Novel composite insulation board

A composite thermal insulation, a new type of technology, applied in the direction of thermal insulation, building components, heating methods, etc., can solve the problems of organic material insulation board falling off, poor thermal insulation performance, high maintenance costs, etc., to promote health, good thermal insulation effect, improve fire prevention effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

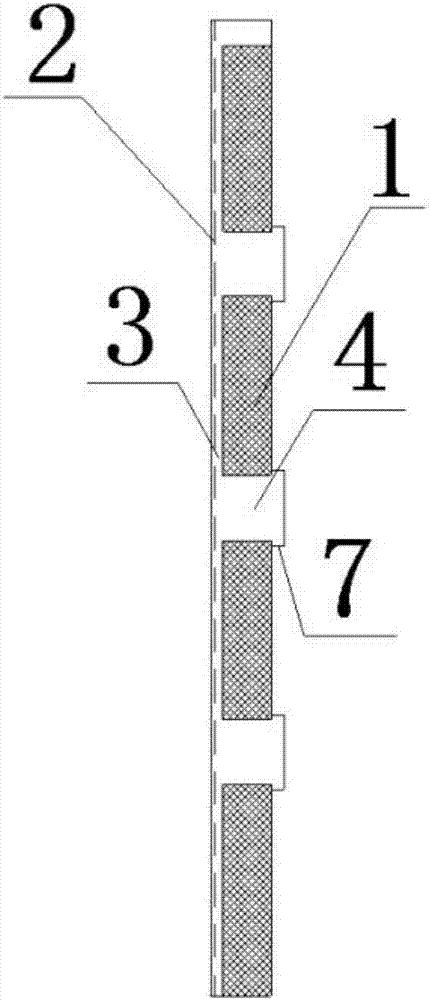

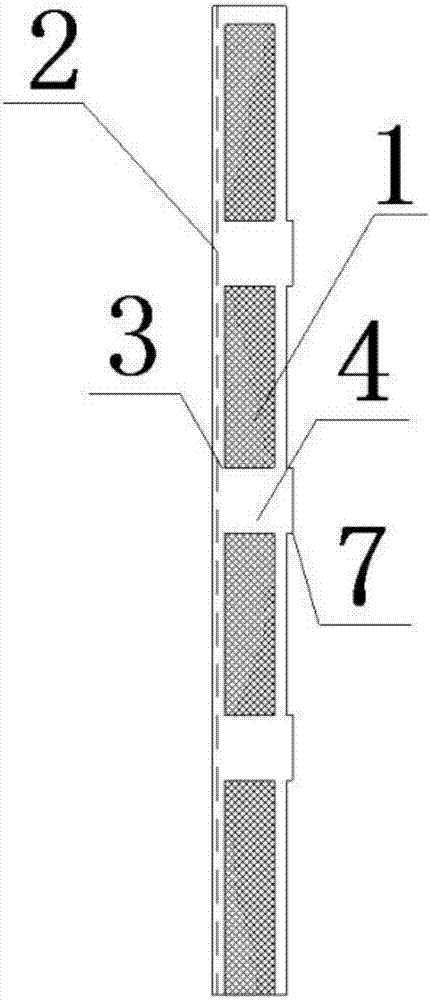

[0021] Such as Figure 1-2 As shown, a novel composite thermal insulation board of the present embodiment comprises an organic material thermal insulation layer 1 and an inorganic material thermal insulation layer 3 compounded together; the organic material thermal insulation layer 1 is provided with through holes 4 distributed at intervals; the inorganic material thermal insulation layer 3 is formed by pressing the inorganic thermal insulation material microbeads on one side of the organic material thermal insulation layer 1 , and the inorganic thermal insulation material microbeads fill and pass through the through holes 4 to form protrusions 7 on the other side of the organic material thermal insulation layer 1 .

[0022] The organic material insulation layer 1 of the present embodiment uses a polystyrene insulation board. First, a uniform cylindrical through hole 4 is opened on the organic material insulation layer 1, and then the organic material insulation layer 1 is hori...

Embodiment 2

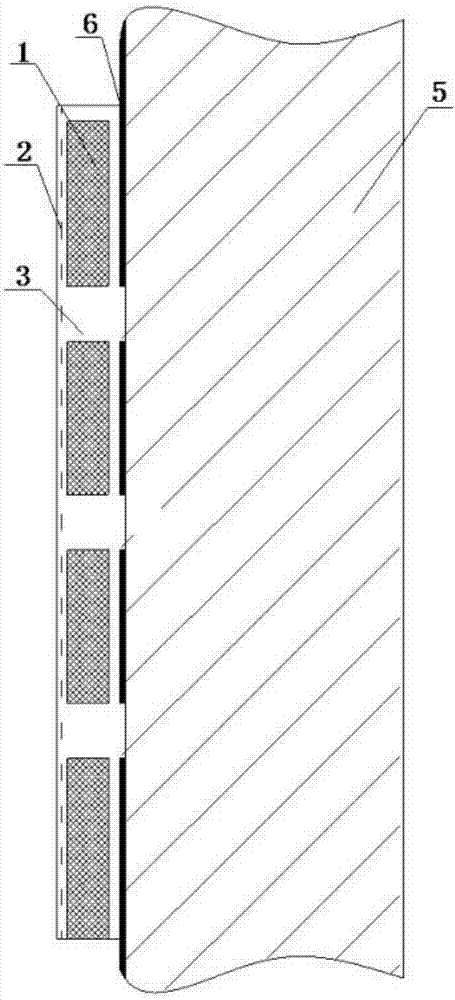

[0025] This embodiment is improved on the basis of Embodiment 1, and its difference is as follows image 3 As shown: both sides of the organic material insulation layer 1 in Example 2 are pressed with cement-based vitrified microbeads, the thickness of the side facing the wall is 3 to 20mm, and a plurality of cylindrical protrusions 7 are formed to achieve better the bonding effect.

[0026] When in use, the composite thermal insulation board of the present invention is no different from the traditional thermal insulation board, and the adhesive layer 6 is pasted on the surface of the shear wall 5 with cement; as image 3 As shown, the cylindrical protrusion 7 increases the contact surface area, and the cement is more closely bonded; and because the structure of the composite insulation board of the present invention is prefabricated before use, and the various characteristics of the inorganic insulation layer 3 are basically consistent with the cement , so the coefficient of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com