LED driving circuit

A technology of LED driving and switching driving circuits, which is applied in the field of circuits to achieve the effects of improving PFC, improving compatibility, and improving dimming characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

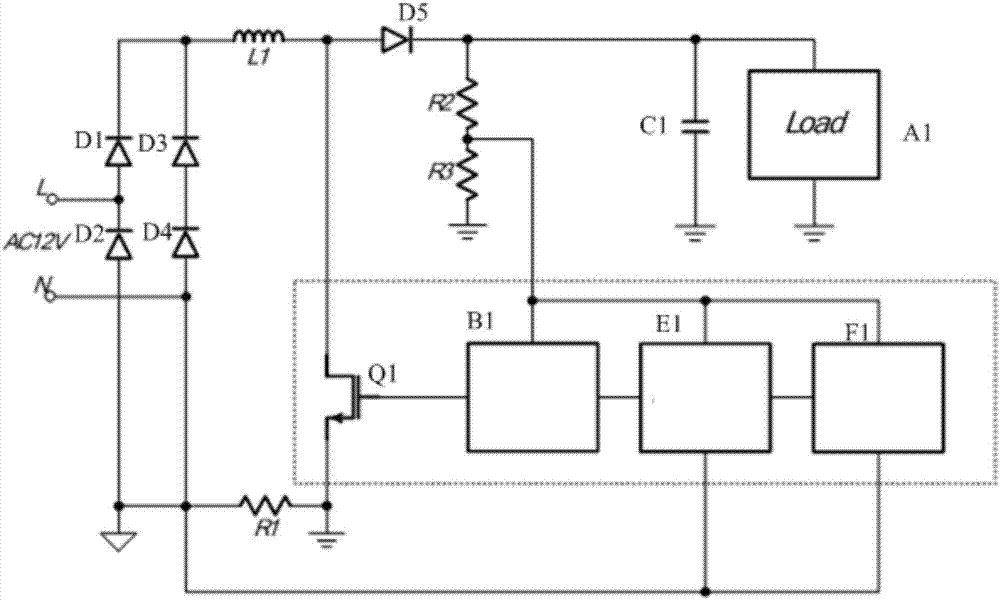

[0011] Such as figure 1 As shown, the LED driving circuit of the present invention includes a load A1, a switch driving circuit B1, an electronic transformer compatible circuit E1, a power factor correction circuit F1, a 12V AC power supply, a first inductor L1, a first capacitor C1, a first triode Q1, The first resistor R1, the second resistor R2, the third resistor R3, the first diode D1, the second diode D2, the third diode D3, the fourth diode D4, the fifth diode D5, The load A1 is connected in parallel with the first capacitor C1, the first inductor L1, the fifth diode D5, the second resistor R2 and the third resistor R3 are connected in series, the first diode D1 is connected with the third diode D3, and the fourth diode The tube D4 is connected in parallel, the first diode D1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com