Rubber composition for coating steel wire cord of radial tire for engineering machinery

A radial tire and rubber composition technology, applied in the field of tire rubber, can solve the problems of heavy load bearing, harsh use environment, and slow driving speed, and achieve the effects of good aging resistance, high adhesive force, and high modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

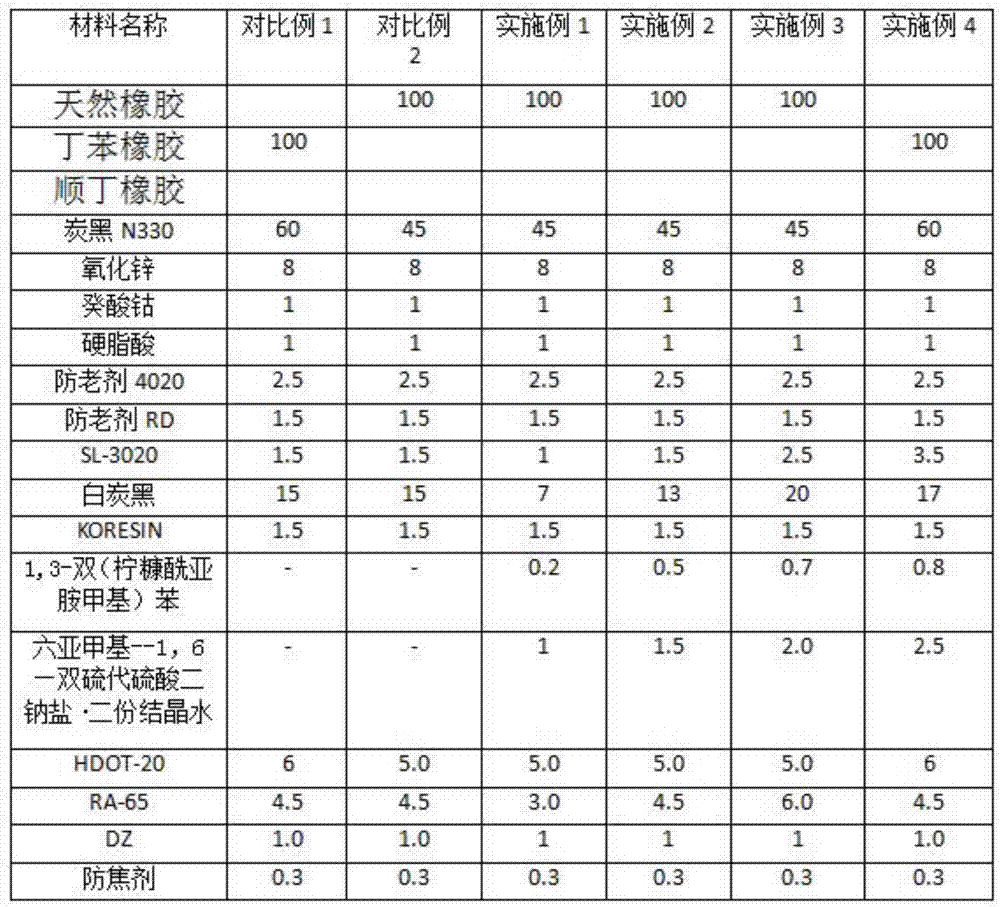

Method used

Image

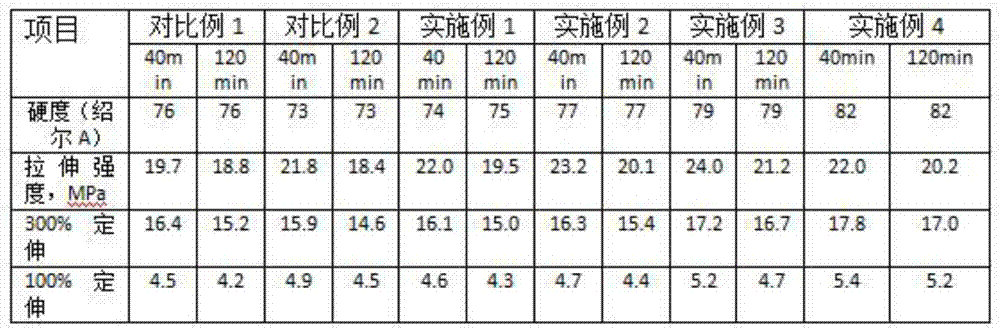

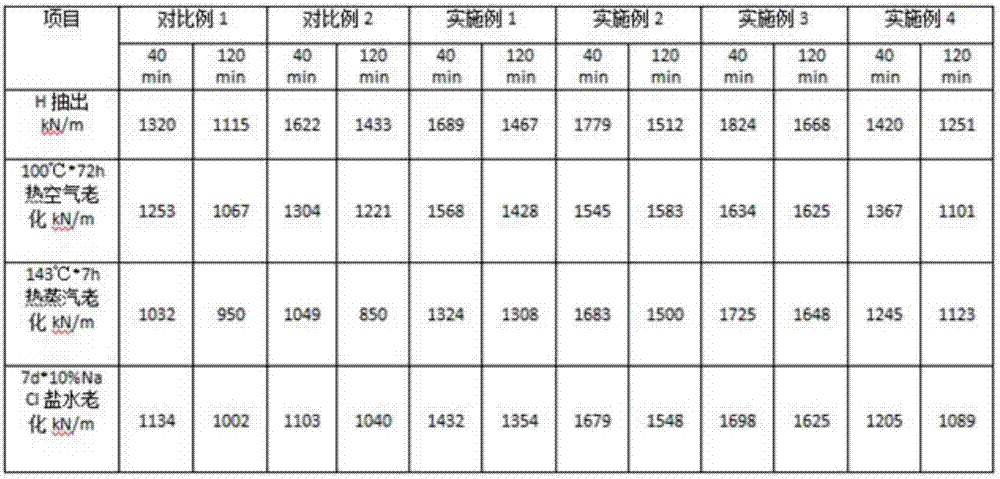

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with embodiment:

[0009] The present invention is used for the steel cord coating rubber composition of engineering machinery tire, can adopt following manufacturing method, concrete steps are as follows:

[0010] 1. Put the rubber component, zinc oxide, cobalt salt, dispersant, anti-aging agent, organic acid, and 2 / 3 carbon black into the GK400 ZZ rotor mixer at a speed of 40±3 rpm, and mix for 2.5- Mixed rubber A was obtained in 4 minutes, and the discharge temperature was controlled at 155-165°C.

[0011] 2. Add the remaining carbon black, white carbon black, binder SL-3020, phenolic resin, hexamethylene-1,6-dithiosulfuric acid disodium salt, two parts of crystal water, 1,3-bis (Citroimidomethyl)benzene and rubber compound A were added to the GK400 ZZ rotor internal mixer at a speed of 28±3 rpm, and mixed for 2.5-4min to obtain rubber compound B, and the temperature of the rubber was controlled. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com