An integrated automatic sand unloading device for oil well site fracturing construction and its working method

An automatic unloading and oil well technology, which is applied in the direction of transportation and packaging, load hanging components, cranes, etc., can solve the problems of not being able to meet the requirements of sand addition, high manual labor intensity, and low efficiency, and achieve stable and reliable structural design, reduce Small footprint and high hoisting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

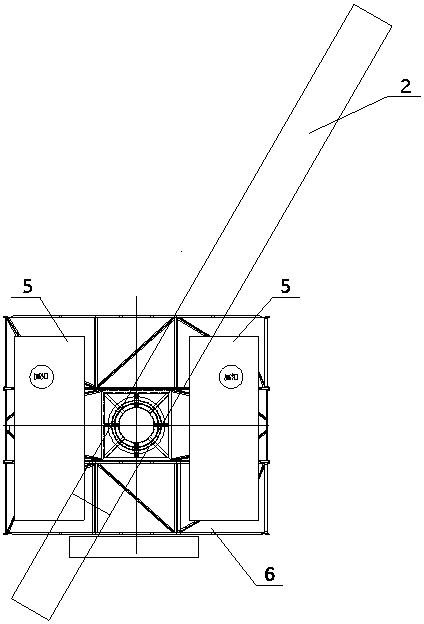

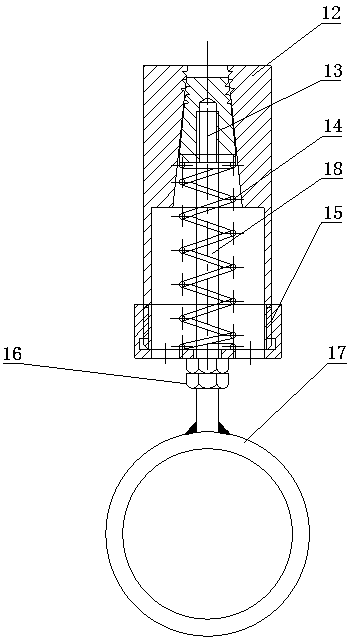

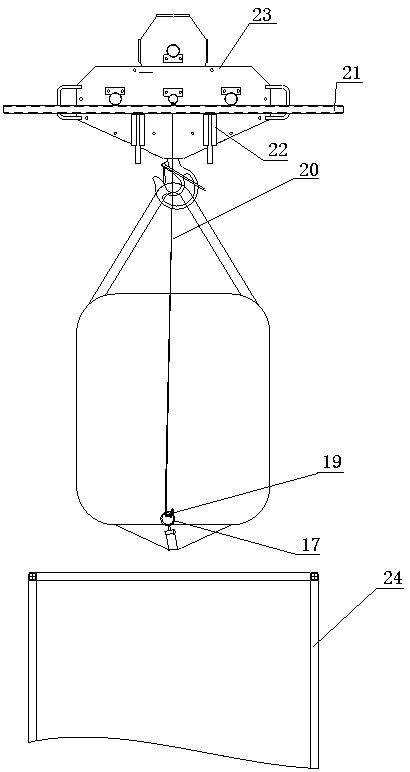

[0024] The embodiment of the present invention provides an integrated device for automatic sand unloading in oil wellsite fracturing construction, which includes a crane, a sand storage tank 5, a lifting mechanism 7, a slewing mechanism 9, a luffing mechanism 8, a frequency conversion program control system, and a sand bag release Rope device and sand bag rope locker. The crane includes a column 3 and a swing arm. The crane base is rigidly connected to the sand storage tank base set on both sides of the crane column to form an 8.7mX7.5m integral base 6. The upper part of the sand storage tank 5 and the column 3 are connected by a connecting brace 10. A revolving mechanism 9 is provided between the swing arm and the column 3, and the swing arm...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap