A kind of color-changing air-purifying dry powder coating and its preparation method and application

A technology of air purification and dry powder coating, applied in the field of coatings, can solve the problems of indoor comfort adjustment and artistic conception adjustment, and achieve the effect of good indoor comfort and artistic conception adjustment and good air purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

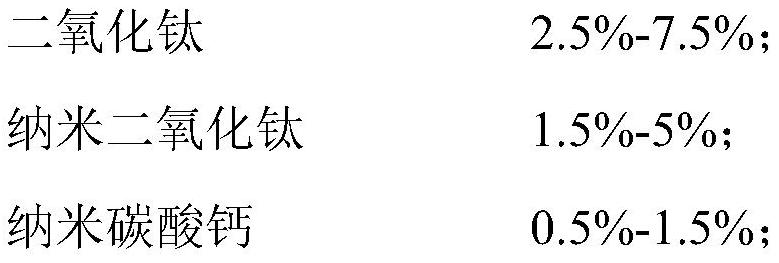

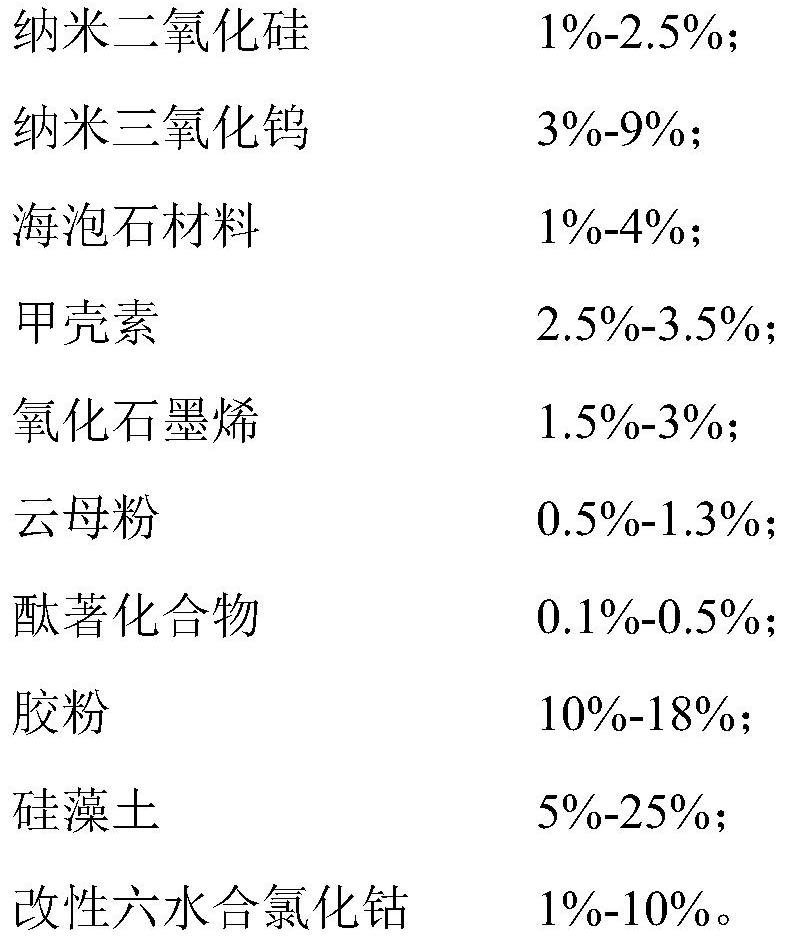

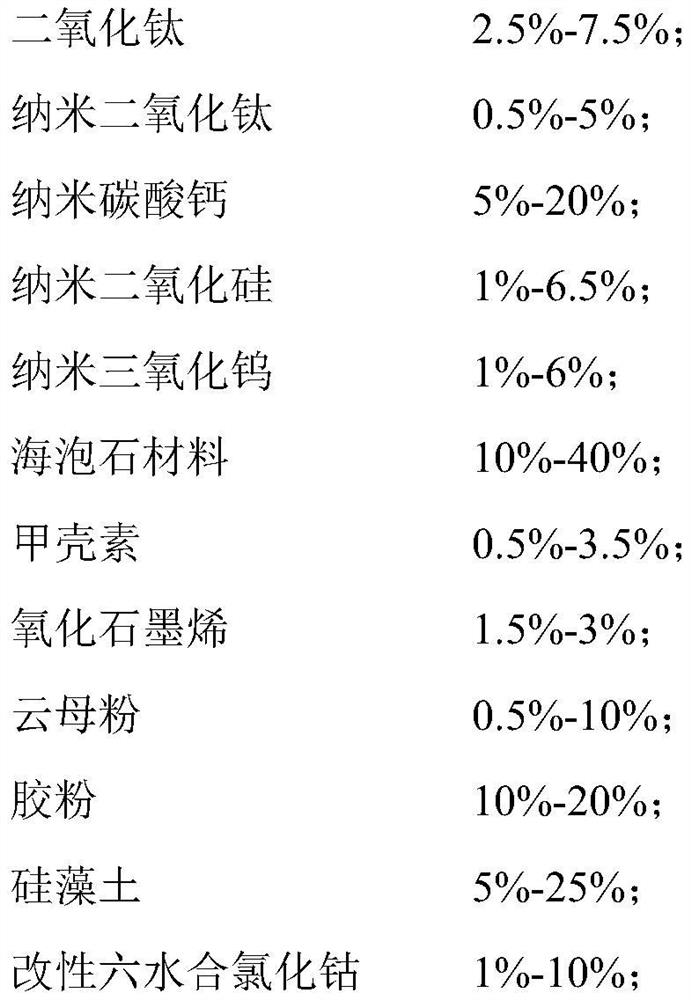

Method used

Image

Examples

Embodiment 1

[0030] A kind of color-changing air-purifying dry powder coating of the embodiment of the present invention, the raw material composition of this color-changing air-purifying dry powder coating is as follows (percentage by weight): titanium dioxide 2.5%, nanometer titanium dioxide 0.5%, nanometer calcium carbonate 20%, nanometer calcium dioxide Silicon 1.5%, nano-tungsten trioxide 1%, sepiolite material 15%, chitin 3%, graphene oxide 2.5%, mica powder 10%, rubber powder 20%, diatomite 19%, modified chlorine hexahydrate Cobalt 5%. Wherein, the particle size of nano-titanium dioxide used is 4-10nm; the particle size of nano-tungsten trioxide used is 2-6nm; the particle size of titanium dioxide used is more than 50nm; the particle size of diatomaceous earth used is 200-800 mesh.

[0031] The preparation method of the color-changing air-purifying dry powder coating is as follows: add diatomite and modified cobalt chloride hexahydrate into a mixer according to the proportion and mi...

Embodiment 2

[0039] A kind of color-changing air-purifying dry powder coating of the embodiment of the present invention, the raw material composition of this color-changing air-purifying dry powder coating is as follows (percentage by weight): titanium dioxide 5%, nanometer titanium dioxide 2%, nanometer calcium carbonate 16%, nanometer calcium dioxide Silicon 3%, nano-tungsten trioxide 2%, sepiolite material 25%, chitin 1%, graphene oxide 2%, mica powder 5%, rubber powder 15%, diatomite 17%, modified chlorine hexahydrate Cobalt 7%. Wherein, the particle size of nano-titanium dioxide used is 4-10nm; the particle size of nano-tungsten trioxide used is 2-6nm; the particle size of titanium dioxide used is more than 50nm; the particle size of diatomaceous earth used is 200-800 mesh.

[0040] The preparation method of the color-changing air-purifying dry powder coating is as follows: add diatomite and modified cobalt chloride hexahydrate into a mixer according to the proportion and mix evenly,...

Embodiment 3

[0044] A kind of color-changing air-purifying dry powder coating of the embodiment of the present invention, the raw material composition of this color-changing air-purifying dry powder coating is as follows (percentage by weight): titanium dioxide 6.5%, nanometer titanium dioxide 5%, nanometer calcium carbonate 10%, nanometer dioxide Silicon 5%, nano-tungsten trioxide 5%, sepiolite material 30%, chitin 1%, graphene oxide 1.5%, mica powder 3%, rubber powder 12%, diatomite 12%, modified chlorine hexahydrate Cobalt 9%. Wherein, the particle size of nano-titanium dioxide used is 4-10nm; the particle size of nano-tungsten trioxide used is 2-6nm; the particle size of titanium dioxide used is more than 50nm; the particle size of diatomaceous earth used is 200-800 mesh.

[0045] The preparation method of the air-purifying dry powder coating is as follows: adding diatomite and modified cobalt chloride hexahydrate into a mixer according to the proportion and mixing evenly, and then add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com