Magnetic attraction type damping fin magnetizing and punching device and production technology thereof

A production process and damping sheet technology, which is applied in the field of automobile damping, can solve the problems of short service life of conveyor belts, poor effective service life, and high cost of substitutes, and achieve the effects of improving efficiency, reducing harmful gases, and good viscoelastic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

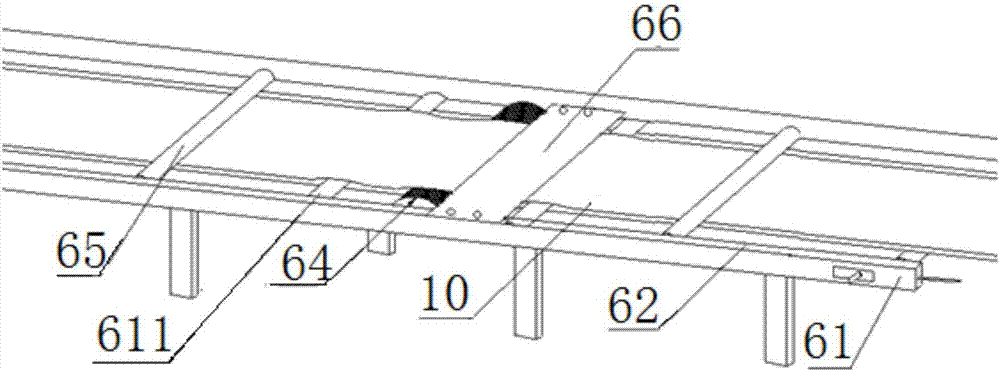

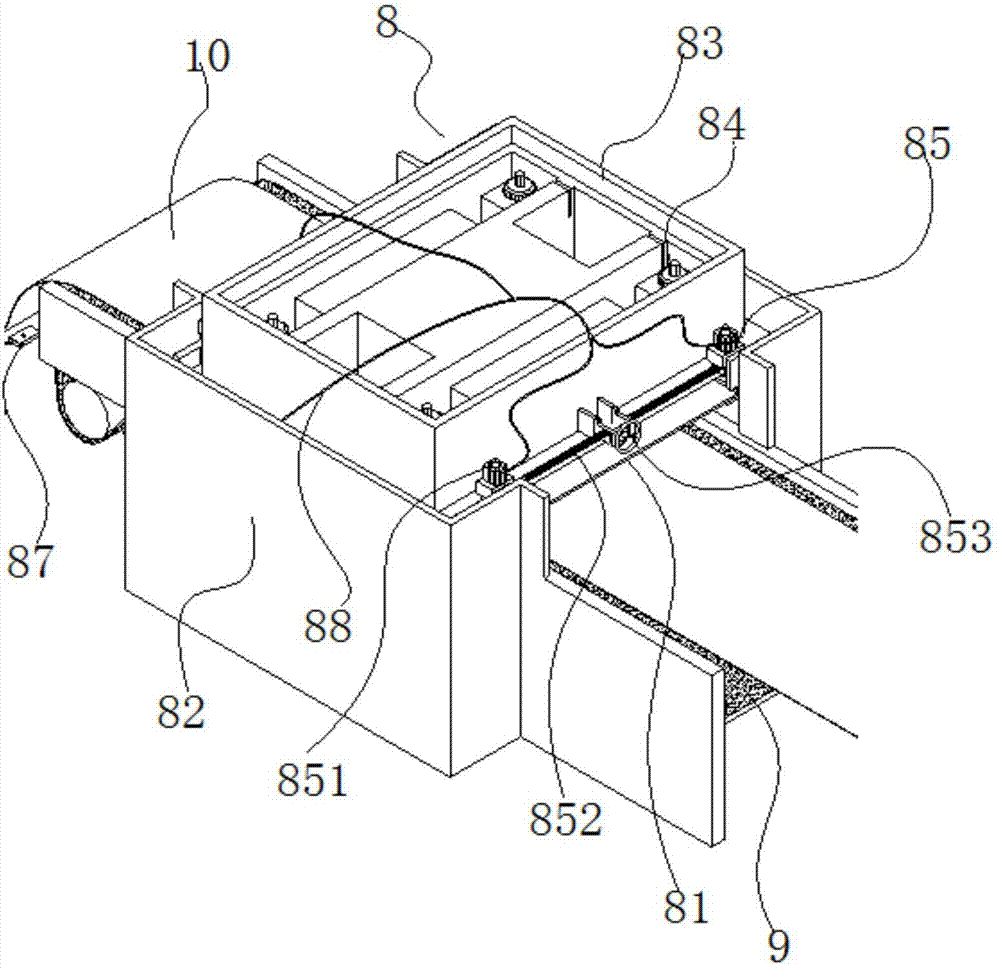

[0063] The magnetizing and punching device of the magnetic suction type damping plate in this embodiment includes a magnetizing mechanism 6 and a stamping and cutting mechanism 8 arranged in a process; wherein: as figure 1 As shown, the magnetizing mechanism 6 includes a magnetizing frame 61, a magnetizing conveyor belt 62, a magnetizing roller 64 and a pressing plate 66, and the magnetizing conveyor belt 62 is reciprocatingly laid on the surface of the magnetizing frame 61; The two ends of the roller 64 are detachably and fixedly connected with the magnetizing frame 61, and are suspended above the magnetizing conveyor belt 62; Magnetic roller 64, and reserve the gap that magnetic suction type damping sheet 10 can pass through, pressing plate 66 can squeeze and dehydrate the cooling water on the surface of magnetic suction type damping sheet, lay the foundation for the surface water absorption and drying of the next step; as figure 2 As shown, the stamping and cutting mechani...

Embodiment 2

[0083] The basic structure and ingredients of the magnetizing and punching device for the magnetic damping sheet in this embodiment are the same as those in Embodiment 1. The difference and improvement lies in that there are two pressing plates 66, and the two sides of the magnetizing roller 64 are in the shape of " Eight "shaped obliquely symmetrical settings, double-sided water pressure, improve efficiency; the lifting height adjustment mechanism 84 is 4 lifting screws symmetrically arranged at the four corners of the stamping table 83, and the lifting can be adjusted in a balanced manner at the four corners to ensure punching. The balance of the cutting surface; the bottom of the front end of the die-cutting conveyor belt 9 is provided with a damping sheet induction mechanism 87, and when no damping sheet passes through, the control mechanism can be notified to stop punching, so as to avoid damage to the conveyor belt by die cutting.

[0084] The production process of the ma...

Embodiment 3

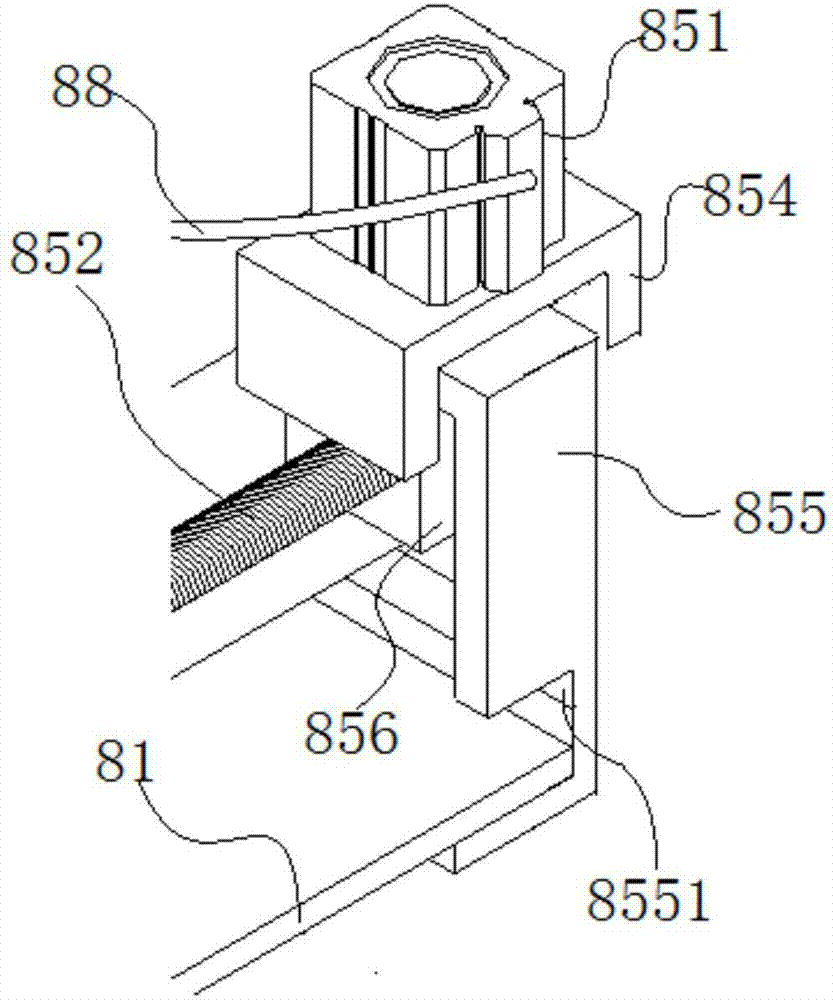

[0103] The basic structure and ingredients of the magnetizing and punching device for the magnetic suction type damping sheet in this embodiment are the same as those in Embodiment 2. The difference and improvement are that the punching and cutting mechanism 8 also includes , the 2 die width adjustment mechanisms 85 directly above the punching conveyor belt 9 are adjusted accordingly according to the die specifications to improve the versatility of the device; Fixed on the magnetizing frame 61, symmetrically arranged on the magnetizing conveyor belt 62, and a gap is reserved between the magnetizing conveyor belt 62; the bottom of the magnetizing conveyor belt 62 is also provided with an idler 611, which cooperates with the pressing plate 66 to squeeze out Moisture blots dry.

[0104] The component of step one batching comprises the magnetic powder of 350 kilograms, the superfine light calcium powder of 250 kilograms particle diameter 0.5~1 μ m; Ethylene-vinyl acetate copolyme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com