Mussel byssus removal machine

A kind of silk machine and mussel technology, which is applied in the field of mussel silk removal machine, can solve the problems of heavy workload, relying on labor, low work efficiency, etc., achieve strong corrosion resistance, improve comprehensive value, and prevent environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

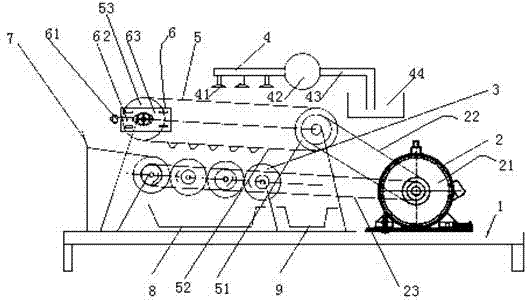

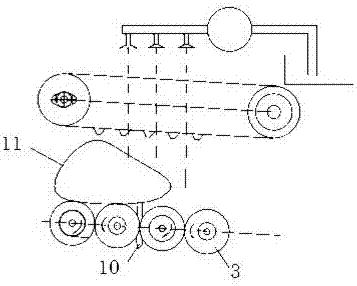

[0021] A mussel silk removal machine, comprising a frame 1, a power transmission system 2, a silk removal mechanism 3, a feeding mechanism 5, a tensioning device 6, a water spray system 4, a material opening 7, a waste collection box 8 and a collection box Material box 9.

[0022] Frame 1 is welded by profiles and plates to support other components.

[0023] The power transmission system 2 includes a motor 21 , a first power transmission component 23 and a second transmission component 22 , the motor 21 is arranged on the frame 1 , and both the first power transmission component 23 and the second transmission component 22 are belt pulley assemblies.

[0024] The thread removal mechanism 3 includes multiple groups of relative rolling rollers, which are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com