Gear shaper cutter free of theoretical edge shape errors

A technology of gear shaping cutter and blade shape, which is applied in the direction of gear teeth, components with teeth, gear tooth manufacturing tools, etc., can solve the problems of poor consistency of machining accuracy and theoretical edge shape error, and achieve good consistency of machining accuracy, The effect of high tool strength and improved cutting conditions for gear shaping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention will be described in detail below with reference to the drawings and specific implementations.

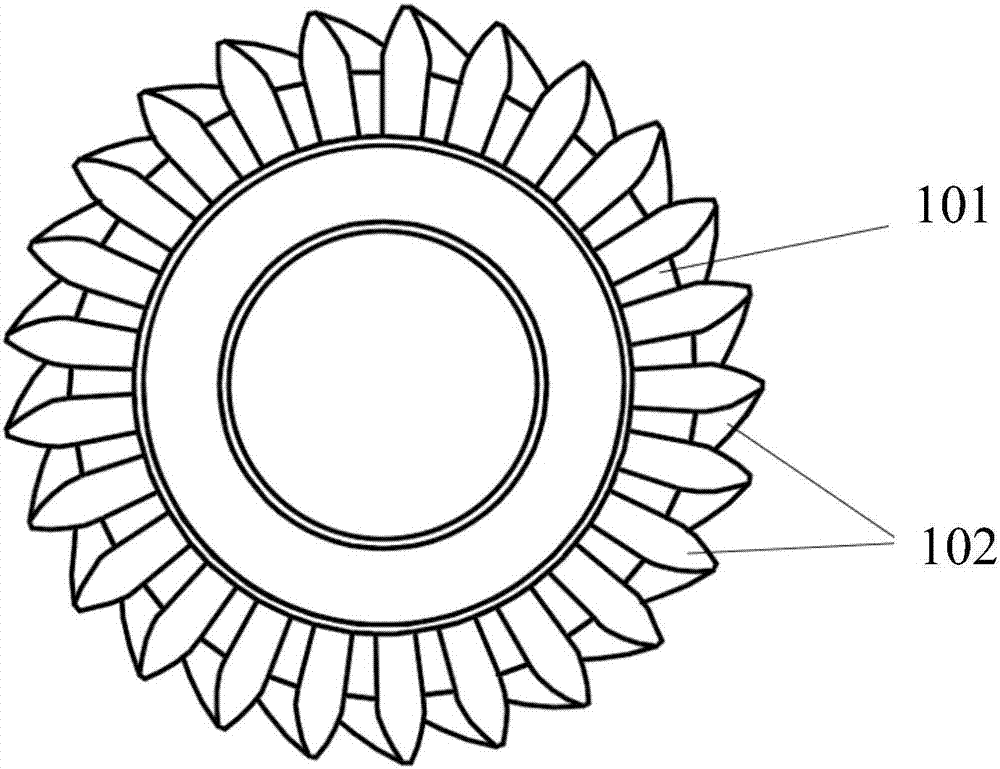

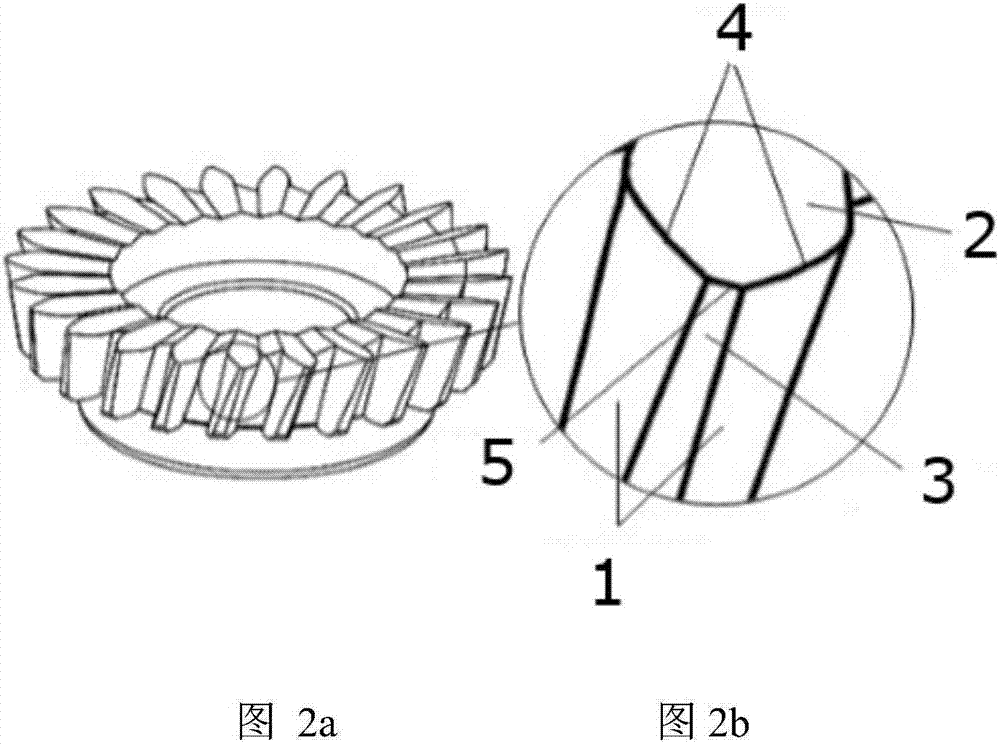

[0019] Such as Figure 1~2 As shown, a gear shaper cutter with no theoretical edge error includes a cutter body 101 and cutter teeth 102 distributed circumferentially on the cutter body; each individual cutter tooth 102 has a left-right symmetrical structure, and has a side relief surface 1, Rake face 2, top relief face 3, side edge 4 and top edge 5;

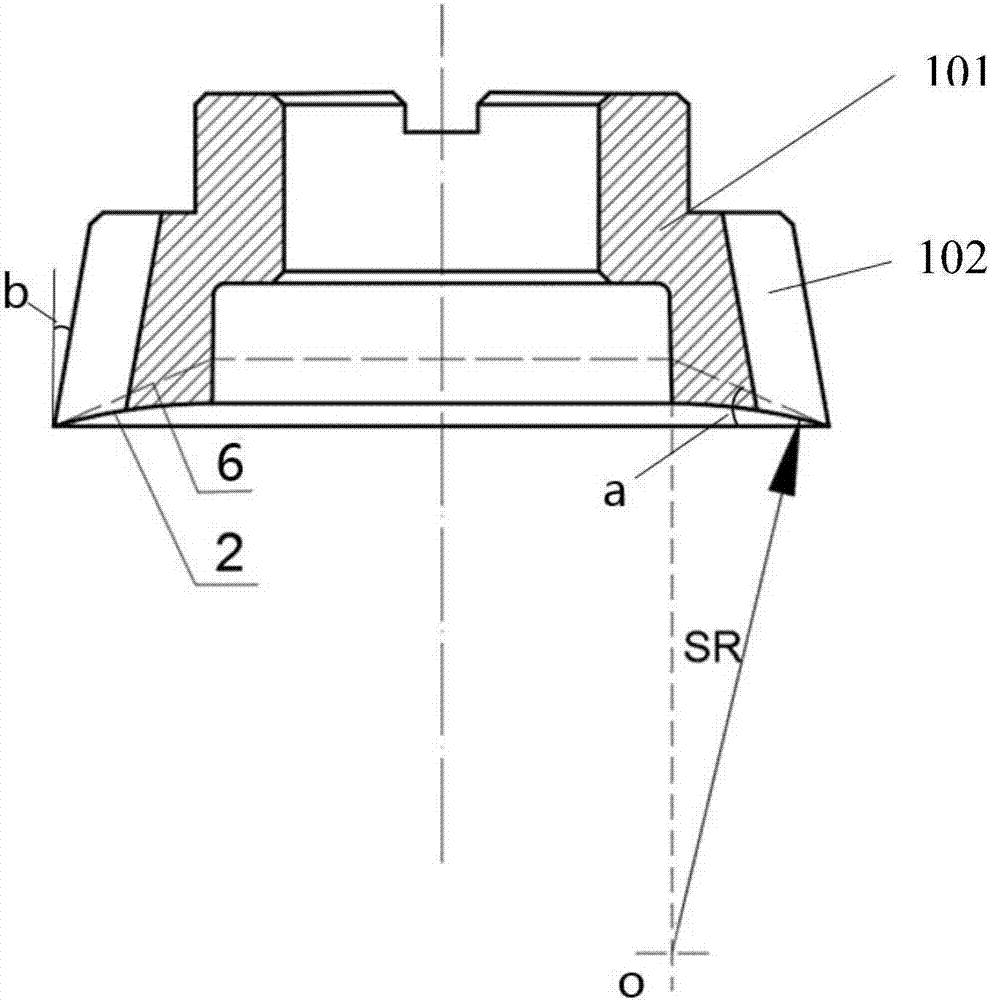

[0020] Such as image 3 As shown, the top edge rake angle a is 6-20°, and the top edge relief angle b is 7-10°. Preferably, the top edge rake angle a is 15°, and the top edge back angle b is 9°.

[0021] Construct a spherical surface according to the above-mentioned top edge rake angle to form rake face 2; determine the diameter of the tool tip circle according to the parameters of the gear to be processed, and on this basis, construct a conical surface according to the above-mentione...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com