Production method for medium-silicon low-carbon low-phosphorus manganese block ferroalloy

A technology of carbon and low-phosphorus manganese blocks and production methods, which is applied in the field of quality improvement and efficiency enhancement of leftover materials and comprehensive utilization of industrial waste, which can solve the problems of limited product quantity, unstable composition, and no alloy production, and achieve recycling The effect of high efficiency, large volatilization loss and low recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

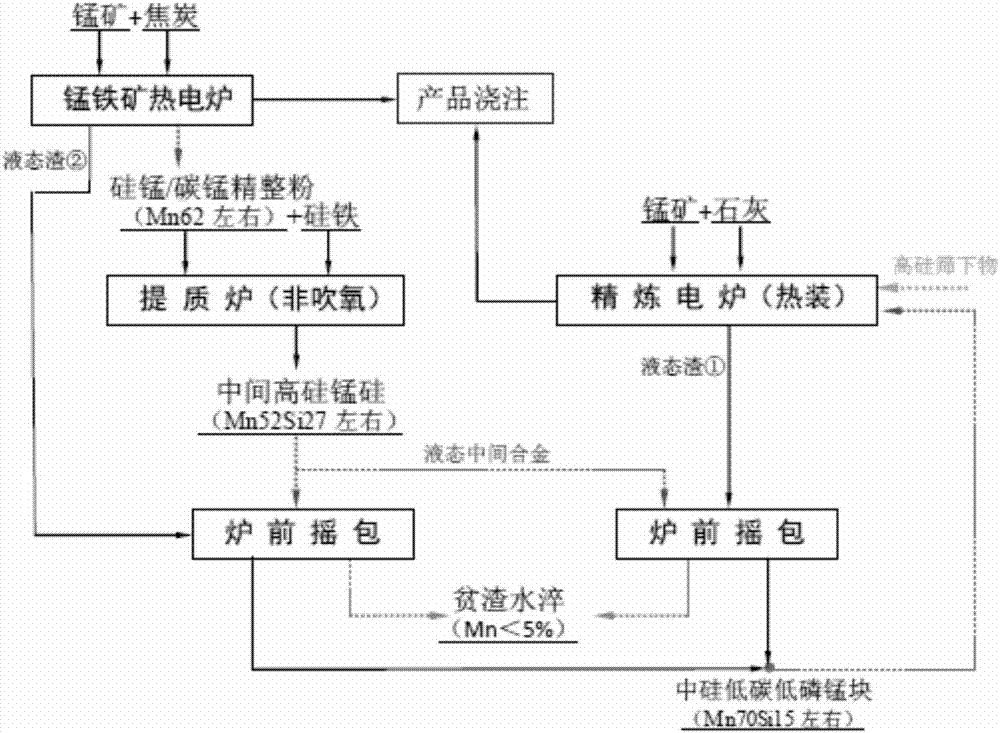

Method used

Image

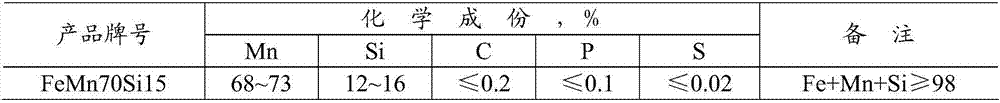

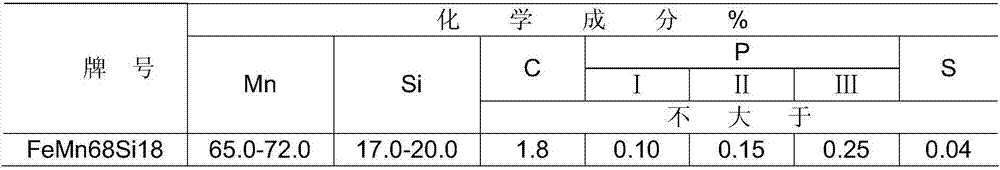

Examples

Embodiment 1

[0052] step one

[0053] The undersize powder produced during the product finishing of the electric furnace ferromanganese, in parts by mass, 100 parts of the undersize powder produced during the product finishing, 20 parts of the silicon-containing additives with 68wt% to 68.5wt% of silicon, oxidation 2 parts of decarburizing agent; sieve powder, silicon-containing additives (silicon-containing additives are ferrosilicon, the content of silicon in the ferrosilicon is 68wt%-68.5wt%), oxidizing decarburizing agent (oxidizing decarburizing Carbon agent is SiO 2 ); and the prepared undersize powder, silicon-containing additives, and oxidative decarburizing agent are added to the upgrading furnace, and after the upgrading furnace is heated, the carbon is reduced and upgraded, a liquid low-carbon manganese-silicon master alloy is obtained; The mass percentage of Mn in the undersize powder is 60%.

[0054] Step two

[0055] The liquid manganese slag A that is by-produced in the process o...

Embodiment 2

[0070] Other parameters are completely the same as in Example 1, except that the mass percentage of Mn in the undersize powder is 65%;

[0071] Table 2

[0072]

[0073] It can be seen from the examples that the composition of the product obtained by the present invention is already very stable, which completely exceeds the stability of the finished composition in the prior art.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com