Solid catalyst, preparation method and applications thereof

A technology of solid catalysts and substrates, applied in chemical instruments and methods, chemical elements of heterogeneous catalysts, physical/chemical process catalysts, etc., can solve problems such as shedding, reduced activity, and difficulty in coating nano-powders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

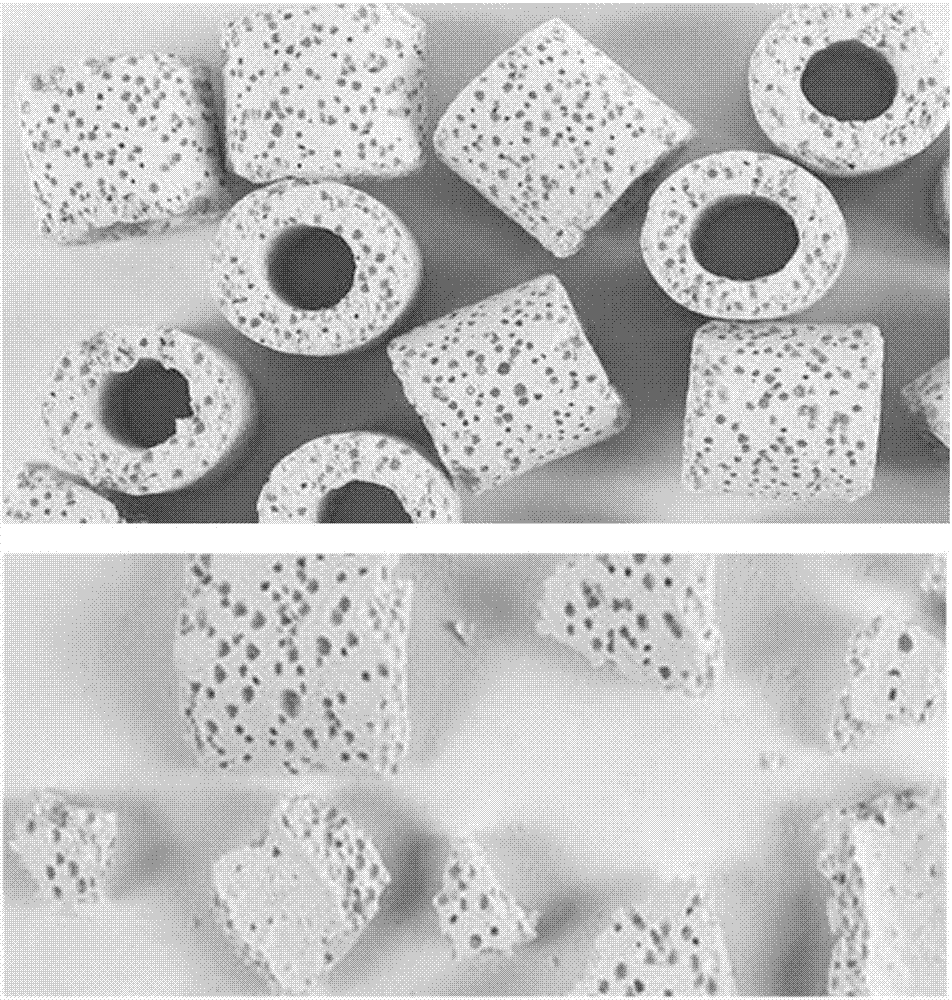

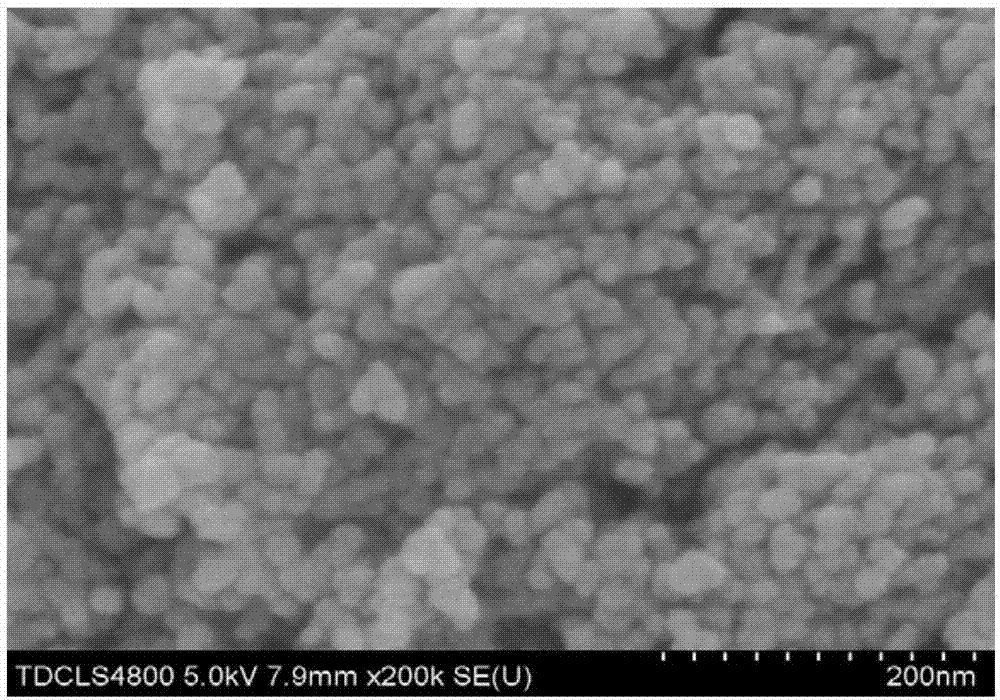

[0108] Embodiment 1, a kind of solid catalyst, it is characterized in that: be coated with transition metal nano-oxide on the porous ceramic substrate, the nano particle distribution of its coating is uniform, and diameter is lower than 50nm on average, and does not agglomerate, is evenly coated on The surface and interior of porous ceramic substrates.

Embodiment 2

[0109] Embodiment 2, a kind of solid catalyst as described in embodiment 1, is characterized in that:

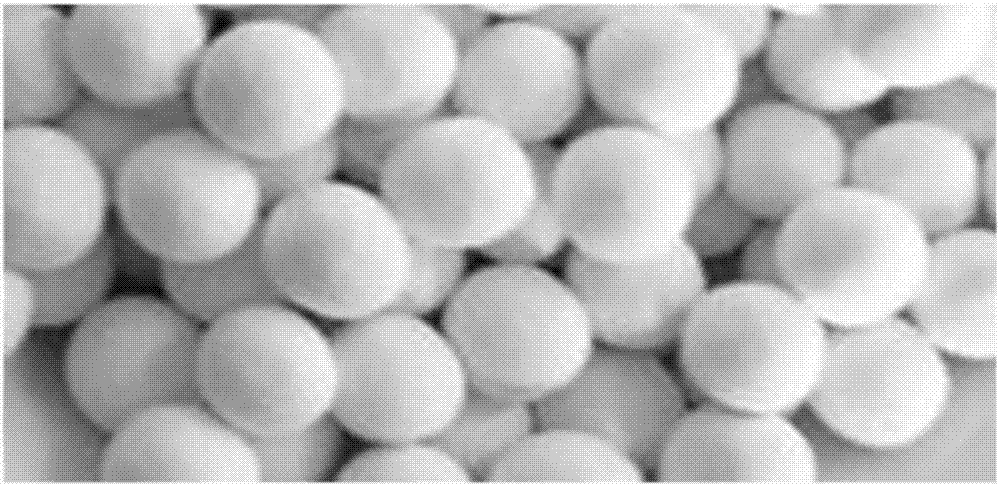

[0110] The porous ceramic matrix is respiratory ring fragments or ceramic balls, and the specific surface area is greater than or equal to 1 square meter per gram.

Embodiment 3

[0111] Embodiment 3, a solid catalyst as described in Embodiment 1, is characterized in that: it can be used stably in the environment where the flow rate of gas or liquid is 0 to 6 meters per second.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com