Testing method for bubble-particle adhesion collision behavior in coal slime flotation

A test method and technology of coal particles, applied in flotation, particle and sedimentation analysis, measuring devices, etc., can solve problems such as difficulty, lack of field practicability, and complicated flotation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be further described below.

[0026] Aiming at the existing coal slime flotation process, the present invention proposes a test method for the adhesion and collision behavior of bubble particles in coal slime flotation, which provides a basis for the coal slime flotation production process in coal preparation plants, so as to achieve reasonable flotation by changing The purpose of controlling and reducing the entry of inorganic minerals into clean coal has great guiding significance for further improving the yield and grade of clean coal.

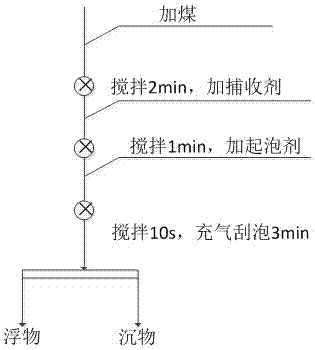

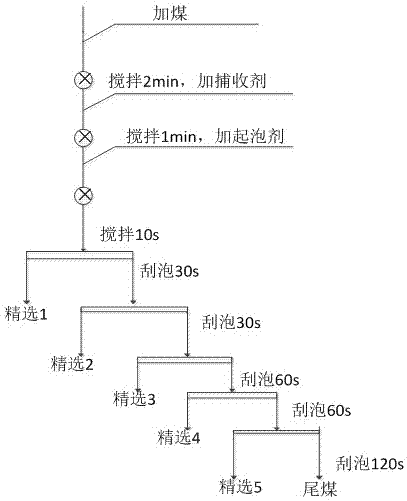

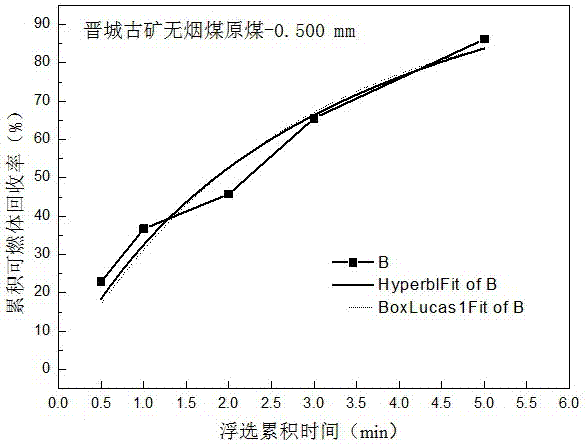

[0027] First of all, the flotation speed test is carried out on the collected slime samples from the site, and the actual content of inorganic minerals and clean coal in the clean coal products in each stage of flotation are obtained through calculation, and the effective viscosity of air bubbles-coal particles is further calculated. Then, the cumulative recovery rate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com