Strip conveying device used for ultrasonic consolidation additive manufacturing machine

A technology of ultrasonic consolidation and additive manufacturing, which is applied to cleaning methods using liquids, winding strips, transportation and packaging, etc., can solve problems such as increasing equipment service life, increasing raw material supply costs and raw material processing costs, and achieving The effect of reducing supply costs and reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

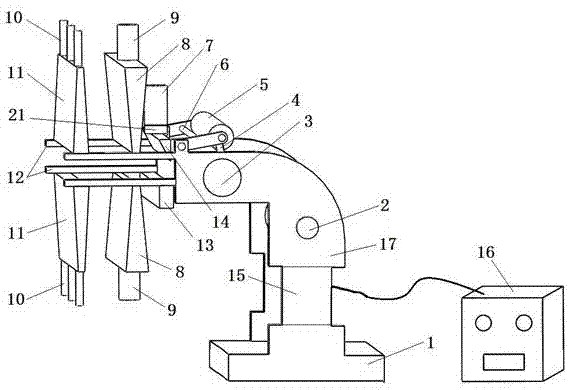

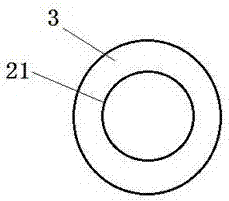

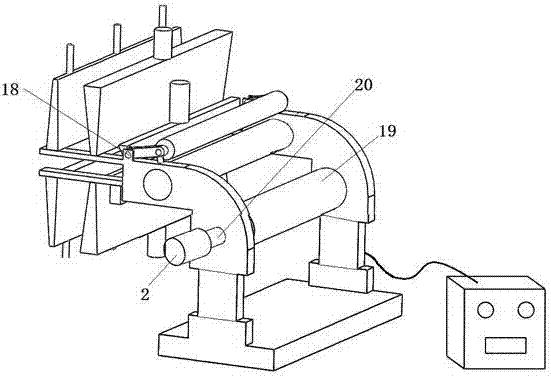

[0022] Such as figure 1 , figure 2 , image 3 As shown, the present invention is used for the belt feeding device of ultrasonic consolidation additive manufacturing machine, including base 1, frame 17, belt feeding roller 19, and also includes lifting mechanism 15, first straightening roller 3, second straightening roller 5. The conveying track 12, the cutting knife 14, the base 1 is provided with a lifting mechanism 15, and a frame 17 is arranged above the lifting mechanism 15. The frame 17 is L-shaped. One section of the frame 17 is coaxially connected with the lifting mechanism 15, and the other section Vertical to the lifting mechanism 15; the frame 17 is provided with a tape feed roller 19, the first straightening roller 3, the tape feed roller 19 is arranged below the frame 17 and is located on a section of the frame 17 coaxial with the lifting mechanism 15, the first A straightening roller 3 is arranged on the top of the belt feeding roller 19 and is positioned on a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com