Preparation method of calcium molybdate/molybdenum disulfide composite luminescent material

A luminescent material, molybdenum disulfide technology, applied in luminescent materials, chemical instruments and methods, etc., to achieve the effect of wide application range, concentrated green light spectrum, and narrow blue light emission spectrum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

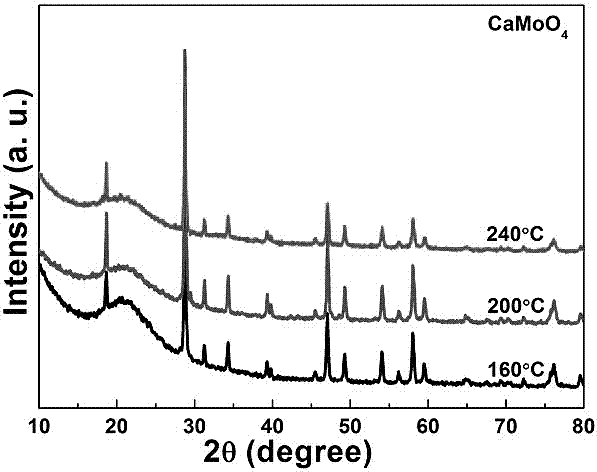

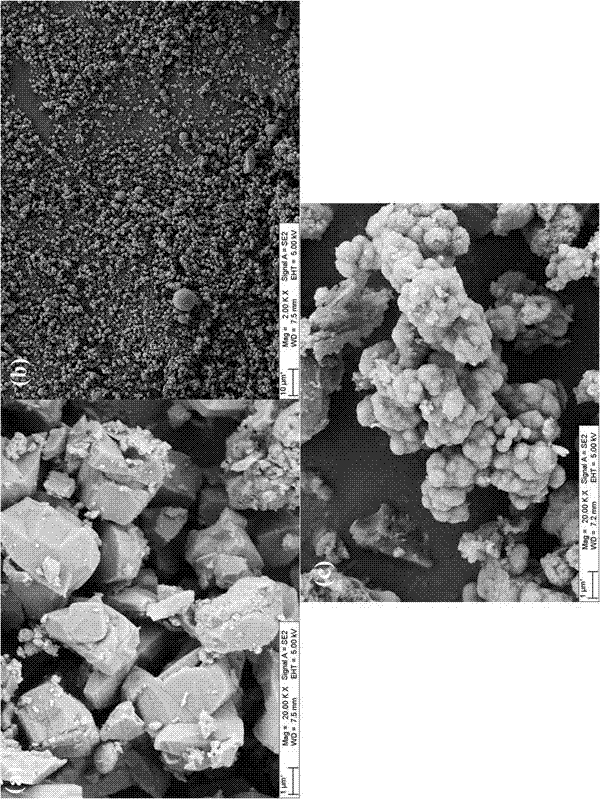

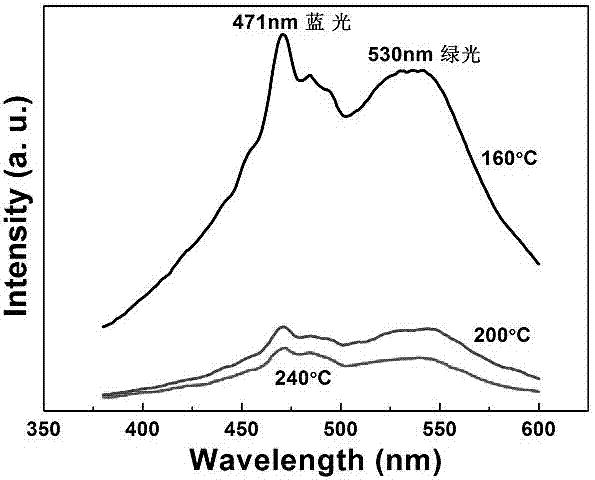

Embodiment 1

[0014] 0.85g sodium molybdate (Na 2 MoO 4 ) in 30mL of water, stirred for 5 minutes to form a sodium molybdate aqueous solution, poured the sodium molybdate aqueous solution into the polytetrafluoroethylene lining, soaked two egg shells in water, and then removed the inner membrane attached to the egg shell Put it into the aqueous solution of sodium molybdate; put the polytetrafluoroethylene liner into the reaction kettle, seal it and put it in a dry box for 24 hours at 160°C. After taking out the product, wash it with deionized water and absolute ethanol until it is neutral. Then dry at 40°C for 12 hours to obtain a brown calcium molybdate / molybdenum disulfide composite luminescent material. Put the composite luminescent material into a fluorescence spectrometer to test its luminescent properties. The excitation wavelength is 254nm, showing obvious blue and green light emissions.

Embodiment 2

[0016] 0.85g sodium molybdate (Na 2 MoO 4 ) in 30mL of water, stirred for 5 minutes to form a sodium molybdate aqueous solution, poured the sodium molybdate aqueous solution into the polytetrafluoroethylene lining, soaked two egg shells in water, and then removed the inner membrane attached to the egg shell Put it into the sodium molybdate aqueous solution; put the polytetrafluoroethylene liner into the reaction kettle, seal it and put it in a dry box for 24 hours at 200°C. After taking out the product, wash it with deionized water and absolute ethanol until it is neutral. Then dry at 40°C for 12 hours to obtain a brown-black calcium molybdate / molybdenum disulfide composite luminescent material. The composite luminescent material was put into a fluorescence spectrometer to test its luminescent properties. The excitation wavelength was 254nm, showing obvious blue and green light emissions.

Embodiment 3

[0018] 0.85g sodium molybdate (Na 2 MoO 4 ) in 30mL of water, stirred for 5 minutes to form a sodium molybdate aqueous solution, poured the sodium molybdate aqueous solution into the polytetrafluoroethylene lining, soaked two egg shells in water, and then removed the inner membrane attached to the egg shell Put it into an aqueous solution of sodium molybdate; put the polytetrafluoroethylene liner into the reaction kettle, seal it and place it in a dry box for 24 hours at 240°C to react for 24 hours. After taking out the product, wash it with deionized water and absolute ethanol until it is neutral. Then dry at 40°C for 12 hours to obtain a black calcium molybdate / molybdenum disulfide composite luminescent material. The composite luminescent material was put into a fluorescence spectrometer to test its luminescent properties. The excitation wavelength was 254nm, showing obvious blue and green light emission.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com