Leaching waste gas treatment tower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below by means of specific embodiments:

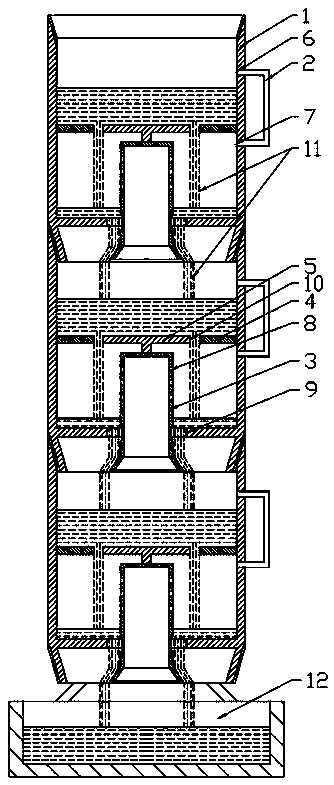

[0019] The reference signs in the drawings of the description include: shell 1, conduit 2, air pipe 3, baffle ring 4, baffle plate 5, air inlet hole 6, air outlet hole 7, air diffuser hole 8, discharge hole 9, flow gap 10 , water curtain 11, recovery pond 12.

[0020] Example leaching exhaust gas treatment tower is basically as attached figure 1 As shown: it includes several processing units stacked up and down. The processing unit includes a conduit 2 and a cylindrical shell 1. The upper end of the shell 1 is open and the lower end is closed. The outer diameter of the lower end of the shell 1 is smaller than the inner diameter of the upper end. There are external threads, and the inner wall at the top of the casing 1 is provided with internal threads that match the external threads. The bottom surface of the casing 1 is equipped with a gas pipe 3, which is parallel to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com