Chemical material reaction device

A technology of reaction device and chemical raw material, applied in the field of chemical raw material reaction device, can solve the problems of affecting work efficiency, increasing reaction cost, wasting time, etc., and achieving the effects of reducing the use of manpower, improving the reaction speed, and reducing the loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

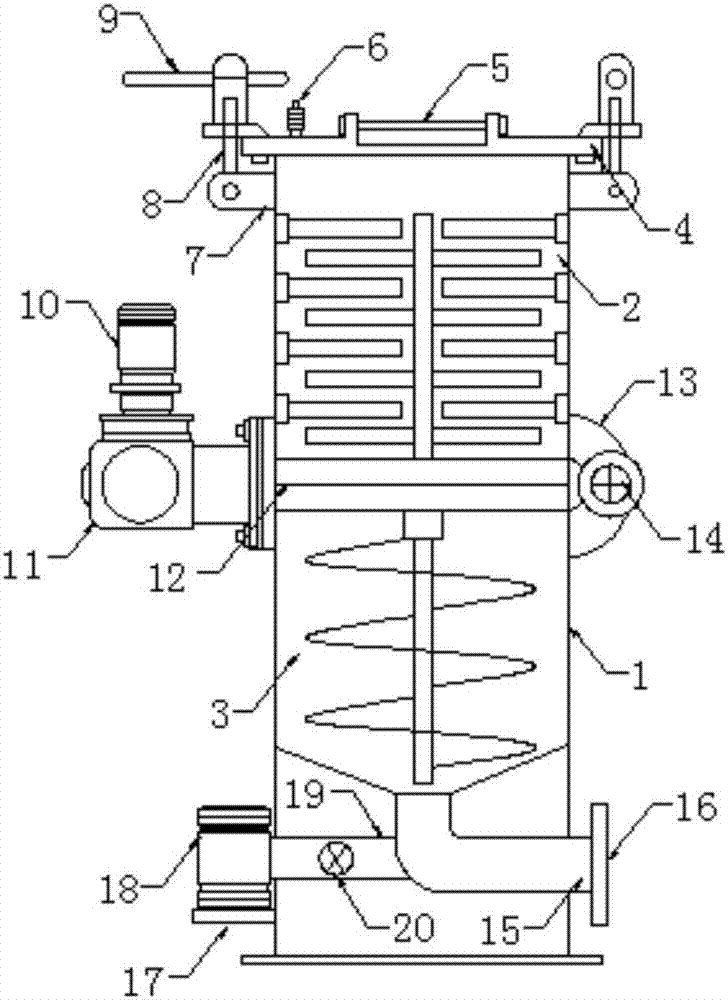

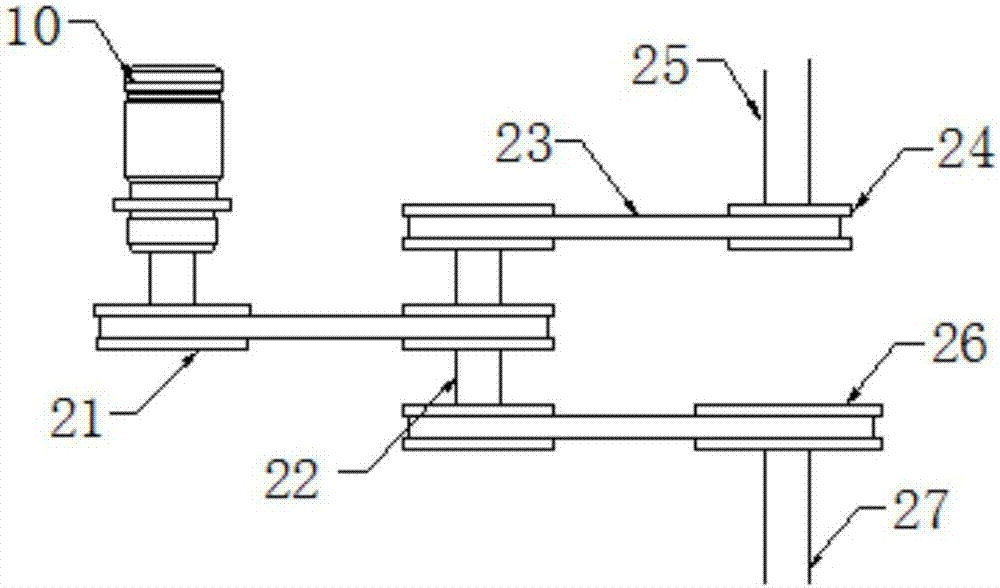

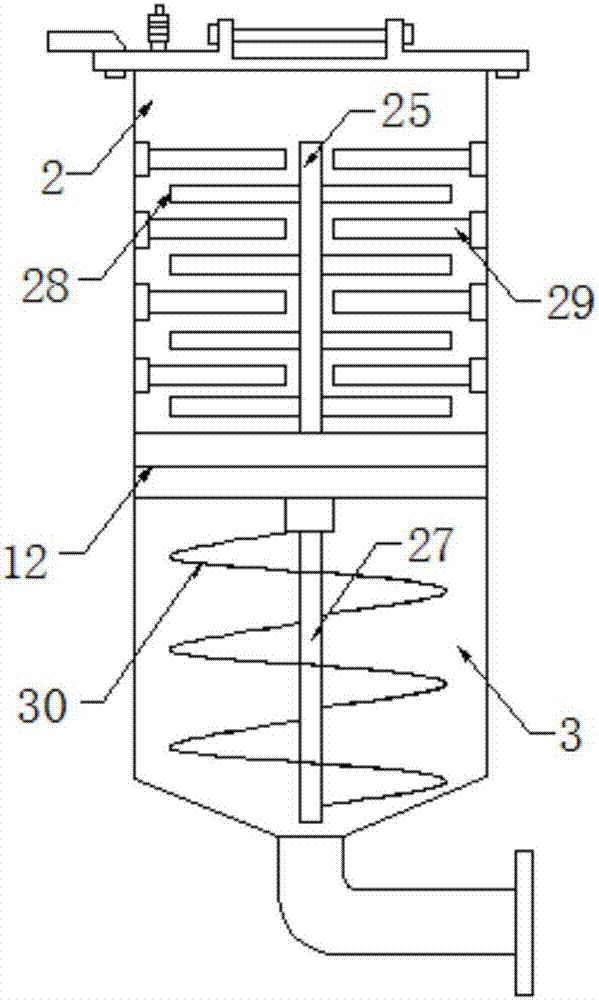

[0021] Such as Figure 1-3 As shown, this specific embodiment adopts the following technical solutions: a chemical raw material reaction device, including a cylinder body 1, a crushing chamber 2, a mixing chamber 3, an upper cover 4, a handle 5, a pressure valve 6, an ear plate 7, and a positioning pin 8. Locking knob 9, drive motor 10, motor base 11, spindle box 12, material delivery pipe 13, gate valve 14, discharge pipe 15, discharge port 16, fan seat 17, blower 18, air delivery pipe 19, air volume Regulating valve 20, driving wheel 21, main shaft 22, transmission belt 23, first driven wheel 24, crushing shaft 25, second driven wheel 26, mixing shaft 27, movable tooth block 28, fixed tooth block 29 and mixing blade 30, The cylinder body 1 includes a crushing chamber 2 and a mixing chamber 3, an upper cover 4 is installed at the top of the cylinder body 1, an ear plate 7 is fixed on the side wall of the top end of the cylinder body 1, and the end of the upper cover 4 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com