Carbocycle sealing structure similar to surface texture of dorsal carapaces of desert beetles

A carbon ring sealing and surface texture technology, applied in the direction of engine seals, engine components, mechanical equipment, etc., can solve problems such as large leakage and poor dynamic pressure effect, increase flow, prevent stiffness reduction or Deficiency, the effect of reducing retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing

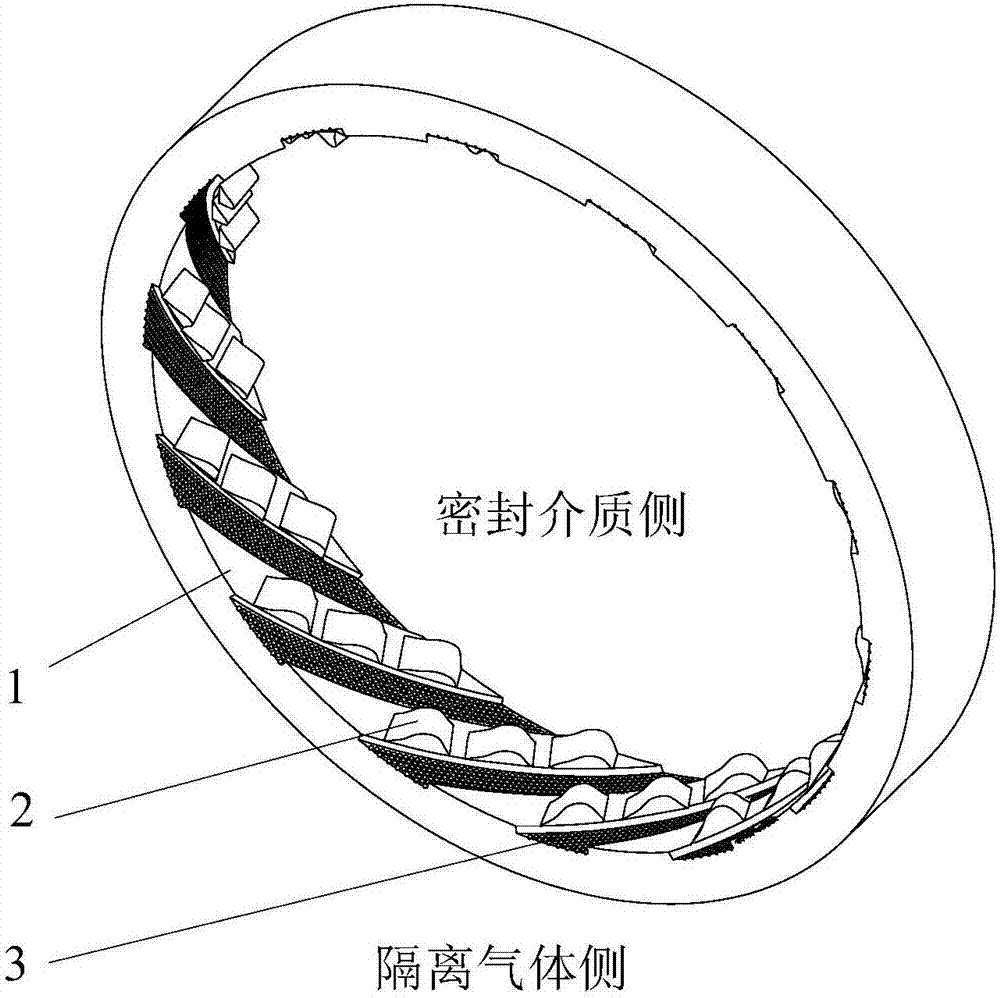

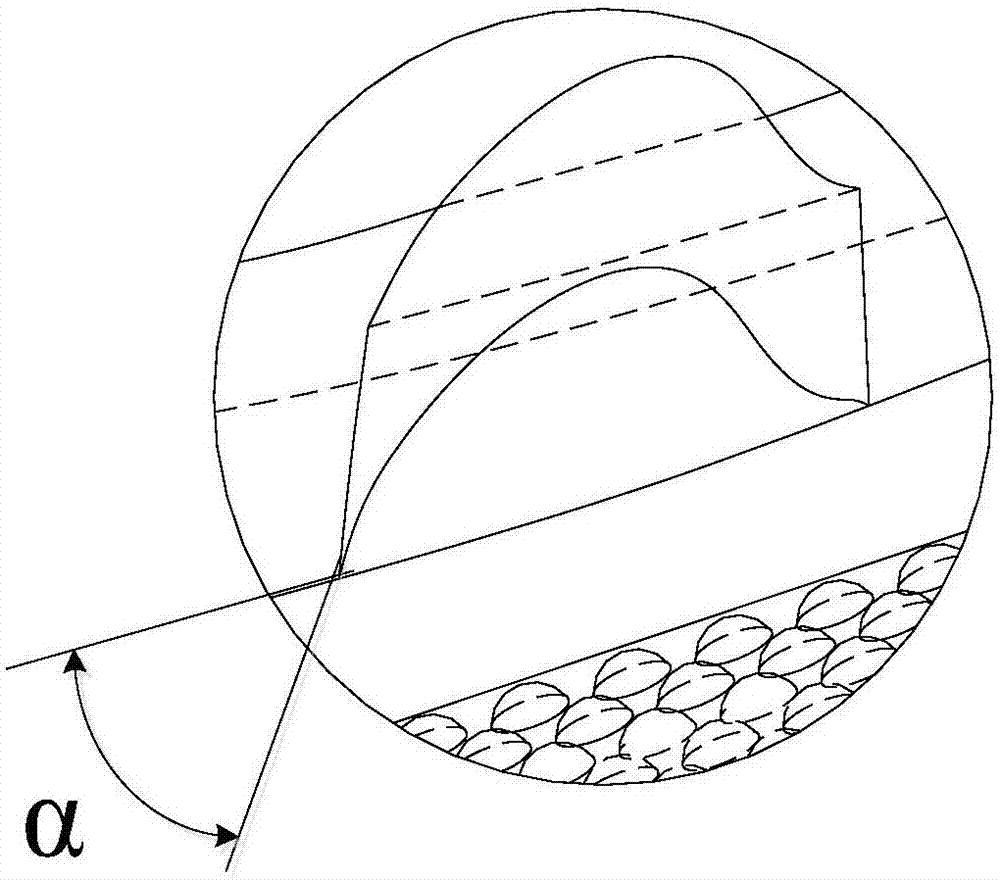

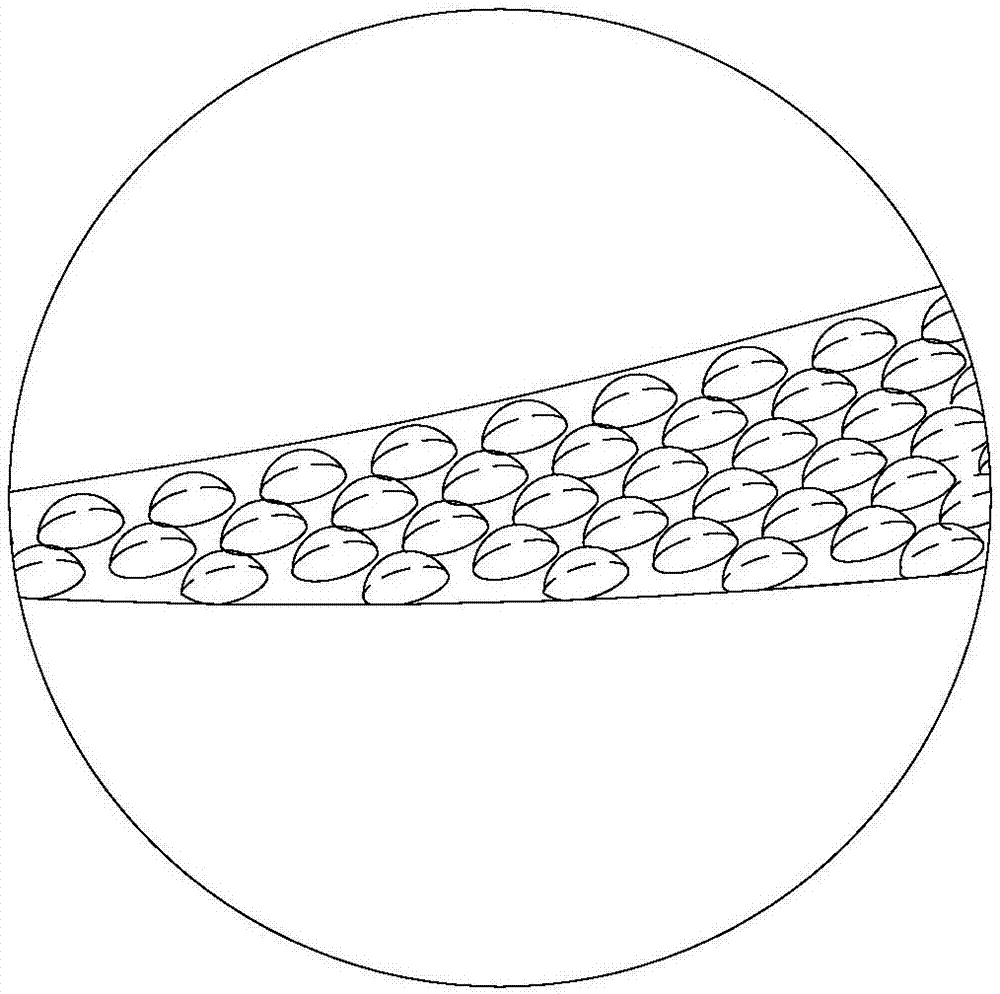

[0016] see figure 1 To Fig. 3: A carbon ring seal structure imitating the surface texture of the desert beetle's back shell, the axial side of the carbon ring seal is the sealing liquid side, and the other side is the isolated gas side, and the pressure of the isolated gas is low 0.05-0.15MPa in the sealing liquid; the inner diameter side surface of the carbon ring seal and the shaft surface of the machine to be sealed constitute a pair of sealing pairs, and the inner diameter side surface is composed of a smooth hydrophilic surface uniformly distributed in the circumferential direction 1, imitation fin diversion Consists of protrusions 2 and helical grooves 3 on the upstream pumping hydrophobic surface. Several imitation fin diversion protrusions 2 are juxtaposed between the smooth hydrophilic surface 1 and the helical groove 3 on the upstream pumping hydrophobic surface, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com