A Design Method of Blank Shape for Die Forging Diesel Engine Crankshaft

A design method and diesel engine technology, applied in the field of forging, can solve problems such as excessive material consumption, difficulty in filling crankshaft forgings with special-shaped structures, high width, etc., and achieve the effects of reducing flash, shortening design cycle, and enhancing capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

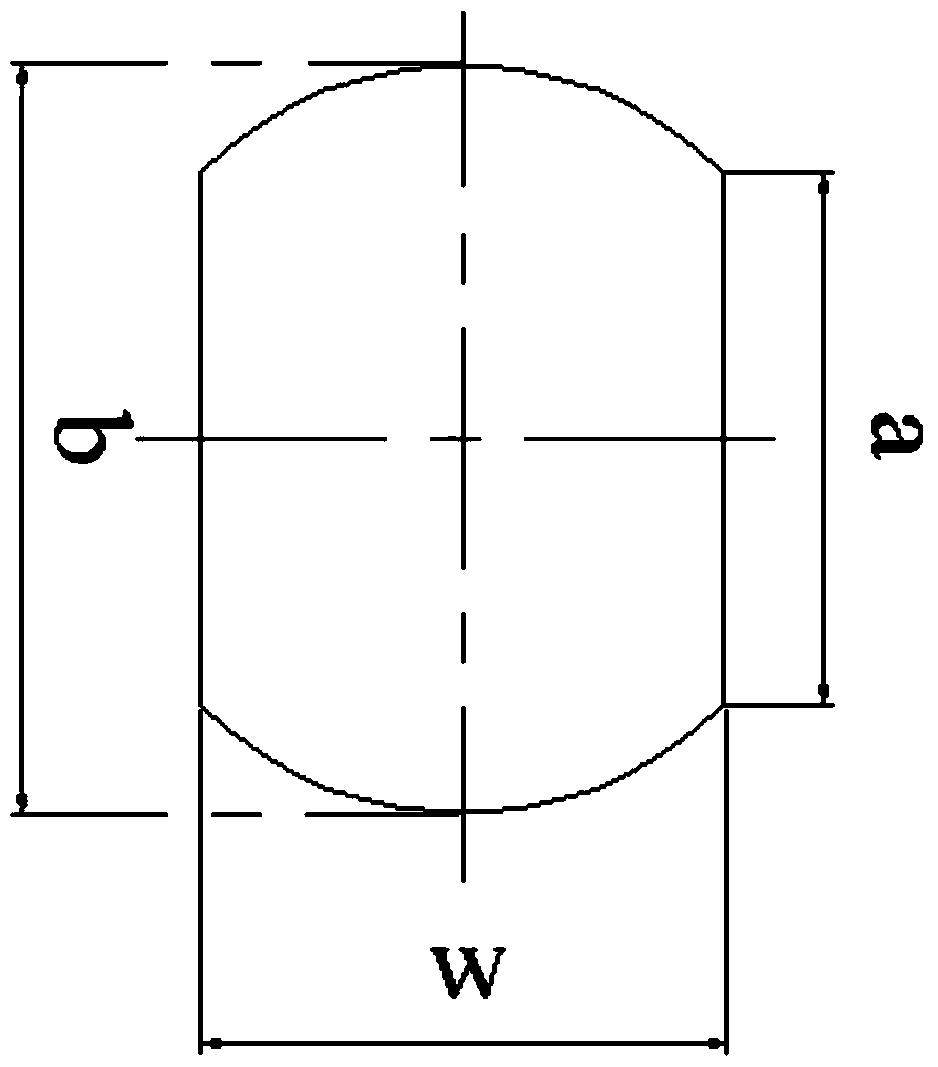

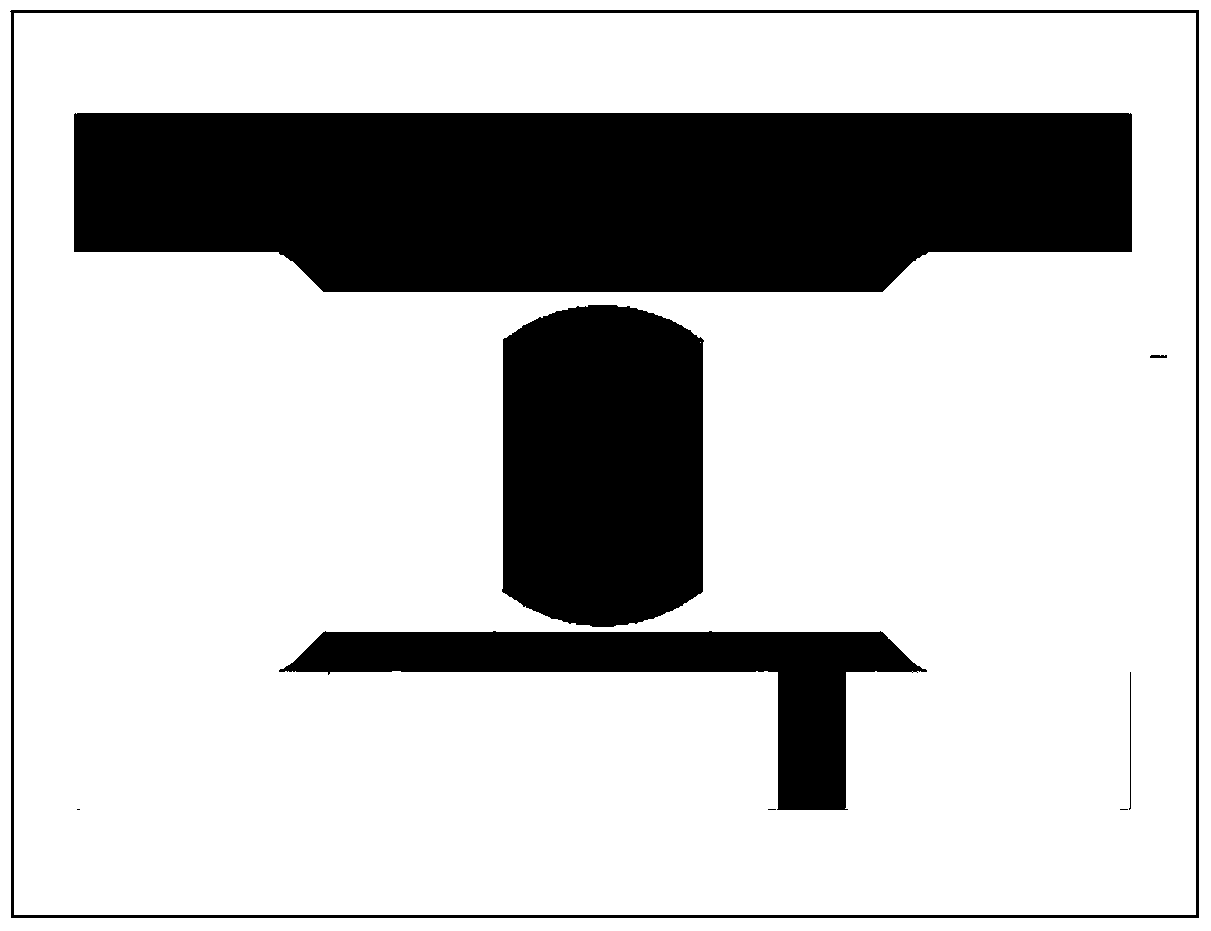

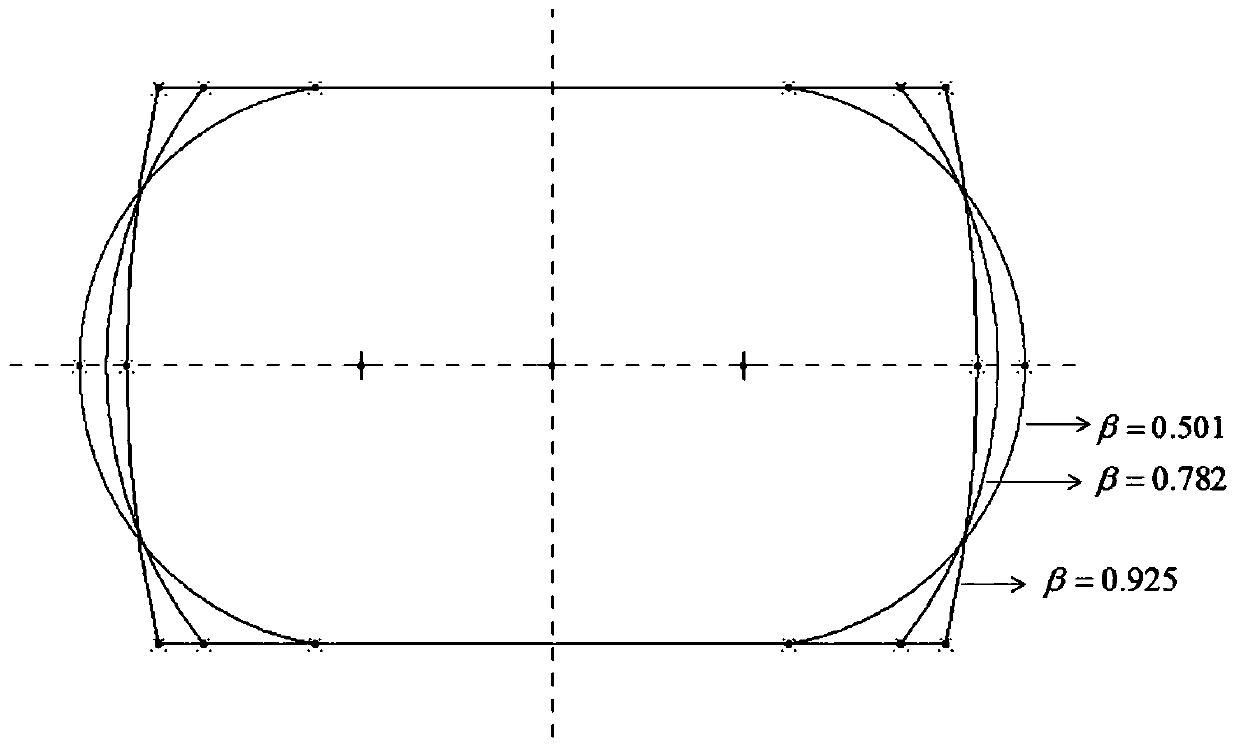

[0033] This embodiment is applied to the die forging production site of a certain type of plane split four-cylinder diesel engine crankshaft in a certain factory. The material of the billet is 42CrMo steel, and the forging weighs 22.3kg. The billet adopts a two-way arc-shaped cross section. It is heated to 1200°C before die forging. The die forging is carried out on a 6300-ton press. After pre-forging and final forging, the forging completely fills the cavity, the forming condition is good, and the maximum forming load decreases. The arc height ratio is 0.782, the width is 72mm, and the material utilization rate is increased by 8.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com