Electroless gold plating bath

An electroless gold plating and chemical technology, applied in liquid electroless plating, metal material coating process, coating and other directions, can solve problems such as large adverse environmental impact, and achieve the effect of improving plating stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

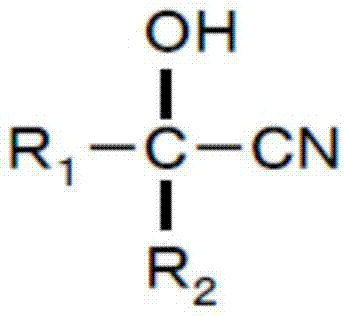

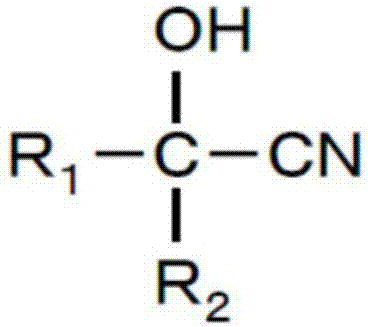

Method used

Image

Examples

Embodiment 1

[0080] In this example, in order to investigate that the cyanohydrin compound acts effectively as a stabilizer of the electroless gold plating bath, the stability, appearance, and plating film formation speed (plating speed) were investigated by the following methods.

[0081] (stability)

[0082] The gold-plating baths described in Table 1 were prepared and placed in a container, heated up to the respective temperatures described in Table 1, and then kept at the above temperatures for 24 hours. The temperature (holding temperature) in Table 1 is different because the reduction reaction temperature of Au is different due to the type of reducing agent.

[0083] While maintaining the above-mentioned temperature, the state of the plating solution was visually observed to check whether there was a sign of plating bath decomposition that gold was deposited into the container. The evaluation of no gold precipitation was 0 (good stability), and the evaluation of gold precipitation w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com