Air-levitated train

A technology of air flotation and trains, which is applied in the field of rail transit, can solve pollution and other problems, and achieve the effects of low pollution, good stability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

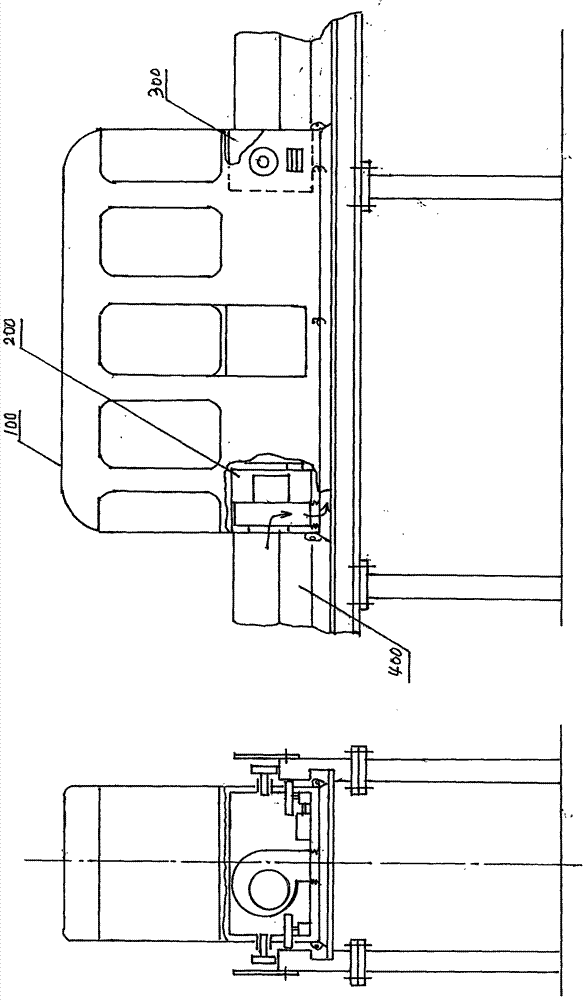

[0037] figure 1 The overall structure diagram of the embodiment of the air bearing train of the present invention is given.

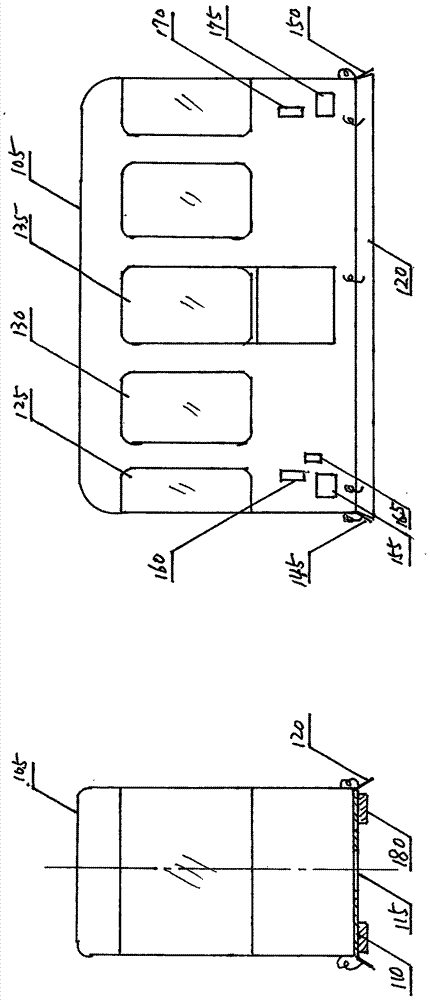

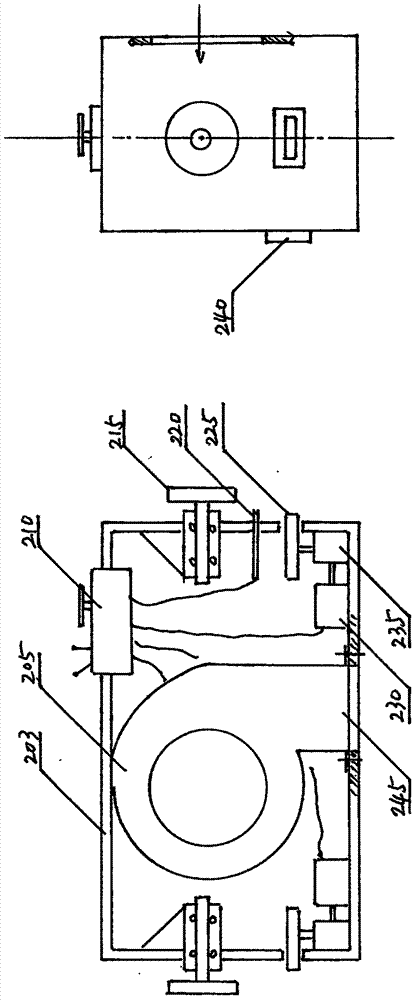

[0038] The overall structure of the embodiment of the air-floating train provided by the present invention is composed of multiple sections, and each section includes: an air-floating car 100 , a front power box 200 , a rear power box 300 , and a track device 400 .

[0039] The air-floating carriage 100 is composed of a car body, a windshield, a vehicle window, a car door, a front tugboat opening, a front driving wheel opening, a pantograph opening, a front windshield, a side windshield, a rear windshield, a rear tugboat mouth and a rear drive wheel mouth composition.

[0040] The air flotation car 100 relies on the blower to provide high-pressure air, squeezes it into the bottom of the car, and forms an air cushion i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com