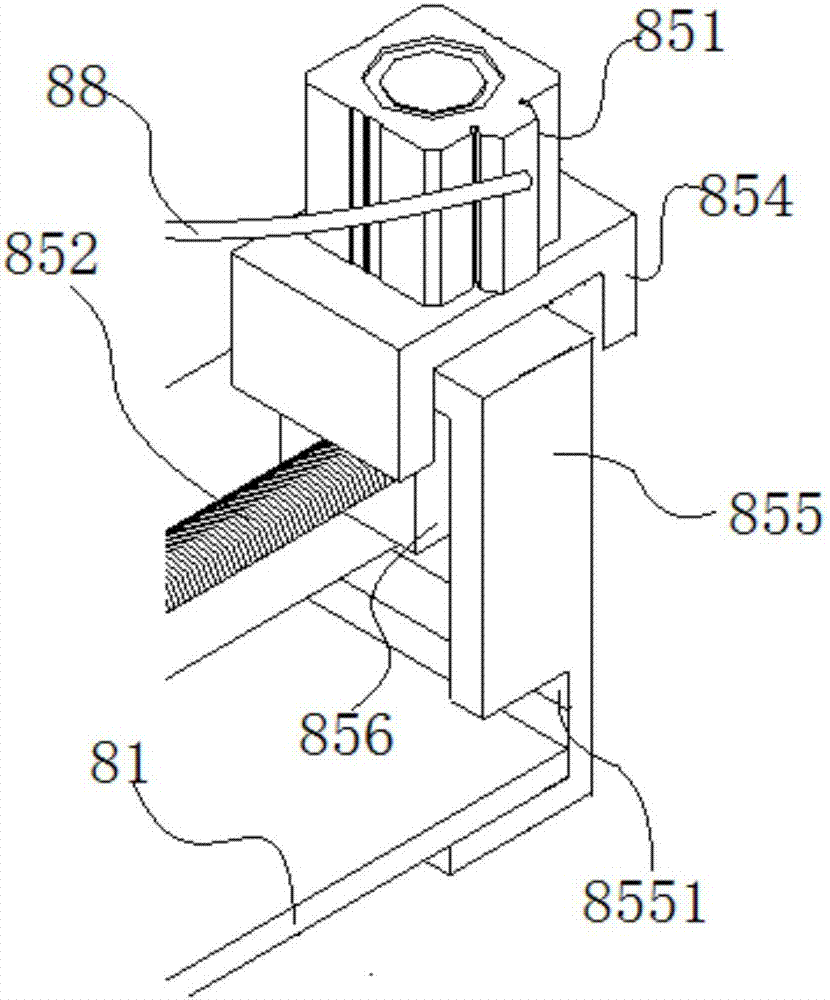

[0080] The stamping and cutting device for the hot-melt damping sheet of this embodiment has the same basic structure as that of Embodiment 2, the difference and improvement lies in that it also includes two knives that are respectively arranged on the front and rear sides of the stamping table 83 and directly above the special conveyor belt 9 Die width adjustment mechanism 85. The ingredients of hot-melt damping sheet 10 include 175 kg of ultrafine light calcium powder with a particle size of 0.5-1 μm, 525 kg of ultra-fine heavy calcium powder with a particle size of 0.5-1 μm, 75 kg of mica fine powder, 70 kg asphalt, 9 kg of asphalt modifiers such as SBS styrene or EVA ethylene-vinyl acetate copolymer, 6 kg of softeners such as vegetable oil, rubber oil, rubber rolling oil, etc., 4 kg of fibers such as hemp fiber, aramid Fiber, wherein: the processing steps of superfine light calcium powder or superfine heavy calcium powder are:

[0081] Step 1. Mixing: fully mix commercial...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength at break | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com