Effusion bubblization and atomization method used for gas well stimulation

A liquid accumulation and gas well technology, which is applied in the field of liquid accumulation bubble atomization for gas well stimulation, can solve the problems such as gas cannot be discharged smoothly, achieve the effects of reducing environmental pollution and operation times, low cost, and reducing dosing concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

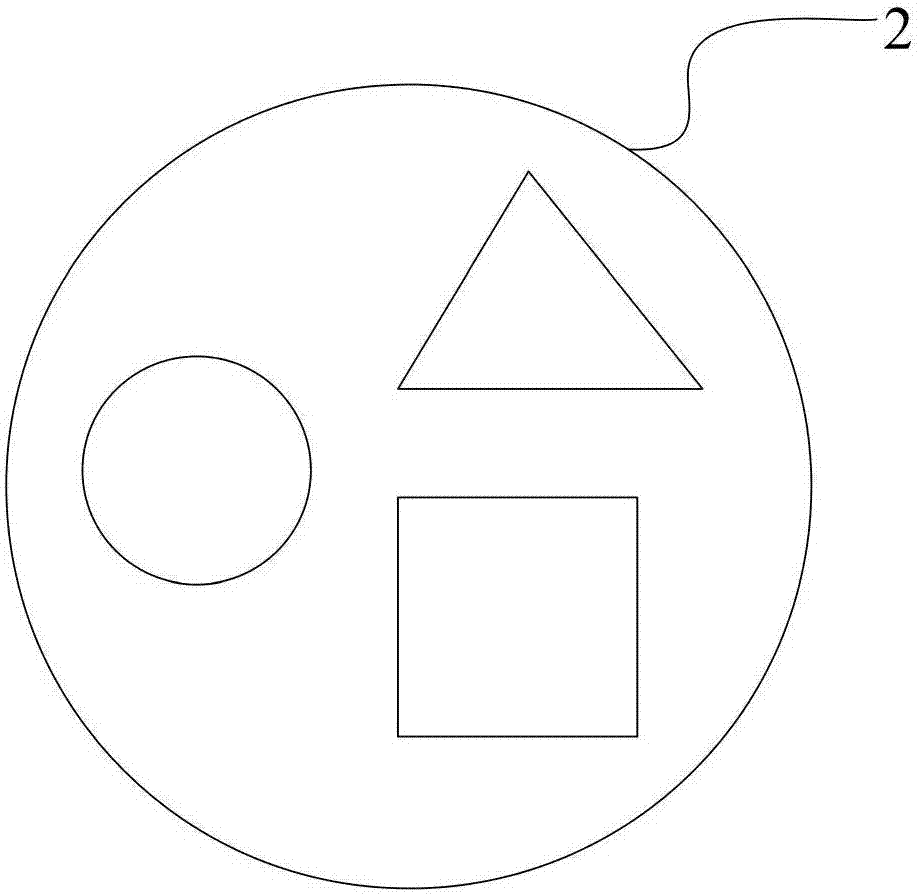

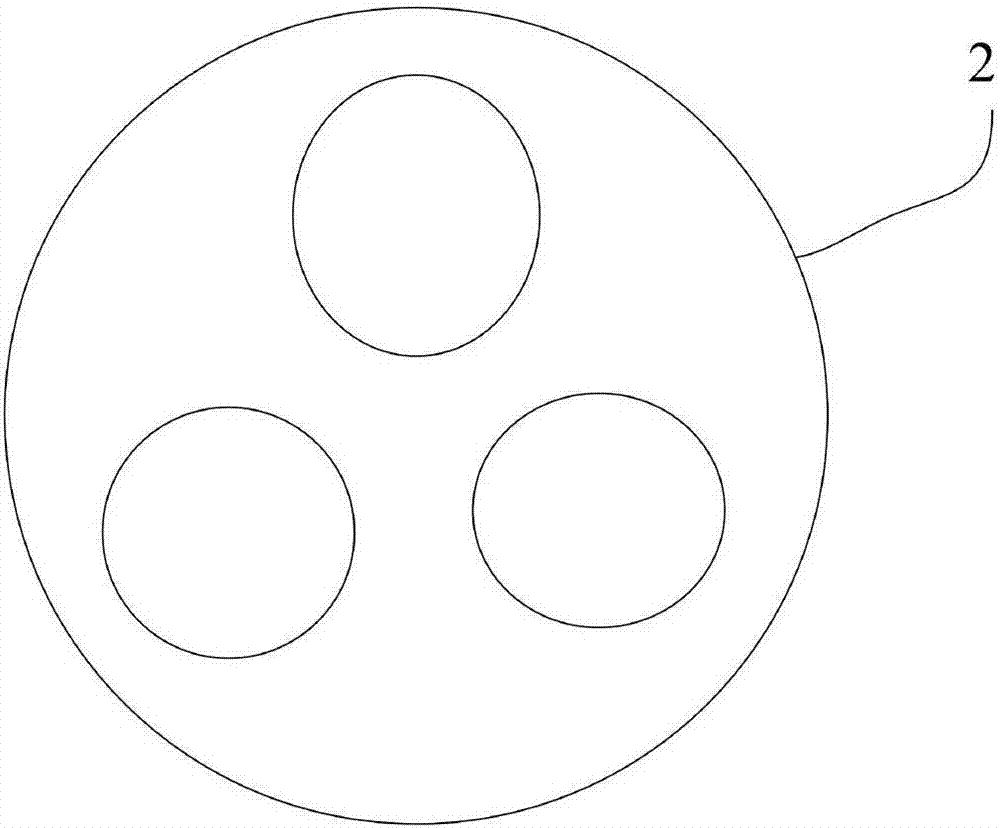

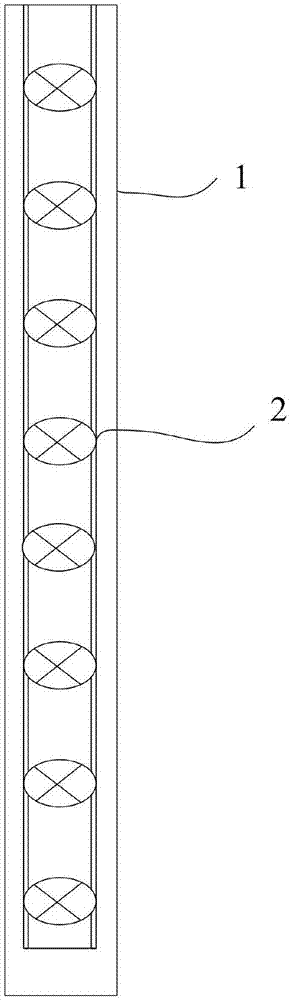

[0024] Example 1, such as Figure 1 to Figure 3 As shown, this embodiment provides a liquid bubble atomization method for gas well stimulation. The production of formation water is often accompanied by the production of formation water, which accumulates at the bottom of the well, affecting the gas in the formation from entering the bottom of the well and reaching the ground through the wellbore. , when the production of the gas well is low, the effusion flows back along the wall of the wellbore, making it difficult to discharge the wellbore, and accumulates at the bottom of the wellbore to hinder the production of gas. Usually, it is through gas lift, foam row, throwing foam rods, replacing small-diameter tubing, etc. Although these methods can remove fluid accumulation and increase the production of gas wells, artificial lifting and continuous input of chemical agents will not only increase production costs but also cause some pollution to the environment. The specific meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com