Fully-automatic nut welding system for production of special-shape heating tube assembly line

A welding system and assembly line technology, applied in the direction of welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of small heating pipe flange space, time-consuming and labor-intensive, high cost, etc., to save costs, save manpower, structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

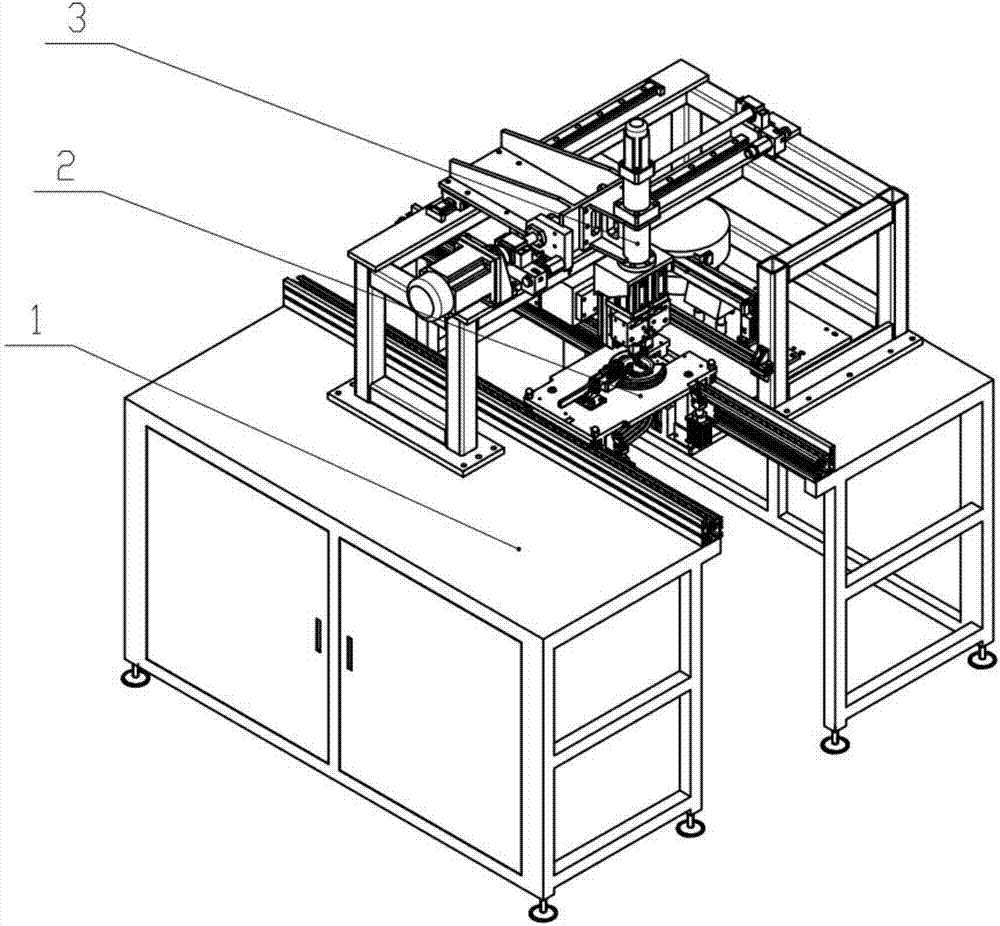

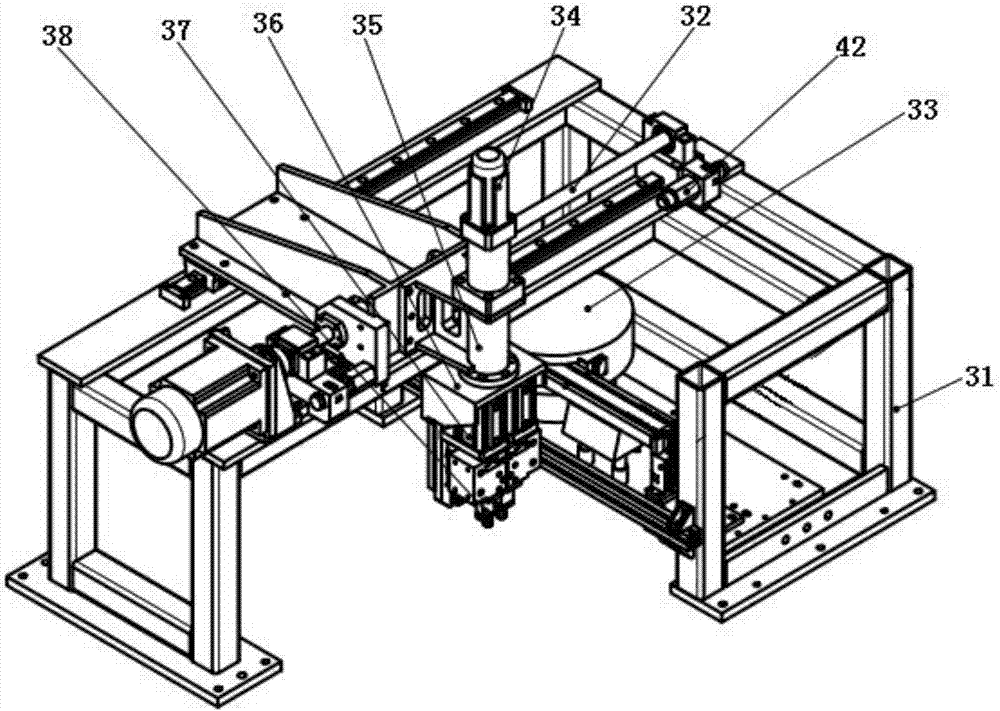

[0030] Such as Figure 1 to Figure 6 As shown, a fully automatic nut welding system for special-shaped heating tube production line, including:

[0031] The double-speed chain 1 is used to transport the clamped special-shaped heating tube to the nut welding station. Place the clamped special-shaped heating tube on the double-speed chain 1, carry out mobile transportation and realize positioning at a specific position, and complete the welding of the special-shaped heating tube and the nut at the positioning position of the double-speed chain 1.

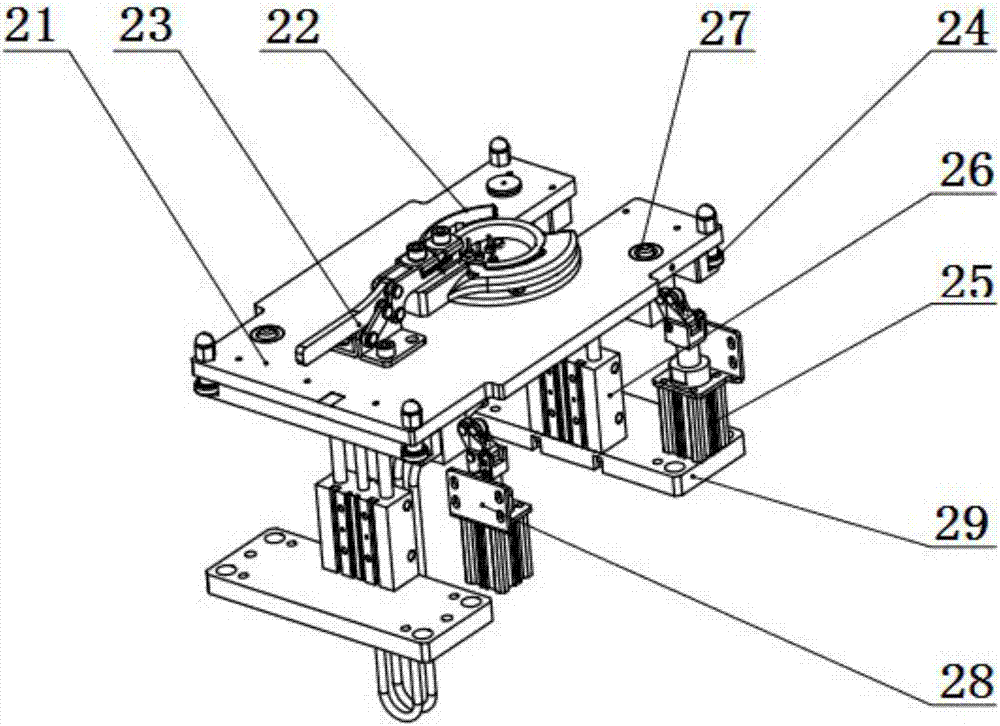

[0032] The tooling mechanism 2 is installed on the double-speed chain and realizes the positioning and clamping of the special-shaped heating tube, which facilitates the subsequent welding of the nut and the special-shaped heating tube. The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com