Power battery top cover component, power battery and battery module

A power battery and top cover technology, which is applied in the field of energy storage devices, can solve the problems of occupying the space of the module wiring harness board, the inability to use parallel connection of batteries, waste of materials, etc., and achieve the effect of optimizing the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

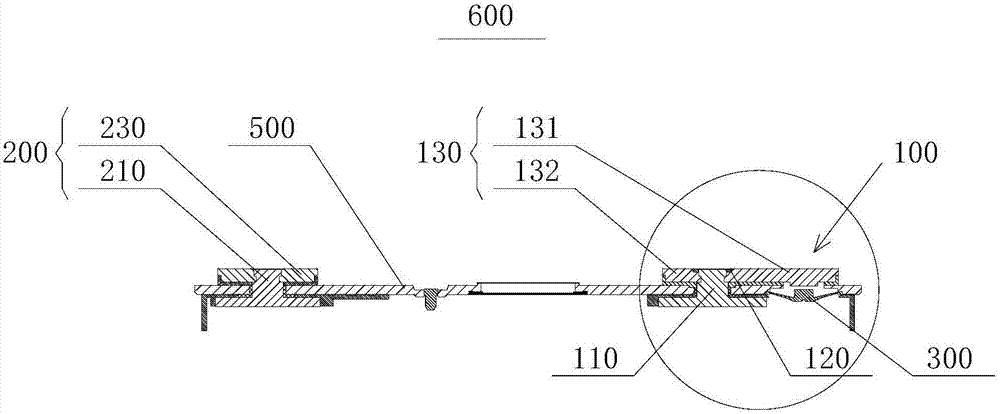

[0068] Such as figure 1 and Figure 6 As shown, according to the first aspect of the embodiment of the present invention, a power battery top cover assembly 700 is provided, including a top cover sheet 500, a first electrode terminal 100, and a second electrode terminal 200 (the first electrode terminal 100 may be a positive pole terminal, correspondingly, the second electrode terminal 200 is a negative terminal; the first electrode terminal 100 can also be a negative terminal, correspondingly, the second electrode terminal 200 is a positive terminal), wherein

[0069] The first electrode terminal 100 is installed at one end of the top cover sheet 500 along the length direction, and includes a first pole 110 and a first terminal board, and the first terminal board is located on one side of the top cover sheet 500 along the height direction and includes a first connecting board 130 and the first conductive plate 120, the first conductive plate 120 exposes the side of the firs...

Embodiment 2

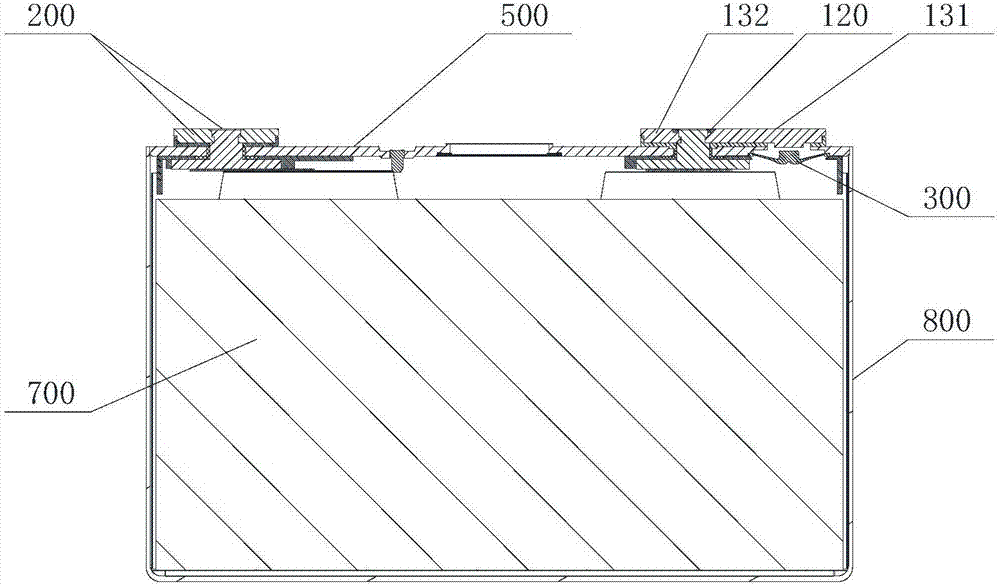

[0091] Such as Figure 2-3 As shown, according to the second aspect of the embodiment of the present invention, there is also provided a power battery 800, including: a battery cell 700, a casing and a power battery top cover assembly 600, wherein the casing accommodates the battery cell 700; the power battery top cover assembly 600; The cover assembly 600 closes the opening of the housing. The power battery top cover assembly uses the power battery top cover assembly 600 provided in Embodiment 1 to optimize the structure of the first electrode terminal, so that the connecting piece of a single material is connected with the first electrode terminal and the second electrode terminal. Good welding between the electrode terminals; battery top cover assembly In addition, when the power batteries are arranged in the thickness direction when the power batteries are connected in series, the first extension parts and the second electrode terminals of two adjacent power battery cells c...

Embodiment 3

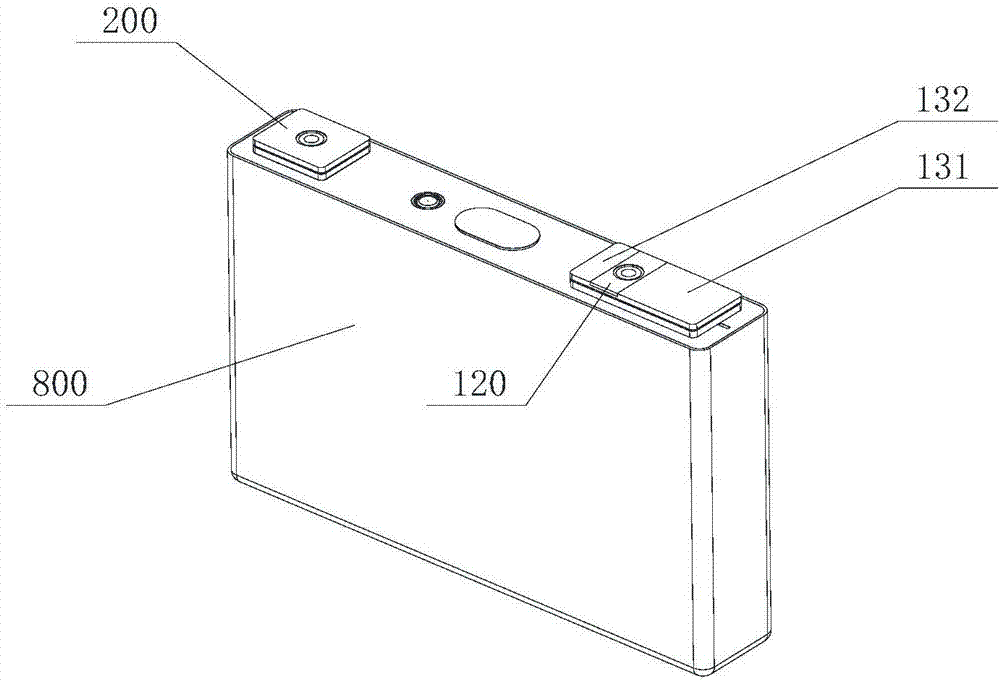

[0093] Such as Figure 4 As shown, according to the third aspect of the embodiment of the present invention, there is also provided a battery module, including: two or more power batteries 800, for the power battery 800, wherein the first connecting plate 130 of the first electrode terminal 100 is connected to the second The second terminal plate 230 of the two electrode terminals 200 adopts the same material; the electrode terminals of two adjacent power batteries 800 are connected through the connecting piece 801, the connecting piece 801 has the same material as the first connecting plate 130, and the connecting piece 801 is welded on the first extension 135 of one of the power batteries. The connection piece 801 extends along the width direction and is connected to the second electrode terminal 200 of another power battery 800 .

[0094] The battery module provided by the embodiment of the present invention optimizes the structure of the first electrode terminal in the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com