A metal wire drawing cutting system

A metal wire and wire drawing technology, used in metal wire drawing, metal processing equipment, conveying filamentous materials, etc., to achieve the effect of reasonable structure design, space saving and compact connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

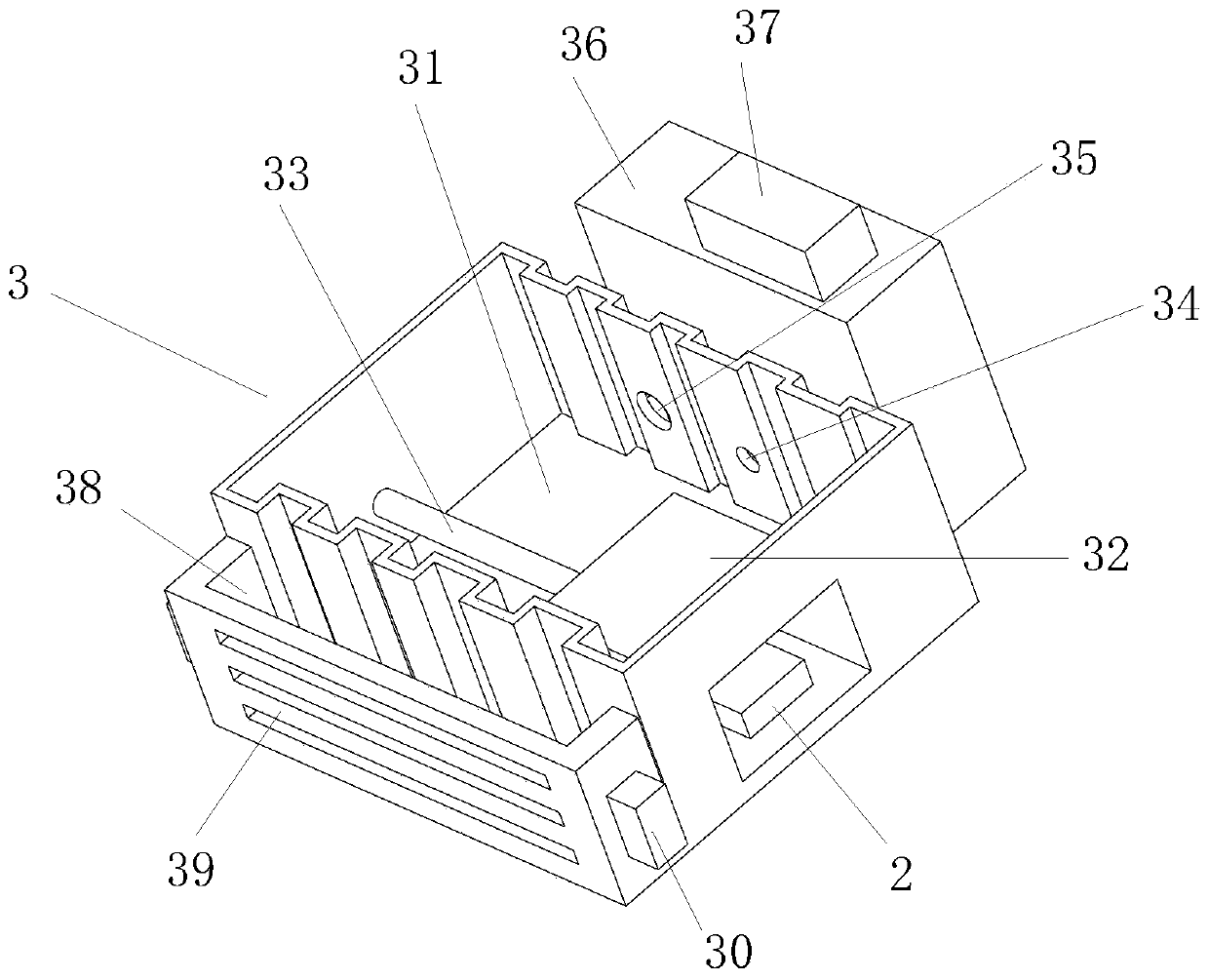

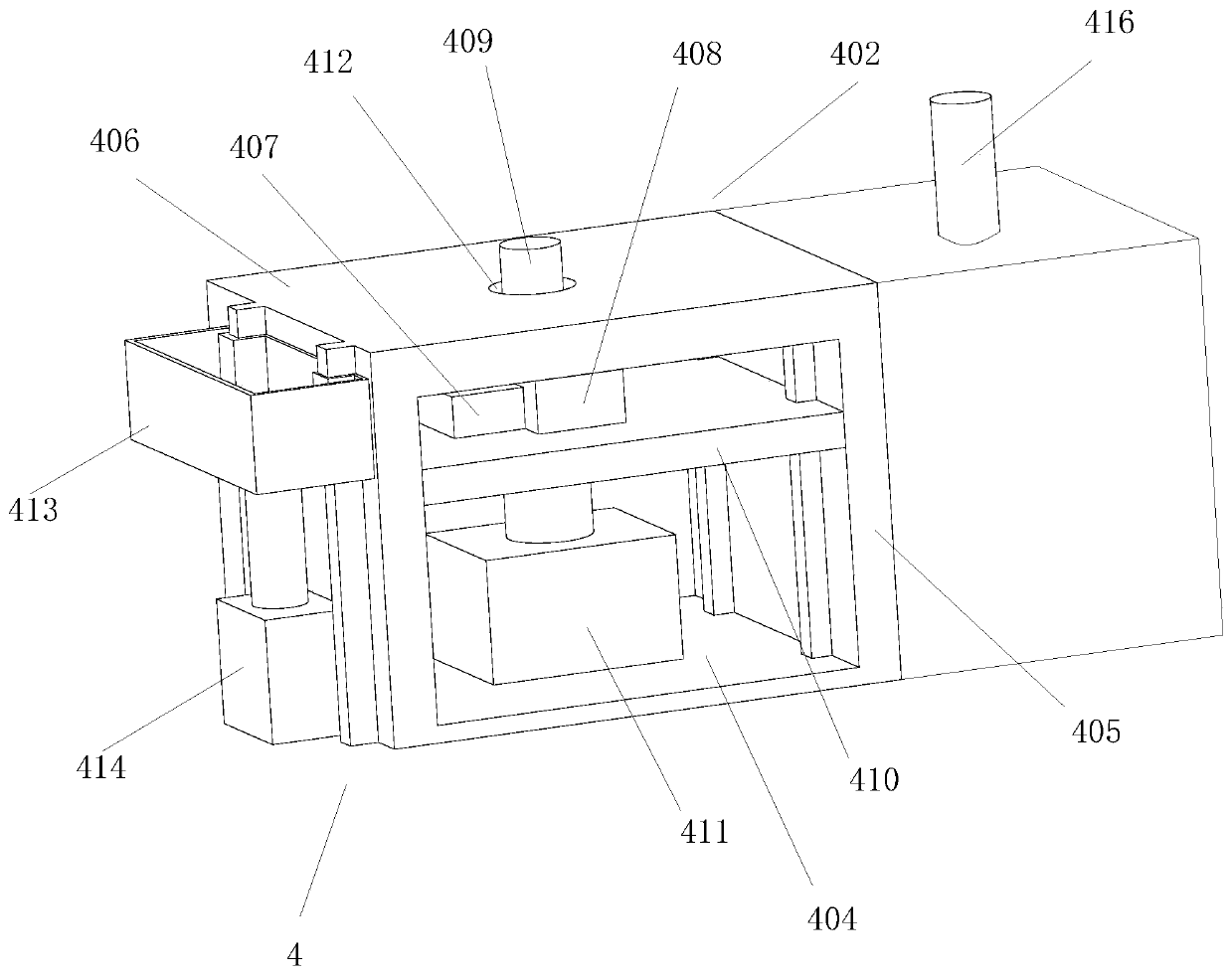

[0038] Such as Figure 1 to Figure 12 As shown, a metal wire drawing cutting system includes a wire drawing system and a cutting system. The wire drawing system includes an upper line device 1, a wire drawing device 2, a cooling device 3 and a wire coiling device 4. The cutting system includes a straightening mechanism 5, a wire holding The transportation device 6 and the metal wire cutting and collecting device 7; the traveling route of the metal wire is divided into two sections, the first section is the on-line device 1, the wire drawing device 2, the cooling device 3 and the coiling device 4; Device 4, straightening mechanism 5, wire holding and transporting device 6 and wire cutting and collecting device 7;

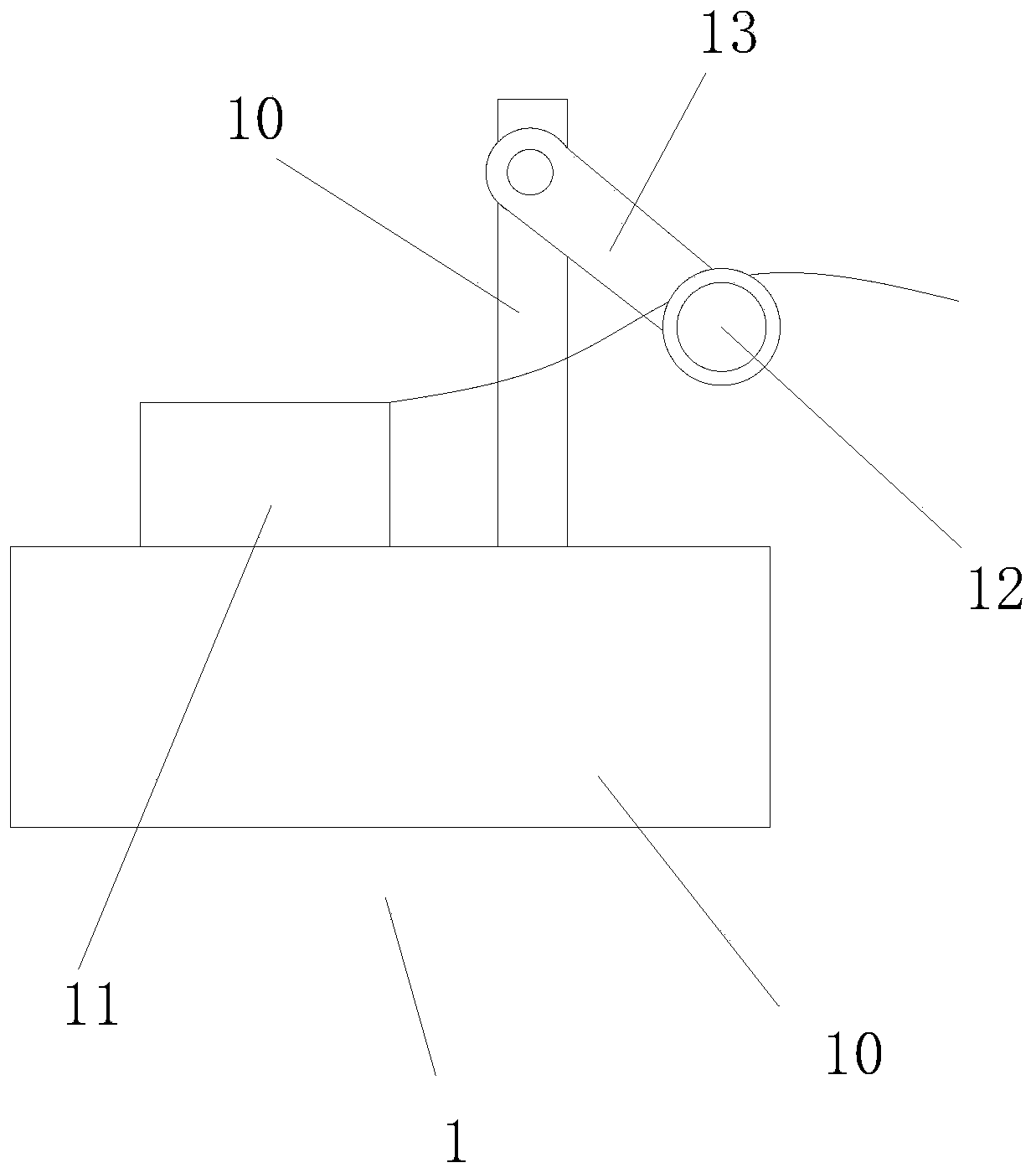

[0039] On-line device 1 comprises on-line frame 10, and on-line frame 10 is provided with the holding dish 11 of holding metal wire and is used for the primary guide wheel 12 of wire primary guidance, and on-line frame 10 is provided with fixed bar 13, and fixed bar ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com