Special-shaped composite material shaft, preparation method thereof, and connecting method of special-shaped composite material shaft and metal couplings

A composite material and special-shaped technology, which is applied in the field of its preparation and special-shaped composite material shaft, can solve the problems of destroying fiber continuity, affecting product performance, and weak torsion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] In the preparation method according to the present disclosure, the prepreg tape (or prepreg) is conventional in the art, and may contain reinforcing fibers and thermosetting resins, which means impregnating continuous fibers or fabrics with a resin matrix under strictly controlled conditions ( Especially tape-shaped reinforced fiber fabric), made of resin matrix and reinforcement composition. Wherein, the type of reinforcing fiber has no special requirements, and it can be the type of reinforcing fiber commonly used in the field of composite materials. For example, the reinforcing fiber can be selected from carbon fiber, ultra-high molecular weight polyethylene fiber, aramid fiber, basalt fiber and glass fiber. one or several. The aforementioned types of reinforcing fibers have high strength, good weavability, and good compatibility with thermosetting resins.

[0037] In the method according to the present disclosure, the thermosetting resin can be a thermosetting resi...

Embodiment 1

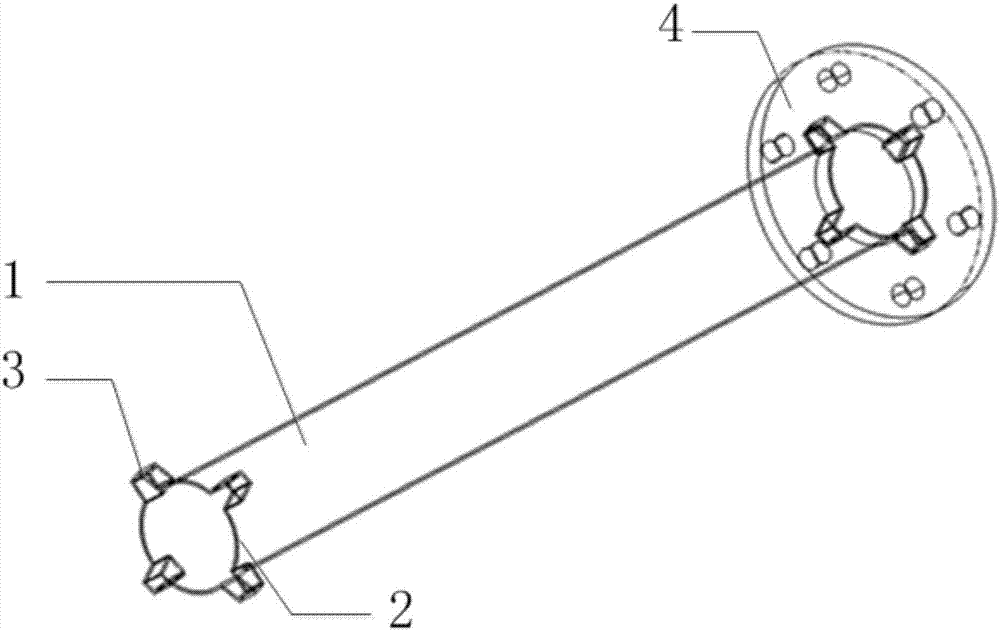

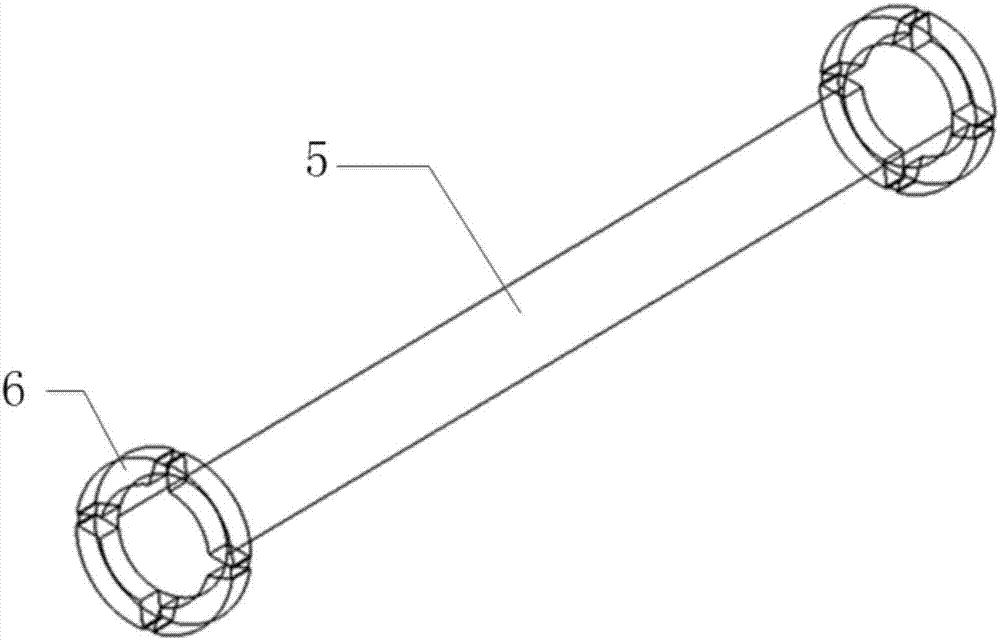

[0044] This embodiment is used to illustrate the preparation method of the special-shaped composite material shaft and the connection method between the metal flange and the composite material shaft of the present disclosure. The shape of the special-shaped composite material shaft is as follows figure 1 As shown, it includes a hollow shaft body section 1 and end connection sections 2 at both ends, the number of fixing protrusions 3 on each end connection section 2 is four, and the first inflatable mandrel 5 and the second inflatable mandrel 6 The shape of the assembled mandrel body is as follows figure 2 shown.

[0045] Respectively process the first inflatable mandrel 5 and eight second inflatable mandrels 6 of the illustrated shape and assemble them into figure 2 As shown in the mandrel body, a prepreg tape (purchased from SGL, brand name SIGRAFIL CT50-4.0 / 240-E100) was wound on the surface of the mandrel body, and 4 layers were wound to obtain a preform.

[0046] Put t...

Embodiment 2

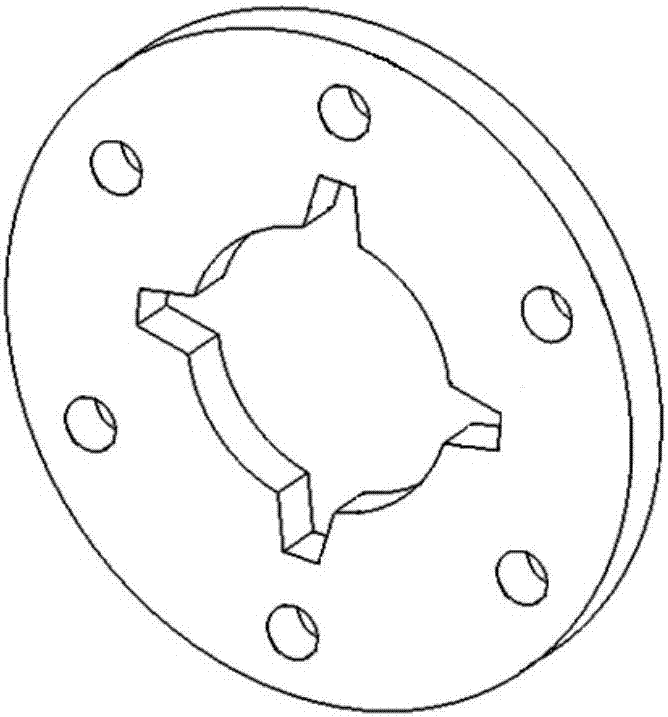

[0050] This example is used to illustrate the preparation method of the special-shaped composite material shaft and the connection method between the metal flange and the composite material shaft of the present disclosure. The number of protrusions is 6, and the special-shaped composite material shaft of this embodiment is obtained.

[0051] The end connecting portion of the special-shaped composite material shaft was inserted into the metal flange matching the connecting hole, and the maximum torque of the connecting structure was measured to be 643N·m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum torque | aaaaa | aaaaa |

| Maximum torque | aaaaa | aaaaa |

| Maximum torque | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com