Air conditioner shell extrusion processing method

A technology of an air conditioner shell and a processing method, which can be applied to other household appliances, household appliances, household components, etc., can solve the problems of high cost, pollution, increased cost, etc., and achieve high bonding stability, stable bonding, and guaranteed pressure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] An extrusion processing method for an air conditioner casing described in this embodiment, the specific steps are as follows:

[0034] (1) Ingredients, proportioning plastic materials used in the production of air conditioner shells;

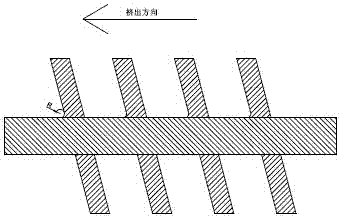

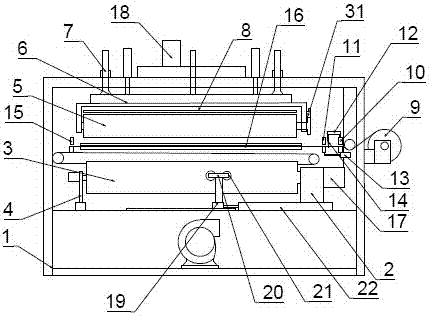

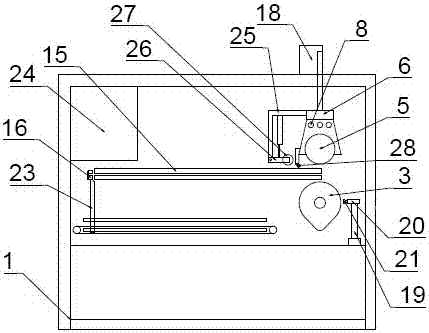

[0035] (2) Extrusion molding, using a plastic extruder with a mold to extrude a tubular body, such as figure 1 As shown, based on the extruding direction of the extruder, the front end side of the screw rib on the screw rod and the screw groove are transitioned by a chamfer, and the chamfer R between the screw rib and the screw groove on the screw rod is 1.2mm ,; At the same time, the gap between the screw and the barrel of the extruder is 6 μm; each track of the multi-claw tractor used in the extrusion process is individually controlled by a power mechanism;

[0036] (3) Holes are formed on the side wall of the tubular body by laser cutting or machine tool engraving to form through holes for installing accessories or as air inlet and ou...

Embodiment 2

[0038] An extrusion processing method for an air conditioner casing described in this embodiment, the specific steps are as follows:

[0039] (1) Ingredients, proportioning plastic materials used in the production of air conditioner shells;

[0040] (2) Extrusion molding, using a plastic extruder to cooperate with a mold to extrude a tubular body, wherein the side of the screw edge on the screw at the front end of the extrusion direction of the extruder and the screw groove are transitioned by chamfering, and the screw The chamfer R between the screw edge and the screw groove is 1 mm; at the same time, the gap between the screw and the barrel of the extruder is 4 μm; each track of the multi-claw tractor used in the extrusion process passes through a The power mechanism is controlled separately;

[0041] (3) Holes are formed on the side wall of the tubular body by laser cutting or machine tool engraving to form through holes for installing accessories or as air inlet and outle...

Embodiment 3

[0044] An extrusion processing method for an air conditioner casing described in this embodiment, the specific steps are as follows:

[0045] (1) Ingredients, proportioning plastic materials used in the production of air conditioner shells;

[0046] (2) Extrusion molding, using a plastic extruder to cooperate with a mold to extrude a tubular body, wherein the side of the screw edge on the screw at the front end of the extrusion direction of the extruder and the screw groove are transitioned by chamfering, and the screw The chamfer R between the screw edge and the screw groove is 1.6mm; at the same time, the gap between the screw and the barrel of the extruder is 5μm; each track of the multi-claw tractor used in the extrusion process passes through the A power mechanism is controlled separately;

[0047] (3) Holes are formed on the side wall of the tubular body by laser cutting or machine tool engraving to form through holes for installing accessories or as air inlet and outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com