Bolt sleeve of wind power blade, blade root embedded part and production method of wind power blade

A technology for wind power blades and bolt sleeves, which is applied in the direction of threaded fasteners, nuts, connecting components, etc., can solve the problems of poor bonding force and changes of bolt sleeves, and achieve good cold and heat shock resistance, wide adaptability of blades, The effect of meeting complex load requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

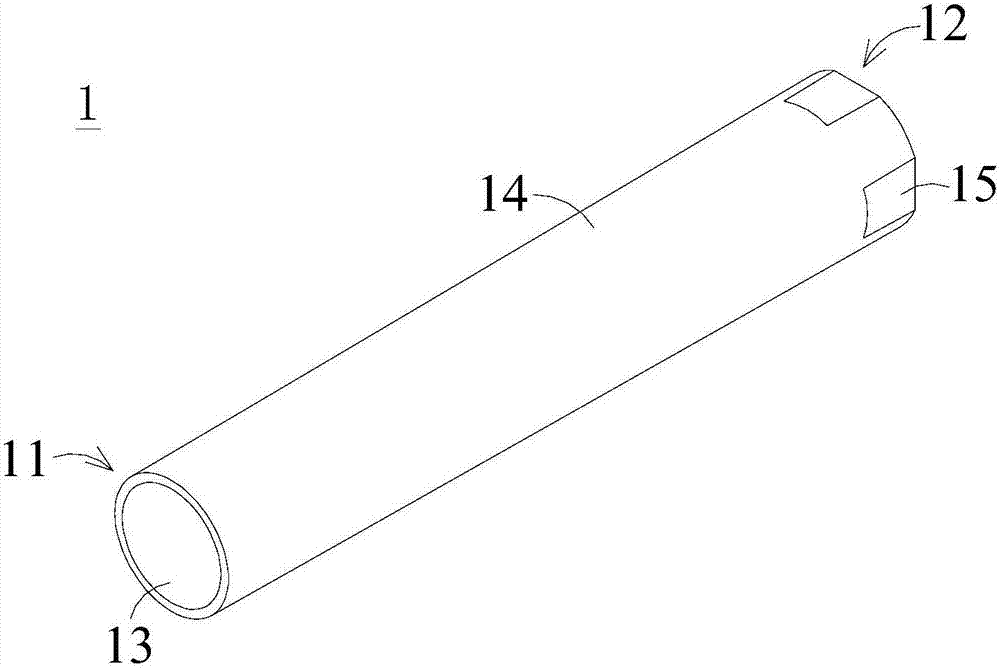

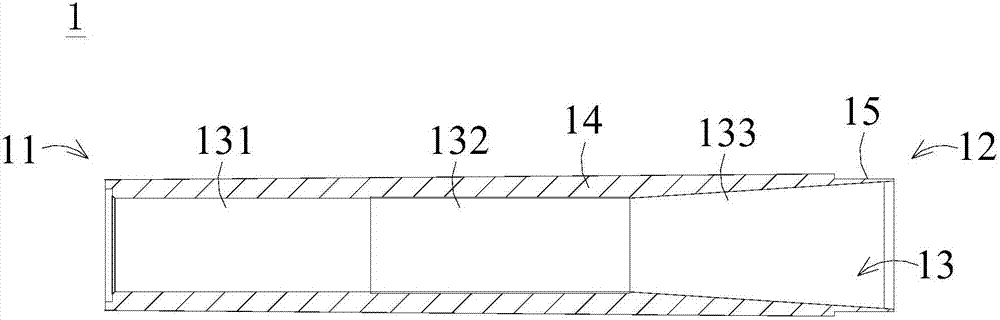

[0036] figure 1 It is a three-dimensional schematic diagram of the bolt sleeve structure of the wind turbine blade according to the first embodiment. figure 2 It is a schematic cross-sectional view of the bolt sleeve structure of the wind turbine blade according to the first embodiment.

[0037] As shown in the figure, the embodiment of the present invention provides a bolt sleeve 1 of a wind power blade, which can be pre-embedded in the blade root of the wind power blade, and a bolt rod can be screwed and fixed to the bolt sleeve 1, and then the bolt rod can be used to Connect with the outside. It can also be selected to be directly screwed and fixed with the external bolt shank. In order to use the bolt sleeve 1 to securely connect the wind turbine blade with the generating set.

[0038] In this exemplary embodiment, the bolt sleeve 1 can be cylindrical and long (the cylindrical shape is more suitable for lightweight design), and can include a first end 11 and a second e...

no. 2 example

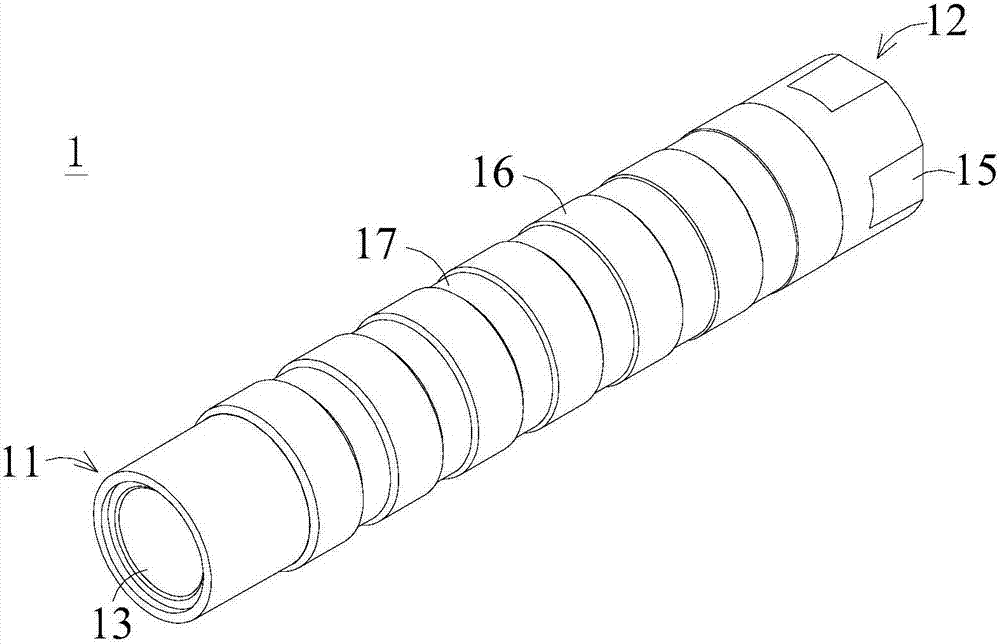

[0045] image 3 It is a three-dimensional schematic diagram of the bolt sleeve structure of the wind turbine blade according to the second embodiment. Figure 4 It is a schematic side view of the bolt sleeve structure of the wind turbine blade according to the second embodiment. Figure 5 It is a schematic cross-sectional view of the bolt sleeve structure of the wind turbine blade according to the second embodiment.

[0046] As shown in the figure, the bolt sleeve 1 of the second embodiment of the present invention can also be cylindrical and strip-shaped (cylindrical shape is more suitable for lightweight design), and can include a first end 11 and a second end 12 . The first end 11 is an end extending toward the root of the wind turbine blade, and the second end 12 is an end extending toward the tip of the wind turbine blade. The first end 11 can be exposed on the outer end surface of the blade root, the first end 11 can be selected to be flush with the end surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com