A wall coating and scraping machine for construction

A scraping machine and construction technology, which is applied in the direction of construction and building construction, can solve the problems of paint overflow, poor flatness with unevenness, inconsistent moisture content, etc., and achieve the effect of saving paint and smoothing the wall surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

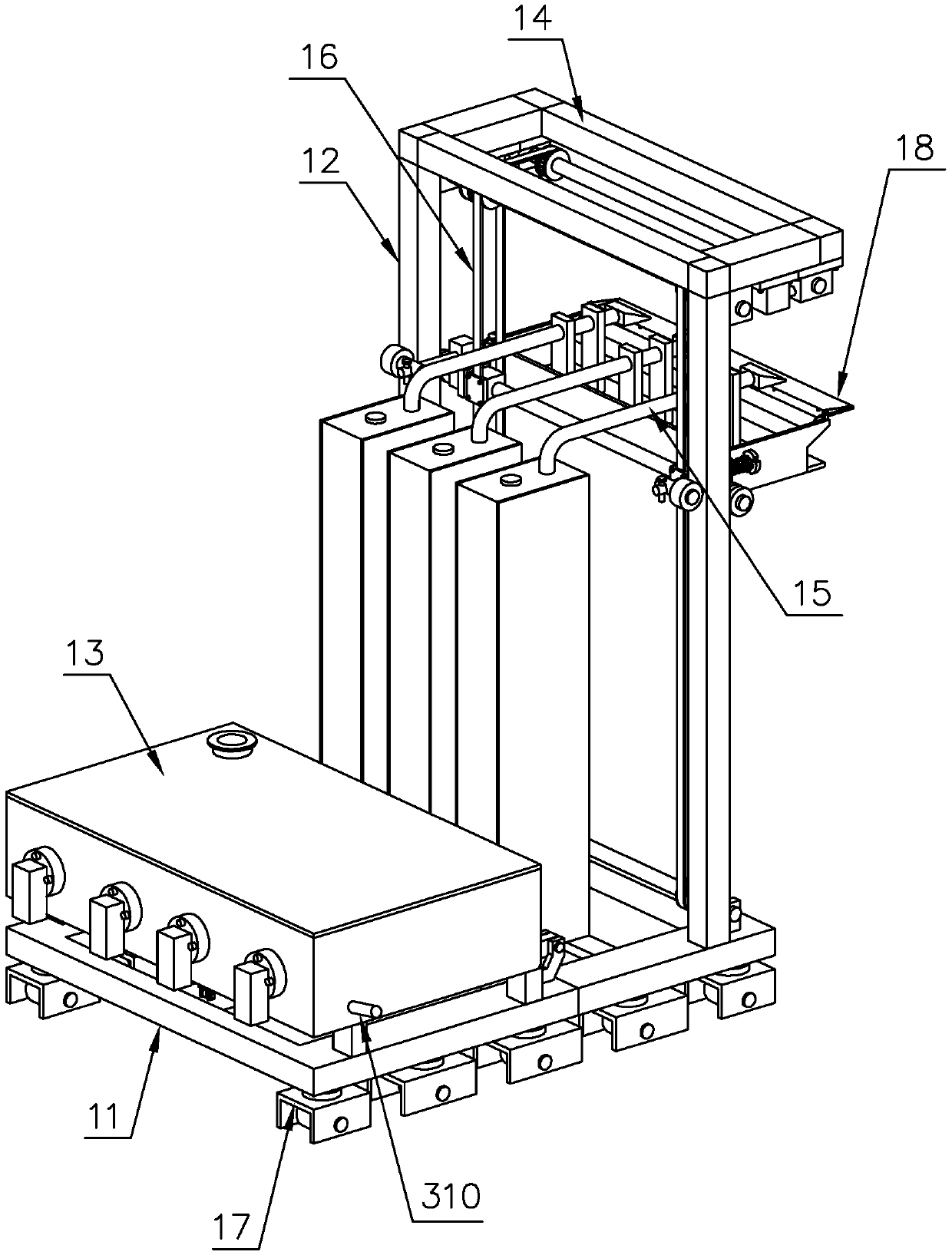

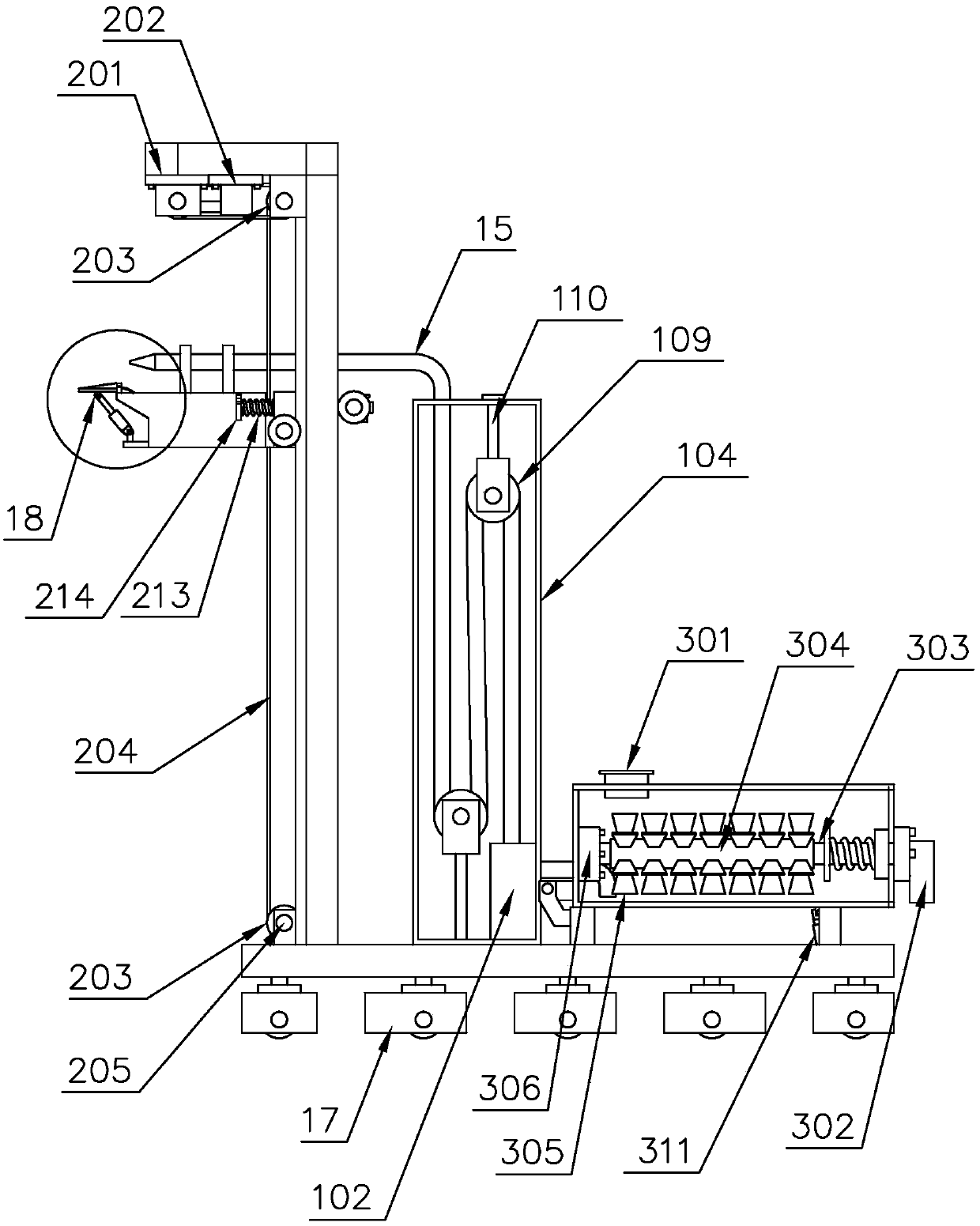

[0031] Example 1, such as Figure 1-6 Shown:

[0032] A kind of wall coating and scraping machine for construction, comprising a frame 11, a support arm 12, a box body 13, a top bracket 14, a spraying mechanism 15, a lifting mechanism 16, and universal wheels 17, and the upper part of the frame 11 is provided with a box body 13, the box body 13 is used to place wall paint;

[0033] The upper part of the box body 13 is provided with a mixing port 301, the side wall of the box body 13 is provided with a stirring motor 302, the shaft end of the stirring motor 302 is provided with a stirring shaft 303, and the two ends of the stirring shaft 303 are flexibly connected to the box body through a stirring bearing seat 306. 13 on the side wall, the stirring shaft 303 is provided with a stirring sheath 304, and the stirring sheath 304 is provided with a number of agitating blades 305, the agitating blades 305 are rubber blades, and the rubber blades can relieve the pressure of stirring...

Embodiment 2

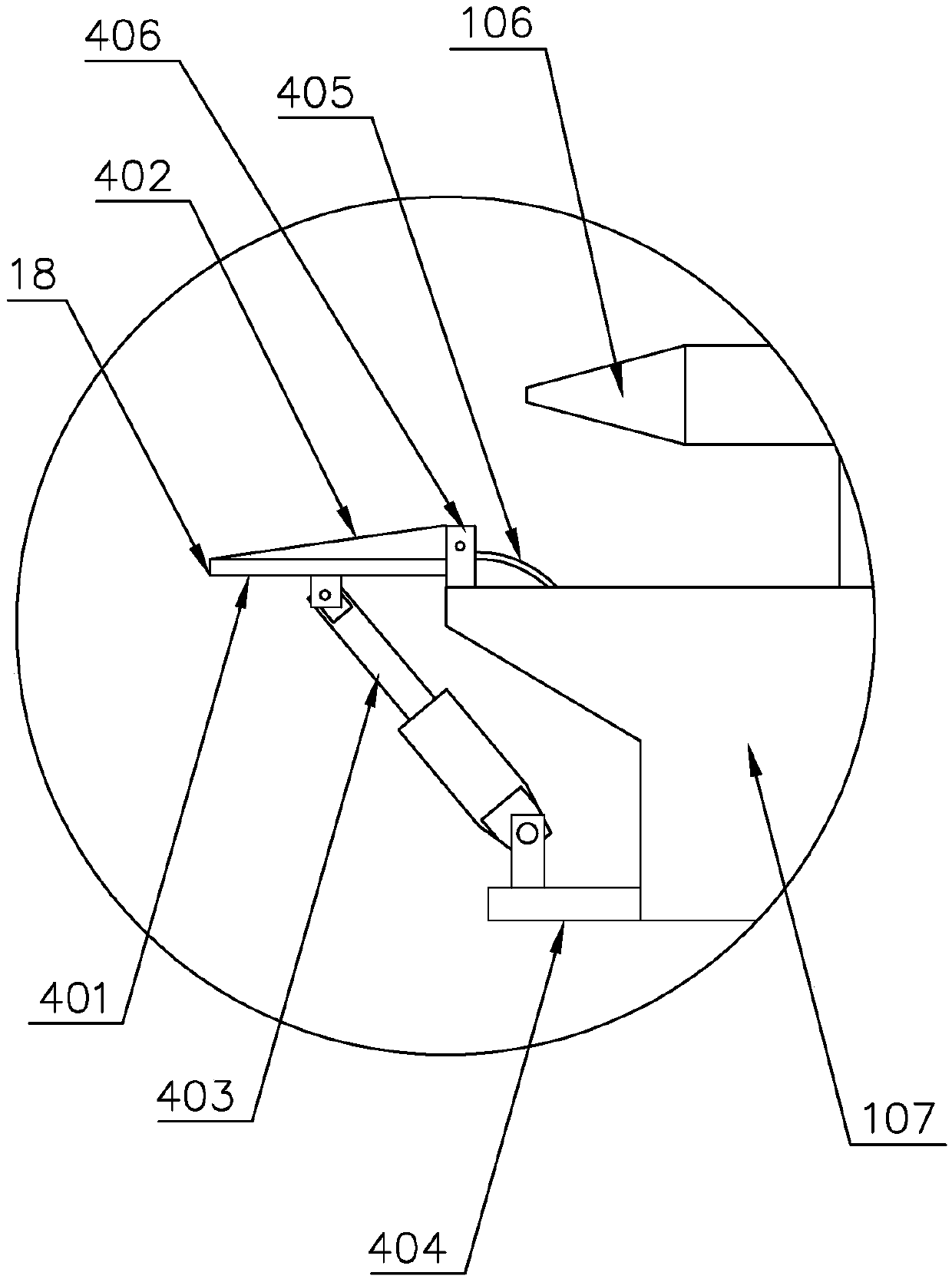

[0041] Example 2, such as Figure 7 Shown:

[0042] The difference from Embodiment 1 is that the support arm 12 is movably connected to the frame 11 through a pin shaft 503, a cylinder III 501 is provided on one side of the support arm 12, and a photoelectric ranging sensor 502 is provided on the top bracket 14. The model of the photoelectric distance measuring sensor 502 is CP35MHT80. It is adjusted by the ejection of the cylinder III501, and the support arm 12 is kept relatively parallel to the wall. The distance between the support arm 12 and the wall surface is accurately measured by the photoelectric distance measuring sensor 502, thereby reducing scratch The relative pressure of the board on the wall surface makes the wall surface evenly stressed, and further makes the wall surface spray and scrape smooth.

[0043] A wall coating and scraping machine for construction, the working process is as follows: the rollers at the bottom of the frame realize the free movement of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com