Turmeric saponin extraction method without waste emission

An extraction method and technology of turmeric saponin, applied in the directions of inorganic fertilizers, steroids, organic chemistry, etc., can solve the problems of high treatment cost, dust pollution, waste of resources, etc., and reduce the difficulty of wastewater treatment and the loss of gasoline volatilization. , The effect of saving cleaning water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

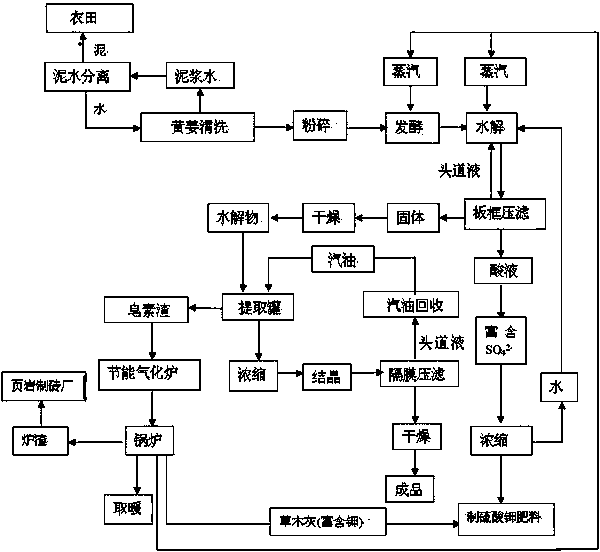

[0031] Example 1 A method for extracting turmeric saponin without waste discharge, comprising the following steps, (for its technical process see figure 1 ) :

[0032] 1) Cleaning: 135Kg of fresh turmeric is transported to the production line. First, the silt mixed with turmeric is screened out by a drum screen machine, and then the turmeric is washed with water. After the mud water produced is treated by sedimentation, the bottom sediment mud, which accounts for 25% of the cleaning water consumption, is reduced to the paddy field , and the remaining 75% supernatant returns to the ginger cleaning process.

[0033] 2) Crushing: The cleaned turmeric directly enters the crusher for crushing, and the diameter of the screen used is between 60-100 mesh.

[0034] 3) Fermentation: The crushed turmeric material enters the fermentation tank, and steam is passed into the fermentation tank to make the temperature reach 43 。 C, kept at a constant temperature for 35.5 hours to obtain a...

Embodiment 2

[0040] Example 2 A method for extracting turmeric saponin without waste discharge, comprising the following steps, (for its technical process see figure 1 ):

[0041] 1) Cleaning: 67.5 tons of fresh turmeric is transported to the production line. First, the silt mixed with turmeric is screened out by a drum screen machine, and then the turmeric is washed with water. After the mud water is processed by sedimentation, the bottom sediment mud, which accounts for 25% of the cleaning water consumption, is reduced. paddy fields, and the remaining 75% supernatant returns to the turmeric cleaning process.

[0042] 2) Crushing: The cleaned turmeric directly enters the crusher for crushing, and the diameter of the screen used is between 60-100 mesh.

[0043] 3) Fermentation: The crushed turmeric material enters the fermentation tank, and steam is passed into the fermentation tank to make the temperature reach 45 。 C, kept at a constant temperature for 36 hours to obtain a fermented ...

Embodiment 3

[0049] Example 3 A method for extracting turmeric saponin without waste discharge, comprising the following steps, (for its technical process see figure 1 ) :

[0050] 1) Cleaning: 135 tons of fresh turmeric is transported to the production line. First, the silt mixed with turmeric is screened out by a drum screen machine, and then the turmeric is washed with water. After the muddy water is processed by sedimentation, the bottom sediment accounts for 25% of the cleaning water consumption. The mud is reduced to the paddy field, and the remaining 75% of the supernatant is returned to the turmeric cleaning process.

[0051] 2) Crushing: The cleaned turmeric directly enters the crusher for crushing, and the diameter of the screen used is between 60-100 mesh.

[0052] 3) Fermentation: The crushed turmeric material enters the fermentation tank, and steam is passed into the fermentation tank to make the temperature reach 48 。 After C, the temperature was maintained for 36.5 h ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com