A prefabricated reinforced concrete frame variable section column and its construction method

A technology of reinforced concrete and variable cross-section columns, which is applied in the field preparation of formwork/formwork/work frames, building components, construction, etc. It can solve problems such as the sleeve connection is not firm, achieve strong promotion and application value, and facilitate construction , good strength and stiffness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

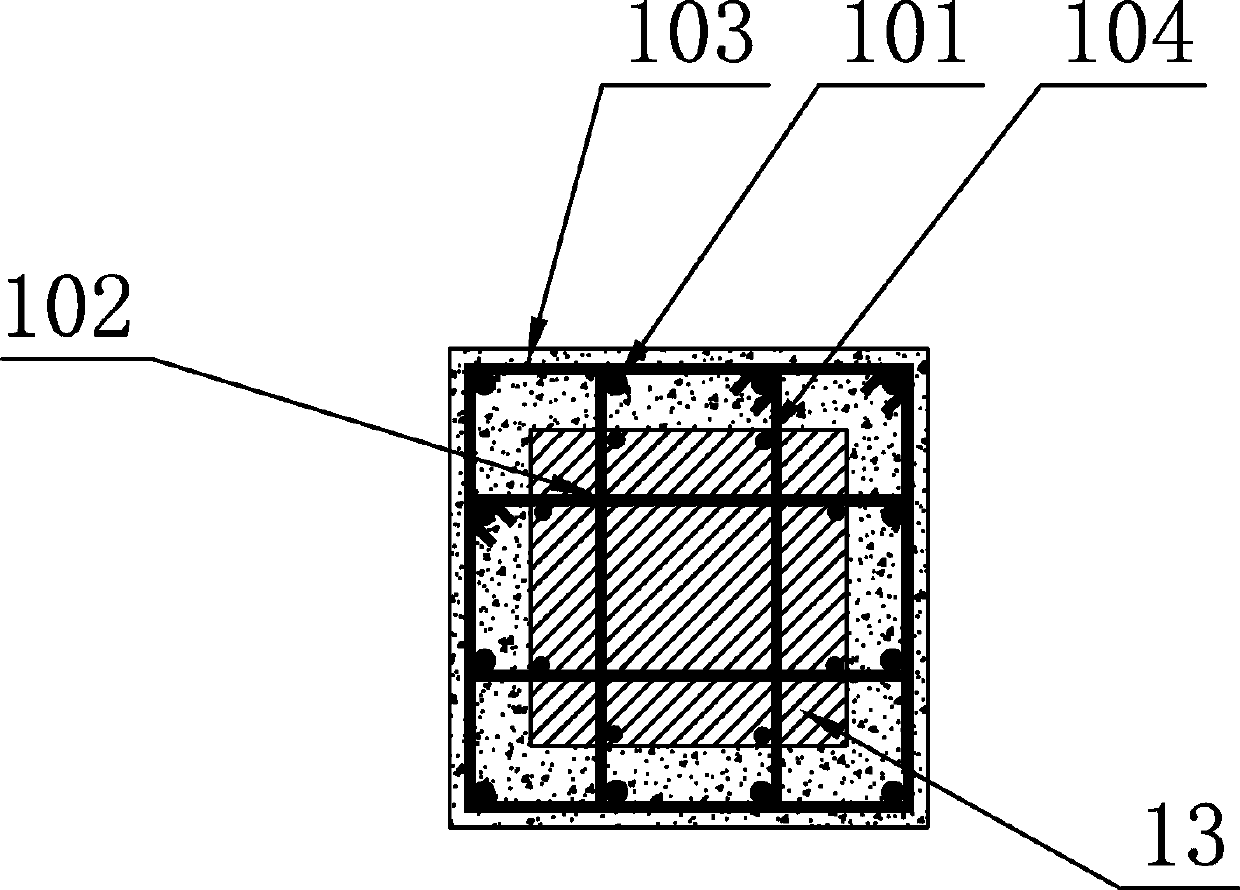

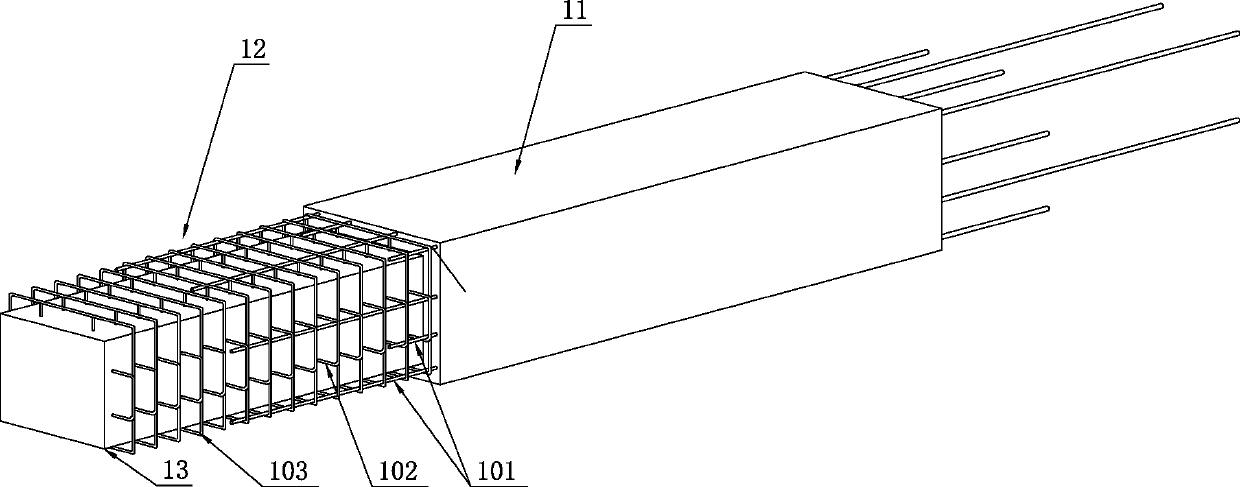

[0056] Such as figure 1 As shown, a prefabricated reinforced concrete frame variable cross-section column of the present invention includes an upper column section 11 and a lower section 12 of the column; The column inner stirrups 102 and peripheral stirrups 103 are bound firmly to each other; the longitudinal bars 101 protrude from the top of the column; the size of the concrete layer around the lower section 12 of the column is uniformly reduced to form a core column 13, and the exposed longitudinal bars 101, peripheral stirrups 103 and parts The inner stirrup 102 of the column makes the entire column a column with a variable cross-section with a large upper part and a smaller lower part; the inner stirrups of the lower section of the column 12 protrude from the periphery of the core column 13 and are integrated with the outer stirrups 103 of the column; the 12 longitudinal bars of the lower section of each column 101 and the longitudinal reinforcement 101 of the upper secti...

Embodiment 2

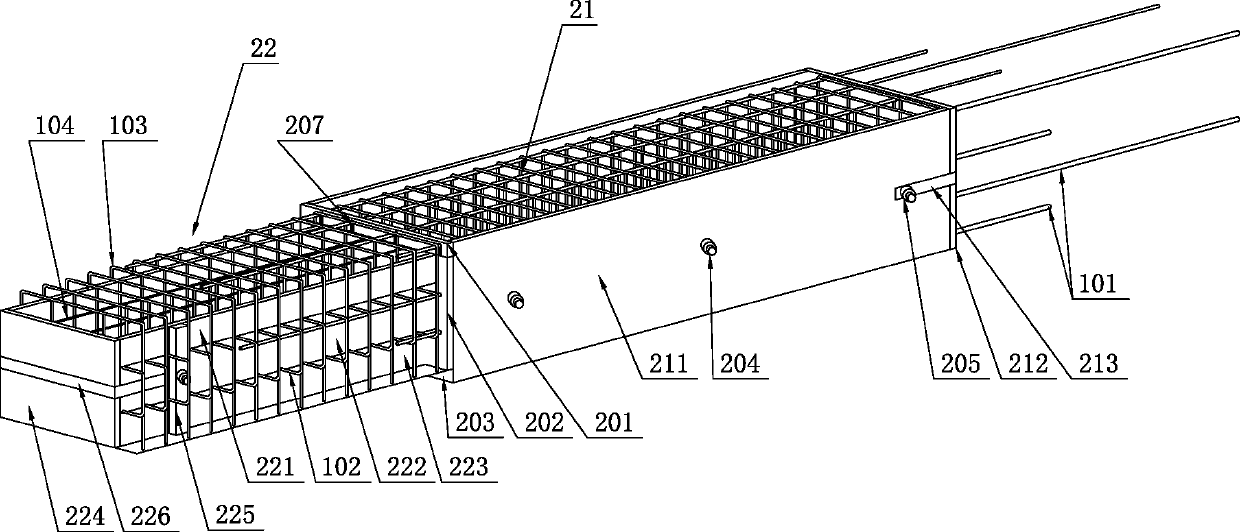

[0058] Such as figure 2 , image 3As shown, a manufacturing mold for a prefabricated reinforced concrete frame variable-section column described in Example 1 of the present invention, the mold includes a column upper section mold 21 and a core column mold 22, and is characterized in that: the column upper section mold 21 includes variable section upper baffle 201, variable section side baffle 202, variable section lower baffle 203, column upper section side template 211, column top outer baffle 212, column top outer baffle U-shaped hoop 213, outer mold tie rod 204 . Pull rod fastener 205, wherein, the column upper section side formwork 211 and the variable section side baffle 202 are two identical plates with left and right symmetry; the variable section upper baffle 201, the variable section side baffle 202, The lower baffle plate 203 with variable section, the side formwork 211 of the upper section of the column, the outer baffle plate 212 of the column top and the ground ...

Embodiment 3

[0060] Such as Figure 4 and Figure 5 As shown, a manufacturing mold for a prefabricated reinforced concrete frame variable-section column described in Example 1 of the present invention is based on Example 2, and several outer rails are vertically arranged along the main body width of the mold. The sleeve through-hole 2111 through which the pull rod 204 and the sleeve 208 penetrate, the sleeve through-hole 2111 runs through the upper side formwork 211 of the left and right columns or the upper formwork 221 of the core column, the middle formwork 222 of the core column, and the lower formwork 223 of the core column The casing 208 is installed in the through hole 2111 of the casing; the outer mold tie rod 204 is a pull screw, which passes through the casing 208, and after adding gaskets 2051 on both sides, fasten with corresponding supporting nuts 2052.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com