Device for real-time power feedback of high-power optical fiber laser

A fiber laser, real-time feedback technology, used in laser cooling devices, laser monitoring devices, lasers, etc., can solve problems such as thermal conductivity, poor adjustability, complex structure, etc., to achieve fast response speed, real-time feedback, and stable output. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

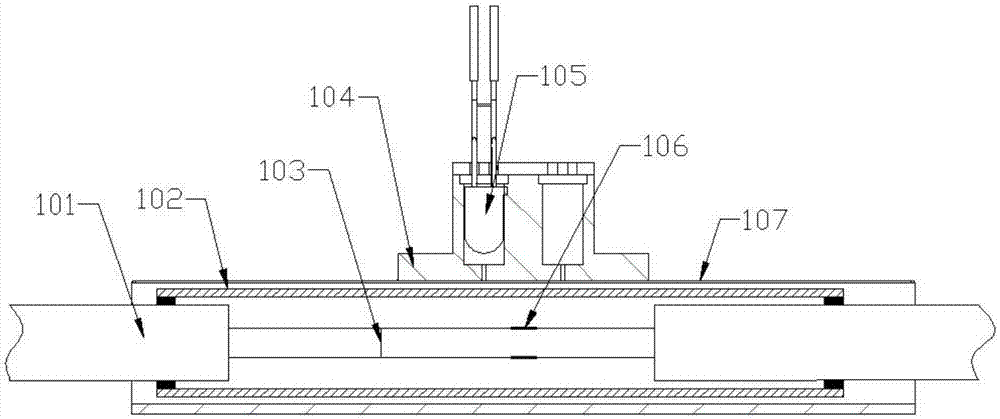

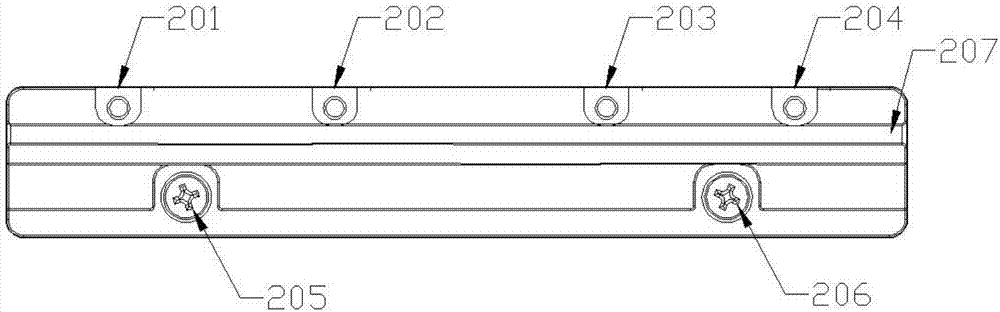

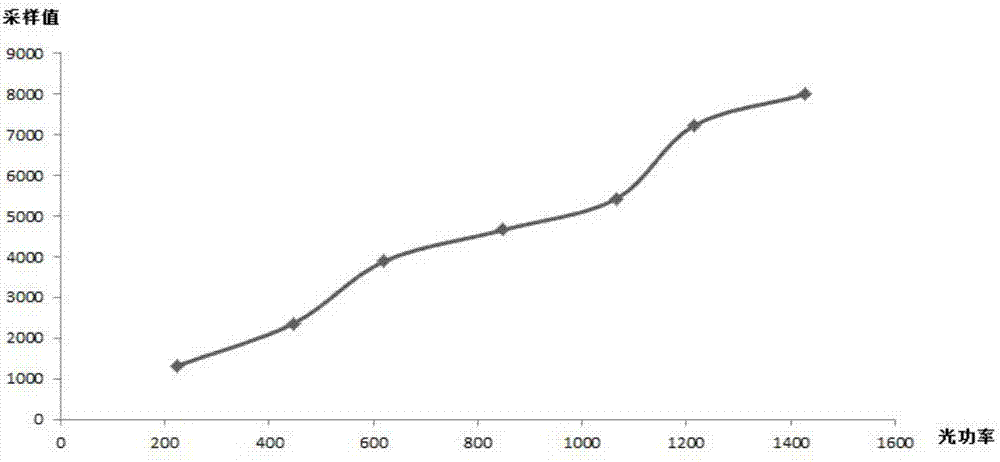

[0031] The laser uses 20 / 400 double-clad fiber as the output fiber, and the welding point between the stripper pigtail and the QBH is selected as the installation place of the device. The leaked cladding light will not be too strong, and will not cause serious heating and photoelectric detection. For the saturation of the device, corrode the inner cladding with hydrofluoric acid on the side of the fusion point, the corrosion length is about 2-3mm, cover the fusion point and the corrosion with a dehydroxylated glass tube with a length of about 2cm, and then use glue on both sides of the glass tube and fiber optics. Design a metal base, the external dimensions of the entire base can be designed to be 10cm×1.6cm, two fixing screws are fixed to the water cooling plate, there are fiber grooves, the width can be designed to be 2mm, four metal fixture installation positions are designed, kilowatt-level high-power full After the fiber laser passes through the cladding light stripper, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com