Processing method for mechanical heaping-yellowing of yellow tea

A processing method, the technology of stuffy yellow, applied in the direction of tea treatment before extraction, etc., can solve the problems of unfavorable influence on the quality stability of finished tea, high technical ability requirements of tea masters, etc., achieve convenient parameter adjustment and easy control, and improve quality stability , high aroma and sweet effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

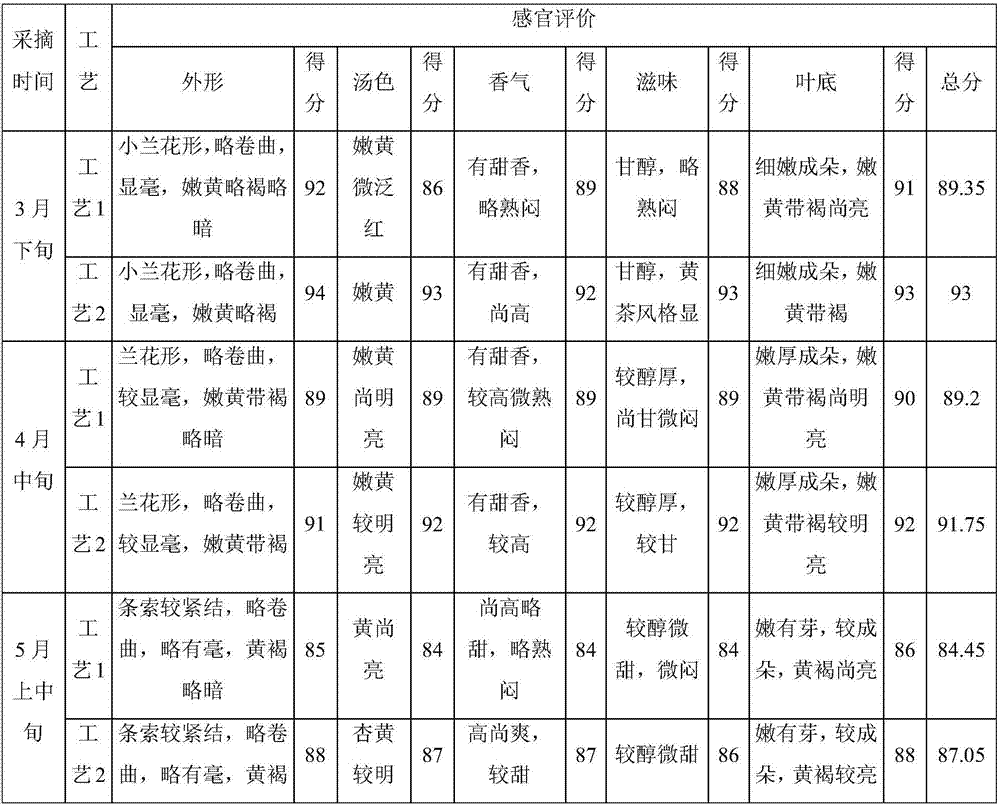

[0041] Example 1: Analysis of the influence of the "initial baking" process on the quality of finished yellow tea

[0042] The fresh leaves of Zhenong 113 picked in late March, mid-April, and early-to-mid May were evenly divided into two parts, and the yellow tea was processed by process 1 and process 2 respectively. The fresh leaves in late March were composed of: single bud 15%, one bud and one leaf 53%, one bud and two leaves 26%, one bud and three leaves 2%, single leaf 4%; the mechanical composition of fresh leaves in mid-April is: single bud 8.8%, one bud and one leaf 37.8%, 40% of one bud and two leaves, 7% of one bud and three leaves, and 6.4% of single leaf; the mechanical composition of fresh leaves in early and mid-May is: 4.5% of single bud, 27% of one bud and one leaf, 52% of one bud and two leaves, one bud Clover 10.5%, Single Leaf 6%.

[0043] Each process step is as follows respectively:

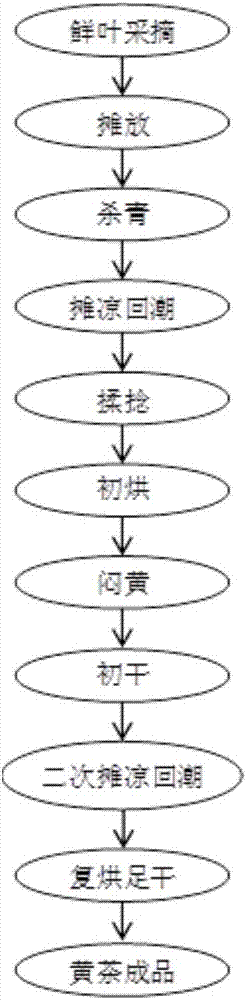

[0044] Process 1: ① Fresh leaves spread → ② Greening → ③ Cooling and r...

Embodiment 2

[0061] Example 2: Optimization of Technical Parameters of "Stuffy Yellow" Process

[0062] Pick the fresh leaves of Zhenong 113 in the middle and late April. The mechanical composition is as described in Example 1. The fresh leaves are evenly divided into several equal parts. Initial drying → ⑥ stuffy yellow → ⑦ initial drying → ⑧ secondary cooling and regaining moisture → ⑨ re-drying and full-drying process for yellow tea processing, in which the parameters of processes ①, ②, ③, ④, ⑤, ⑦, ⑧, ⑨ are in accordance with the implementation Set up as described in Example 1. The technical parameters of the ⑥ dull yellowing process are different in different processes, and the dull yellowing time is 8h. The prepared yellow tea also adopts the evaluation method stipulated in the national standard of "Tea Sensory Evaluation Method" (GB / T 23776-2009). The appearance, soup color, aroma, taste, and leaf bottom "five factors" are respectively described and scored for quality characteristic...

Embodiment 3

[0067] Embodiment 3: a specific implementation process utilizing optimal process flow and optimal process technical parameters, comprising the following steps:

[0068] ①Fresh leaf picking: pick Zhenong 113 fresh leaves in the middle and late April. The picking standard is one bud with two leaves to one bud with three leaves. The mechanical composition of fresh leaves is 8.8% for single bud, 37.8% for one bud and one leaf, and one bud for two leaves 40%, one bud three leaves 7%, single leaf 6.4%.

[0069] ② Spreading: Spread the fresh leaves evenly in the withering trough with a thickness of about 3cm, and let them stand naturally for 14 hours, during which time there will be assisted blowing twice, until the moisture content of the fresh leaves is about 67%, and the leaf shape will shrink slightly. The stems and leaves are soft and not easy to break.

[0070] ③Finishing: Use 6CST-50 type roller fixing machine, set the heat source temperature to 300°C, and the actual temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com