Grain refining heat treatment method for Ti-44Al-4Nb-4V-0.3Mo alloy

A technology of ti-44al-4nb-4v-0.3mo and 1.ti-44al-4nb-4v-0.3mo is applied in the field of thermal processing technology of titanium aluminum alloy, which can solve the problems of unfavorable mechanical properties, titanium aluminum alloy casting, etc. Coarse grains of the structure and inability to obtain fine and uniform problems can reduce the reaction temperature, refine the structure and increase the reaction speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] 1. Heat the Ti-44Al-4Nb-4V-0.3Mo alloy to 1250°C, and perform isothermal forging, with a deformation of 80%;

[0016] 2. Air-cool the deformed Ti-44Al-4Nb-4V-0.3Mo alloy to make solid solution of Nb, V and Mo into the high-temperature α phase of Ti-44Al-4Nb-4V-0.3Mo alloy to obtain supersaturated Ti- α phase of 44Al-4Nb-4V-0.3Mo alloy;

[0017] 3. Put the Ti-44Al-4Nb-4V-0.3Mo alloy treated in step 2 in a high-temperature furnace at 950°C for 30 minutes, and cool down with the furnace to ensure the discontinuous reaction. A fine-grained titanium-aluminum alloy structure with a grain size of less than 5 μm is obtained.

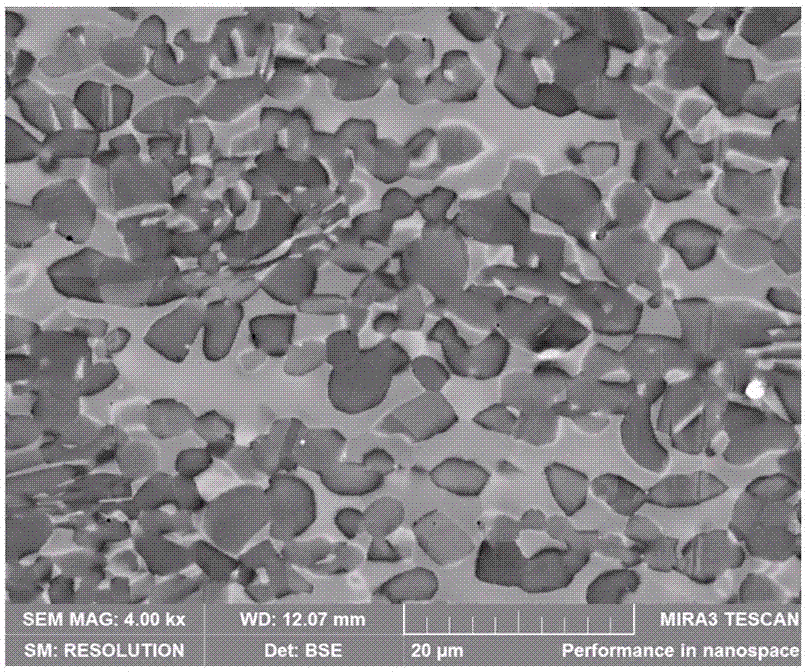

[0018] Adopt the backscatter imaging technique (SEM-BSE) under the scanning electron microscope to amplify 4000 times and detect this method to prepare fine-grained titanium-aluminum alloy, such as figure 1 shown by figure 1 It can be seen that the titanium-aluminum alloy prepared by this method is very fine.

Embodiment 2

[0020] 1. Heat the Ti-44Al-4Nb-4V-0.3Mo alloy to 1200°C, and perform isothermal forging, with a deformation of 85%;

[0021] 2. Air-cool the deformed Ti-44Al-4Nb-4V-0.3Mo alloy to make solid solution of Nb, V and Mo into the high-temperature α phase of Ti-44Al-4Nb-4V-0.3Mo alloy to obtain supersaturated Ti- α phase of 44Al-4Nb-4V-0.3Mo alloy;

[0022] 3. Put the Ti-44Al-4Nb-4V-0.3Mo alloy treated in step 2 in a high-temperature furnace at 1000°C for 30 minutes, and cool down with the furnace to ensure the progress of the discontinuous reaction. A fine-grained titanium-aluminum alloy structure with a grain size of less than 5 μm is obtained.

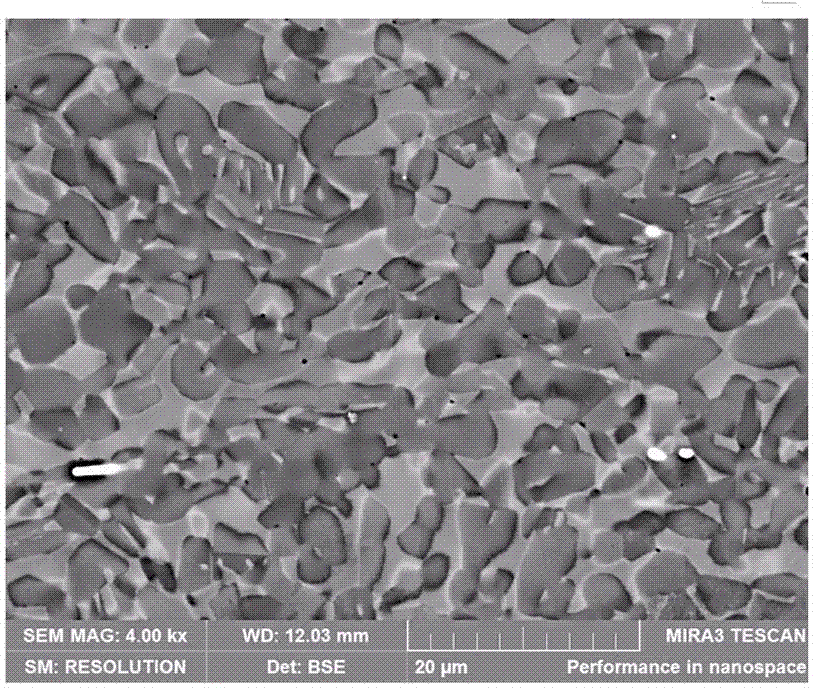

[0023] Adopt the backscatter imaging technique (SEM-BSE) under the scanning electron microscope to amplify 4000 times and detect this method to prepare fine-grained titanium-aluminum alloy, such as figure 2 shown by figure 2 It can be seen that the titanium-aluminum alloy prepared by this method is very fine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com