Agricultural omnidirectional wheel

A technology of omnidirectional wheels and axles, which is applied in electric steering mechanism, vehicle maintenance, power plant, etc., can solve the problems of large turning radius and poor steering precision, and achieve the effect of reliable action, large force and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

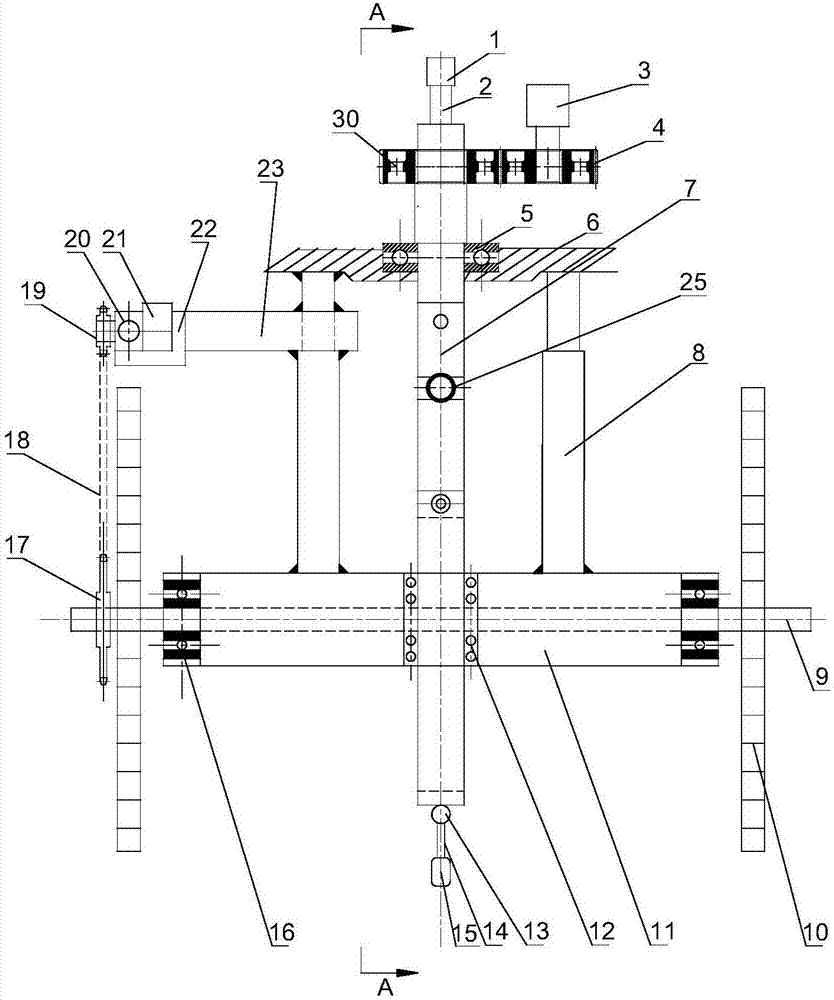

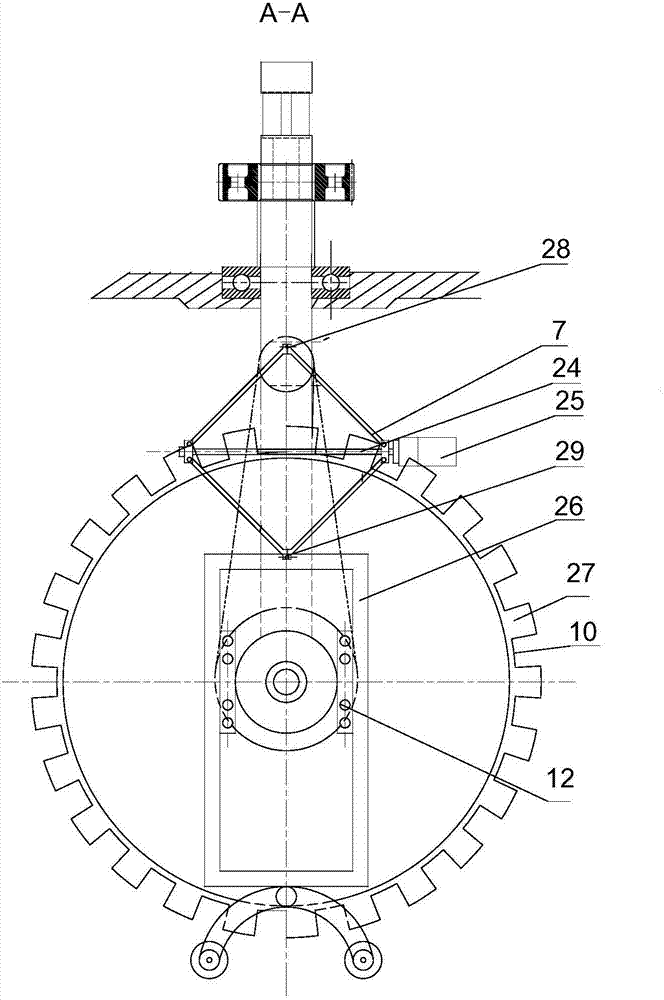

[0024] see figure 1 and figure 2 , the agricultural omnidirectional wheel in the illustration is a preferred solution of the present invention, including an angle sensor 1, a steering shaft 2, a steering motor 3, a pinion 4, a thrust bearing 5, a frame base 6, a jack 7, a pillar 8, and a wheel shaft 9. Traveling wheel 10, main shaft sleeve 11, slide rail 12, first hinge 13, U-shaped bracket 14, steering support wheel 15, rolling bearing 16, large sprocket 17, chain 18, small sprocket 19, reducer 20, Drive motor 21, drive motor support 22, transverse support 23, adjusting screw rod 24, variable speed motor 25, steering bracket 26, anti-skid tooth 27, second hinge 28, third hinge 29 and bull gear 30.

[0025] Specifically, the agricultural omnidirectional wheel of this embodiment is divided into four parts: a traveling mechanism composed of traveling wheels 10, a traveling driving mechanism, a steering mechanism, and a jacking mechanism, wherein two sets of traveling wheels 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com