Vacuum baking-drying production line for lithium battery pole piece roll

A production line, lithium battery technology, applied in drying, drying machine, drying solid materials, etc., can solve the problems of inability to meet the production of large factories, secondary pollution of pole piece rolls, limited number of pole piece rolls, etc. The effect of baking reliability, avoiding contamination, and increasing the level of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

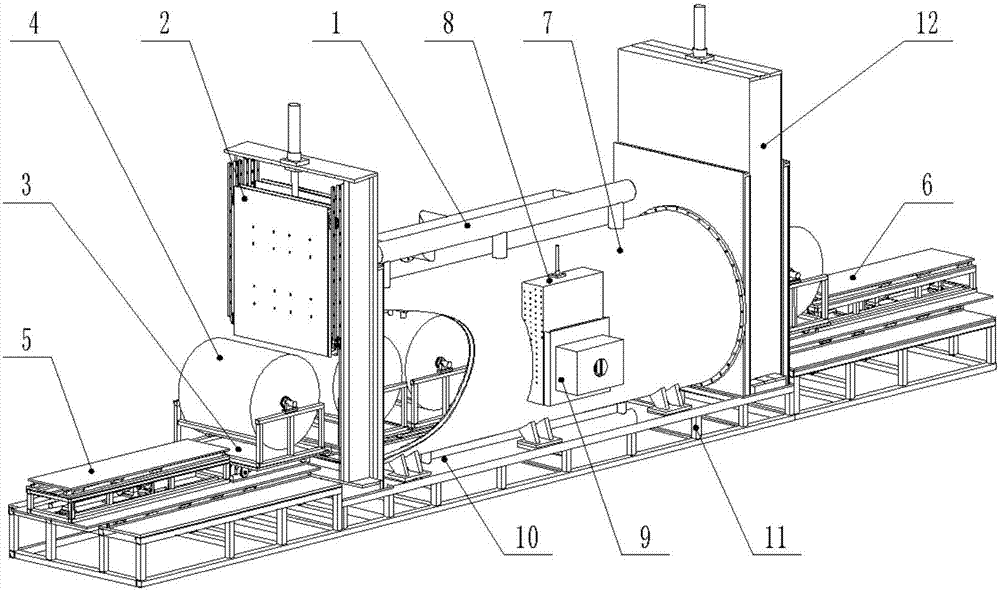

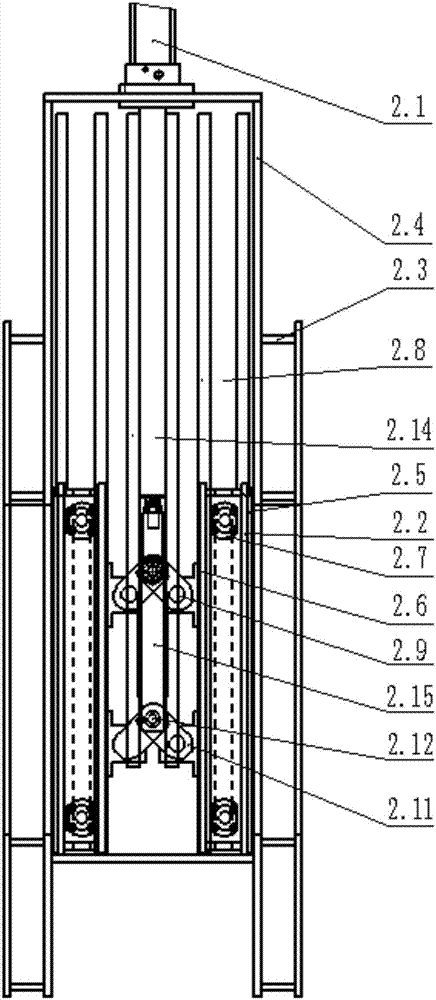

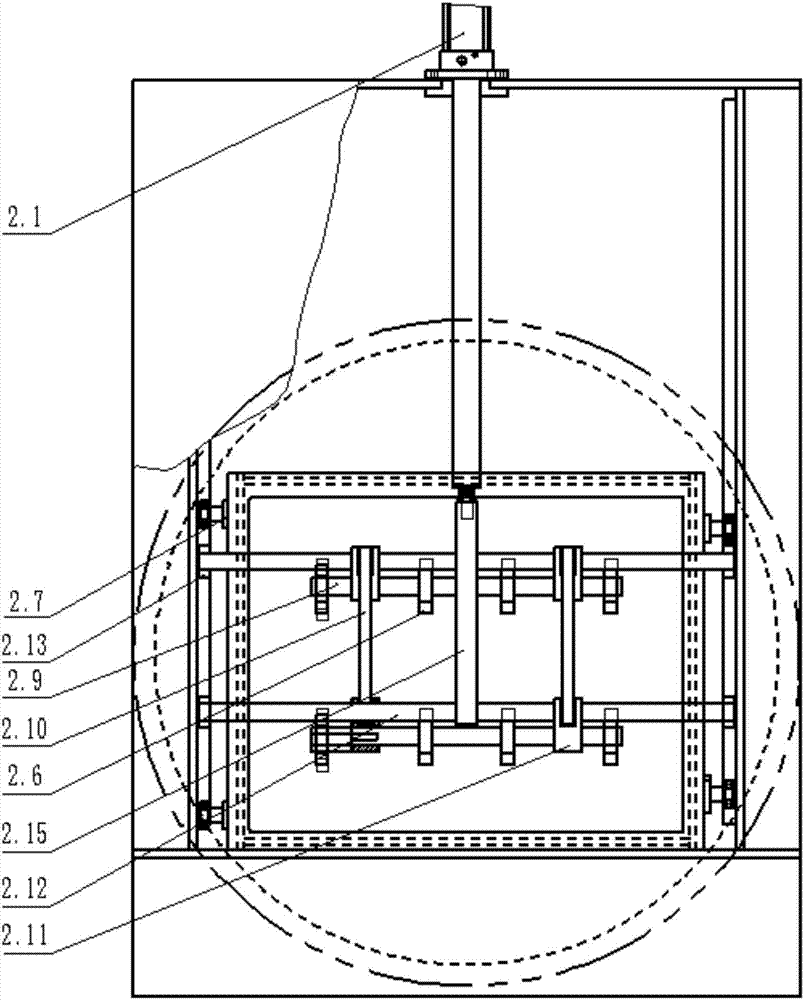

[0028] The invention provides a lithium battery pole piece roll vacuum baking and drying production line (referred to as the production line, see Figure 1-8 ), characterized in that the production line includes a nitrogen gas circulation pipeline 1, front doors and windows 2, at least two sets of pole piece roll trolleys 3, pole piece roll conveying device 5, pole piece roll dragging device 6, baking tank body 7, side doors and windows 8 , inspection port 9, vacuum pipeline 10, frame body 11 and rear door and window 12; The structure of the front door and window 2 is the same as that of the rear door and window 12;

[0029] One end of the nitrogen circulation pipe 1 extends into the inner lining body 7.1 of the baking tank body 7, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com