Multi-function stratification instrument for ultra-high speed centrifugal liquid and centrifugal liquid stratification method

An ultra-high-speed centrifugal and multi-functional technology, applied in centrifuges and other directions, can solve the problems of ultra-high-speed centrifuged liquid stratification difficulties, etc., and achieve the effects of easy popularization, low manufacturing cost, and wide application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

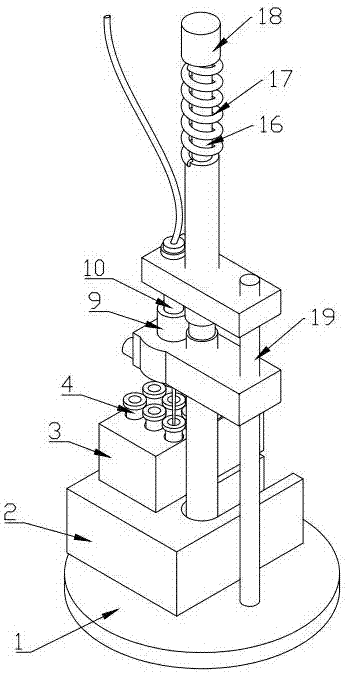

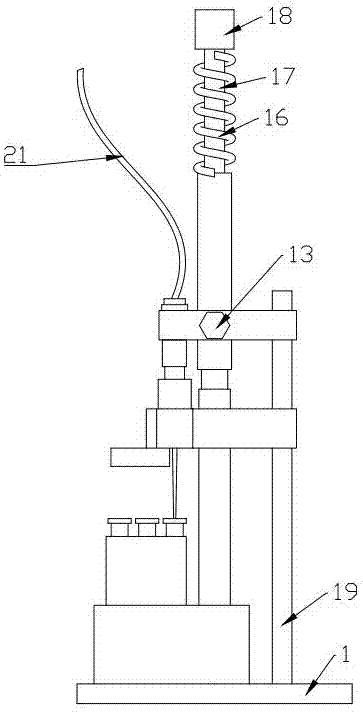

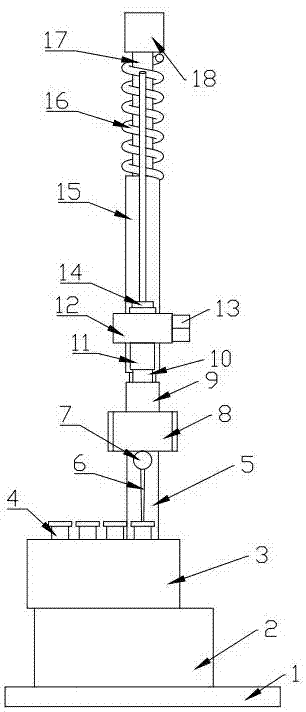

[0029] Embodiment 1: A kind of multifunctional stratification instrument for ultrahigh-speed centrifugal liquid, see Figure 1 to Figure 5 , including a platform 1 provided with a platform support tube 5, a liquid inlet mechanism, a centrifuge tube fixing mechanism, and a layered liquid taking mechanism that are set on the platform 1 from top to bottom along the platform support tube 5; the liquid inlet mechanism includes Jacking bracket 12, the jacking bracket 12 is provided with a through hole forming a moving pair with the stand support tube 5, an adjusting nut 13 for fixing the position of the jacking bracket 12, and an oil drop hole through which the oil can pass. Pipe 21, the end seal 14 is provided between the oil drop hole and the liquid inlet pipe 21; the centrifuge tube fixing mechanism includes a bottom bracket 8 fixed on the stand support tube 5, and the bottom bracket 8 is provided with a through hole for clamping the centrifuge tube The layered liquid taking mech...

Embodiment 2

[0039] Embodiment 2: The principle of this embodiment is the same as that of Embodiment 1. The specific difference is that the layered liquid taking mechanism is replaced by a hinged connection with a detachable buckle, which saves the cost of parts processing.

Embodiment 3

[0040] Embodiment 3: The principle of this embodiment is the same as that of Embodiment 1. The specific difference is that the layered liquid taking mechanism is replaced by a hinged connection with a detachable buckle, which saves the cost of parts processing. The specific fastening is accomplished through buckles and slots provided at corresponding positions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com