Bidirectional spiral flow channel water cooling device

A two-way spiral, water-cooled heat dissipation technology, applied in cooling/ventilation/heating transformation, modification by conduction heat transfer, etc. Reasonable and other issues, to achieve the effect of easy installation, disassembly and maintenance, suitable for lightweight, fast and uniform heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

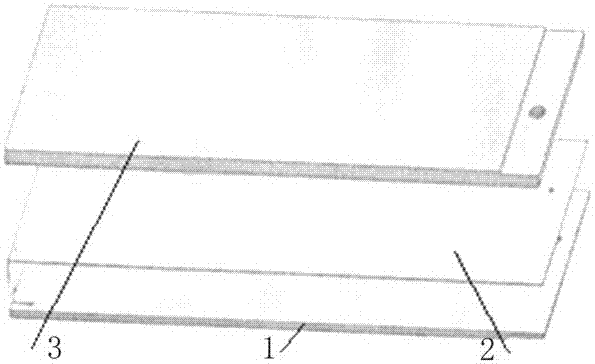

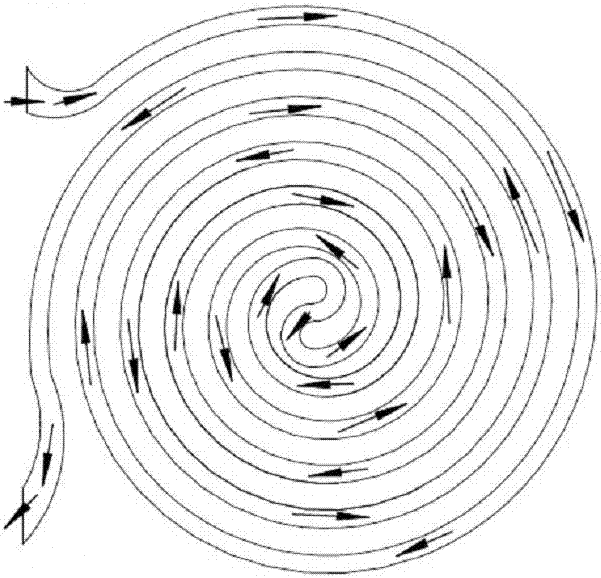

[0011] The two-way spiral flow channel water-cooling heat dissipation device is composed of three layers of cooling main board 1, brazing plate 2, and cover plate 3; the cooling main board 1 is provided with a bidirectional spiral flow channel that is centrally symmetrical and smoothly connected through the center of symmetry. The cover plate 3 is provided with two water joints perpendicular to the cover plate surface, and the water joints are respectively connected with the two ends of the flow channel; the cover plate 3 and the cooling main board 1 are provided with a plurality of mounting threaded holes.

[0012] During specific implementation, the water connector is arranged on the side edge of the water-cooled main board 1 and arranged parallel to the water-cooled main board 1 .

[0013] During specific installation and use, according to the installation requirements of the external interface, the docking position of the water connector and the flow channel should be reaso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com