Colored film substrate and display device

A technology of color film substrate and reference, applied in nonlinear optics, instruments, optics, etc., can solve the problem that color film substrate cannot reduce ODFTactTime, etc., achieve the effect of reducing gas escape, optimizing surface flatness, and improving surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

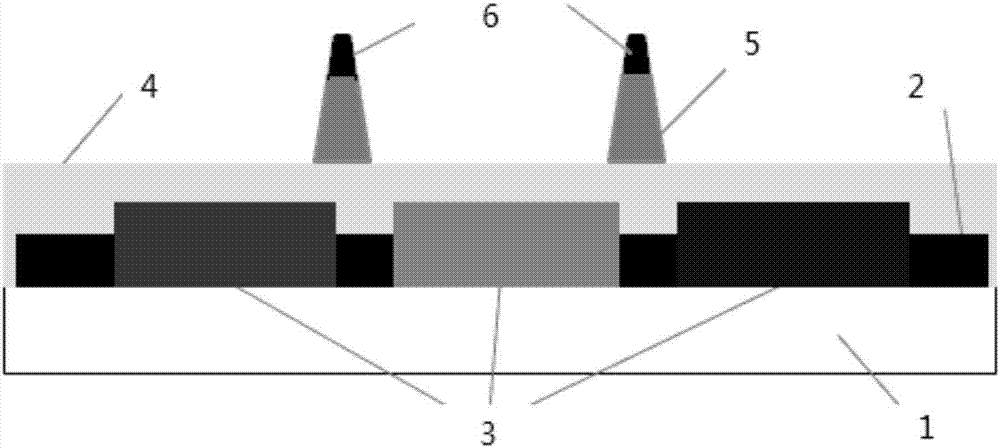

[0024] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

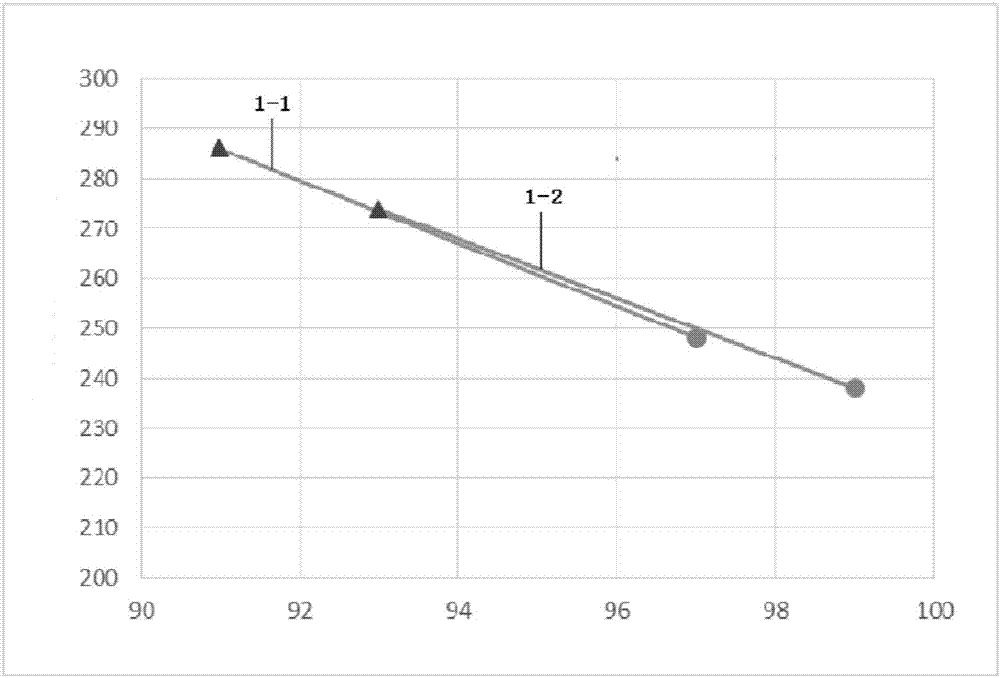

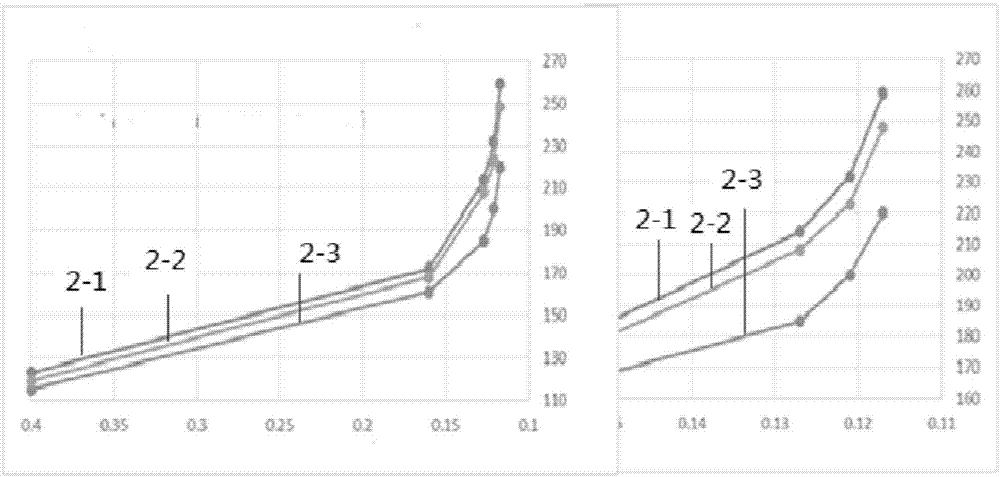

[0025] The existing CELL ODF process is the bottleneck process of the factory's capacity. In order to meet the production capacity requirements of a certain production line of a certain factory, it is necessary to reduce the ODF Tact Time (production takt) of the ADS products of this production line to increase the production capacity of the factory's products. By comparing the effects of the materials of the OC layer on the ODF Tact Time, the inventors found that the materials of the OC layer can affect the amount of gas released from the protective layer, thereby affecting the ODF Tact Time. Specifically, see Table 1 below.

[0026] Table 1: Vas Tact Time Comparison of TN&ADS Products

[0027]

[0028] By comparing the ODF T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com