Silicon carbide micro-channel reactor and application thereof in preparing low carbon olefin from hydrocarbons cracking

A micro-channel reactor, the technology of the reactor, which is applied in the fields of hydrocarbon cracking to produce hydrocarbons, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as potential safety hazards, overheating, and large pressure drop.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

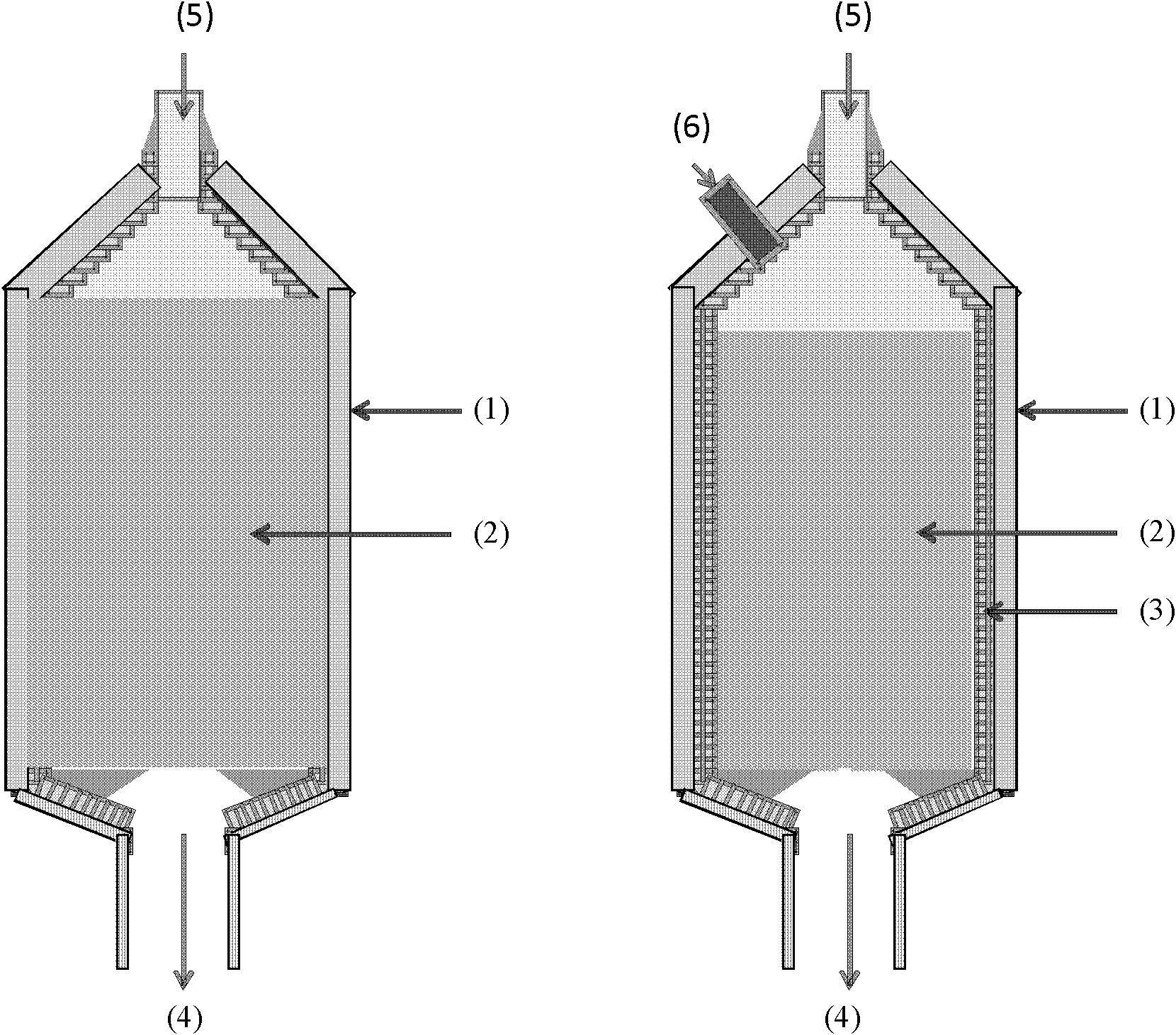

Image

Examples

Embodiment 1

[0015] The upper end of the reactor is equipped with a material inlet and the lower end is equipped with a material outlet. It adopts a circular stainless steel shell with a quartz coating on the inner wall; the diameter of the circular inner cavity of the reactor is 20mm, and it is filled with two circular foam carbonization The silicon is closely combined to form an overall structure with a diameter of 20mm, a total height of 40mm, and a foam channel diameter of 0.5mm, which is encapsulated in a reactor with a quartz layer inside.

[0016] The silicon carbide microchannel reactor is used for cracking hydrocarbons to produce low-carbon olefins, which can strengthen the mixing of reaction materials, reduce the temperature difference in the reactor, and increase the cracking activity of hydrocarbons.

[0017] The reactor is used for cyclohexane oxidative cracking reaction. Compared with the reactor not filled with silicon carbide, the conversion rate of cyclohexane increased by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com