A three-dimensional memory electromigration test structure and its manufacturing method

A technology of test structure and manufacturing method, which is applied in the direction of semiconductor/solid-state device test/measurement, circuit, electrical components, etc., can solve the problems of test result deviation, test structure damage, etc., achieve fast and accurate positioning, realize precise positioning, and improve positioning the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

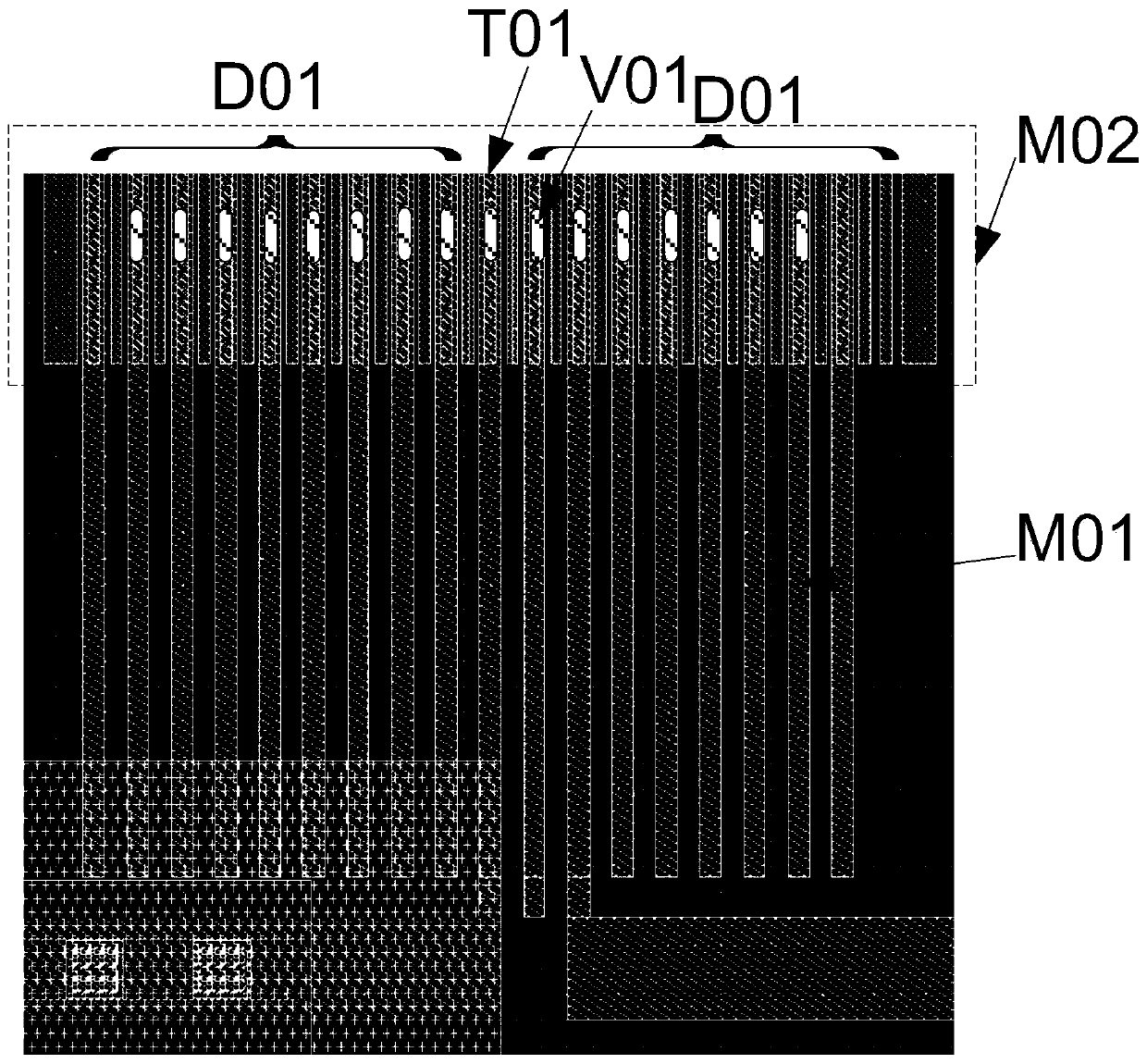

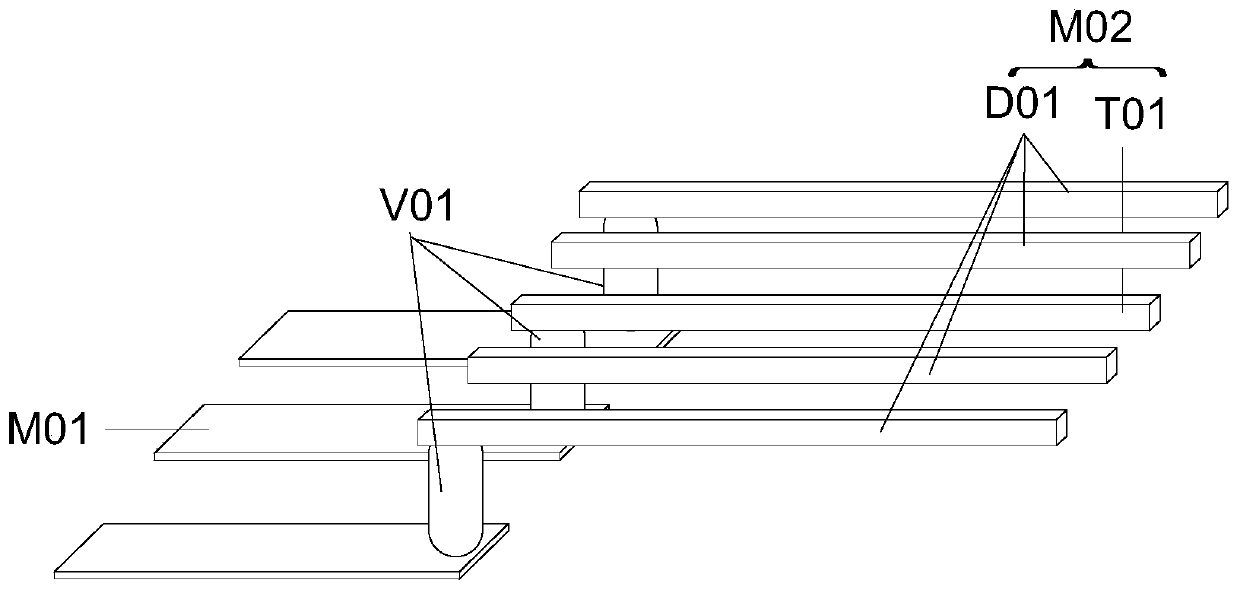

[0046] As mentioned in the background technology section, the positioning method of the test line in the prior art is easy to cause damage to the test structure, which in turn causes deviations in the test results during the test process.

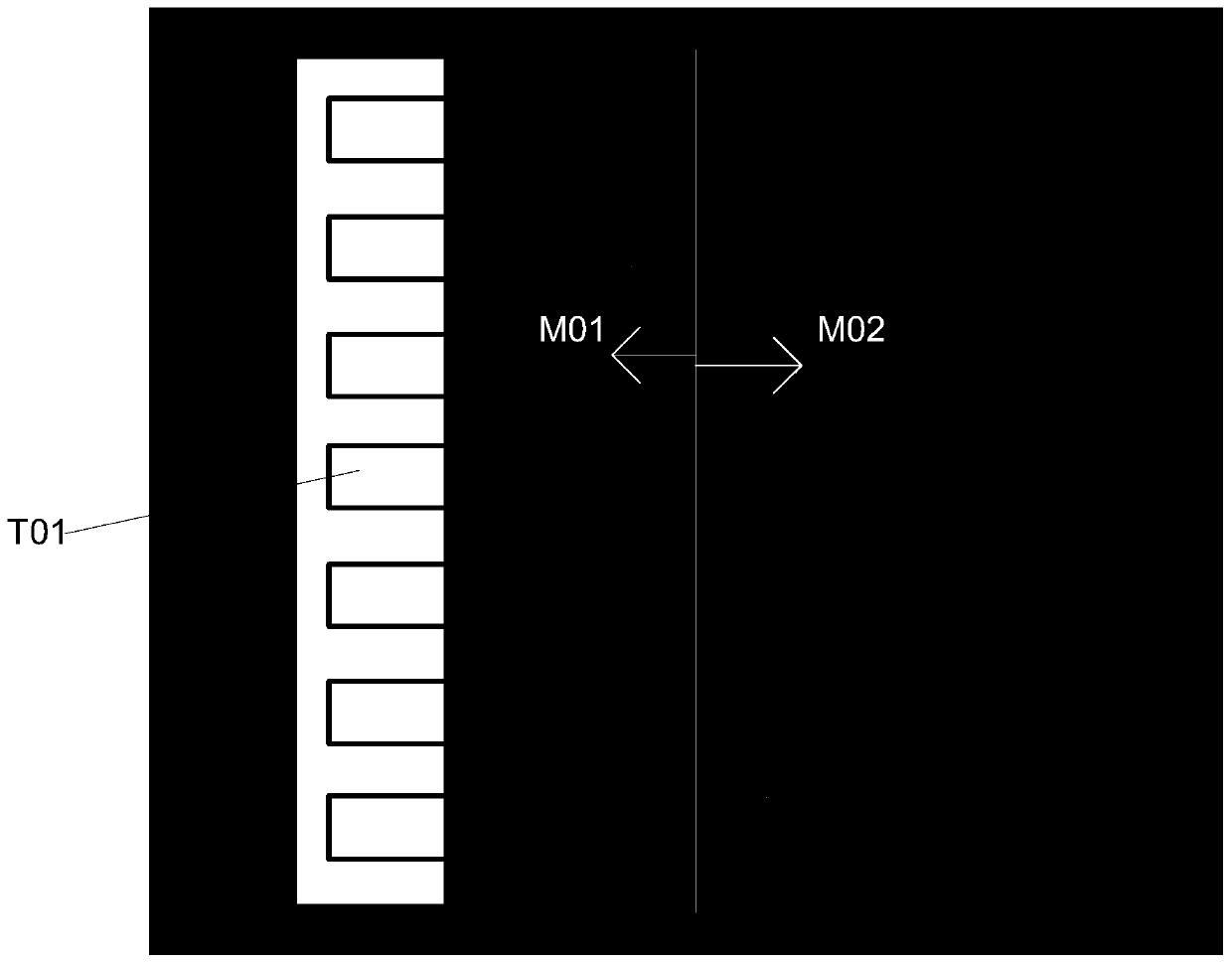

[0047]Specifically, since the main structure of the test line and the virtual line is the same, there is no big difference, so there is no way to locate the test line through the structural difference, and the test line must be located by setting a mark.

[0048] During the sample preparation process of the electromigration test structure, an oxide layer of tens of nanometers to a hundred nanometers must be reserved above the upper metal line M02 to avoid loss of the test line T01 in the M02 during the preparation of the FIB sample. Limited by the observation depth (<200nm) of SEM (Scanning Electron Microscope, scanning electron microscope), the thicker the oxide layer is, the less clear the image will be. Coupled with the fact that the wid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com