A method for acid oxidation modification of sintering flue gas semi-dry desulfurization ash

A semi-dry desulfurization and oxidation modification technology, applied in the direction of calcium/strontium/barium sulfate, etc., can solve the problems of poor oxidation efficiency and speed up the oxidation efficiency of desulfurization ash, so as to reduce reaction energy consumption, speed up oxidation efficiency, and improve The effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

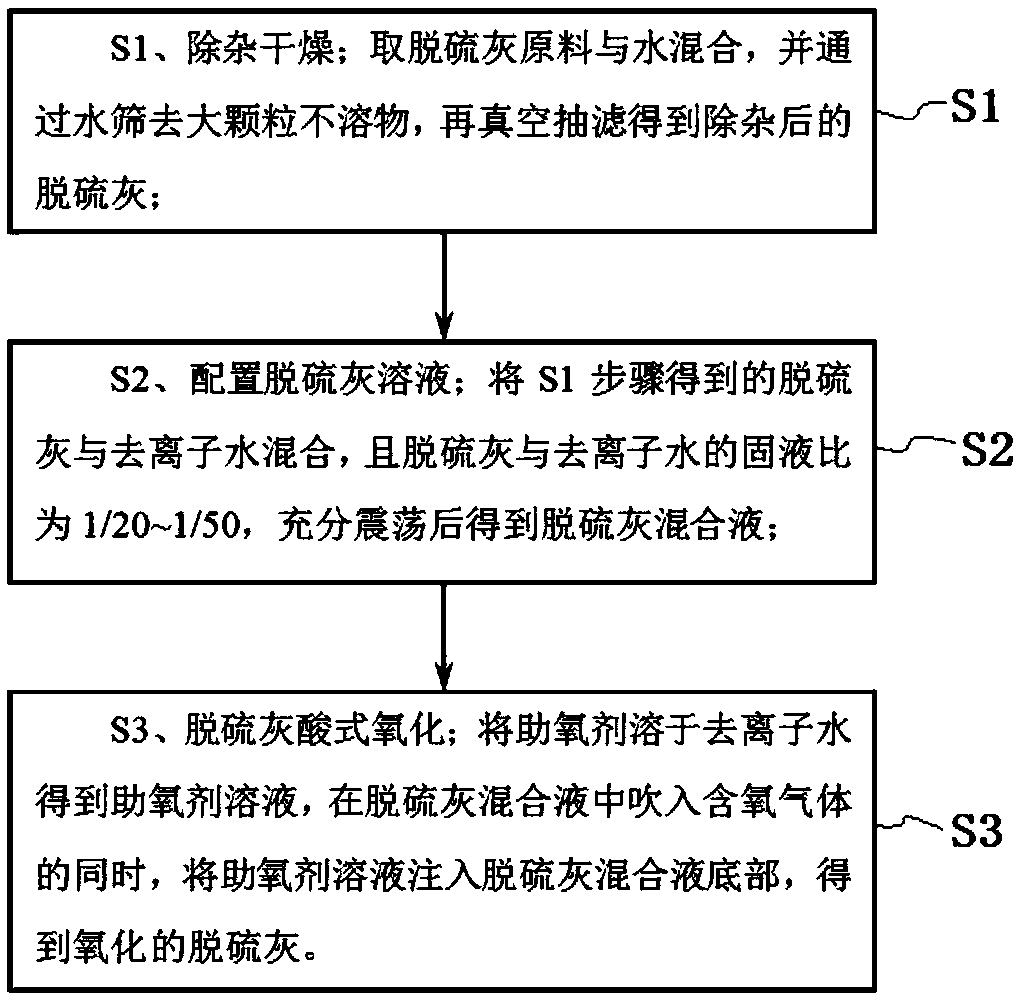

Image

Examples

Embodiment 1

[0039] A method for acidic oxidation modification of sintered flue gas semi-dry desulfurization ash according to the present invention, wherein the oxygen promoter used includes an acidic promoter, and the acidity of the acidic promoter is between sulfurous acid and sulfuric acid, that is, acidic Auxiliary pKa 1 The acidity coefficient is between the pKa of sulfurous acid and sulfuric acid 1 Between the acidity coefficients, the oxygen promoter is used to oxidize the calcium sulfite in the desulfurization ash, the acid promoter is easily soluble in water, and the pKa of the acid promoter in 25°C water 1 The acidity coefficient is: 1.00-1.89, where the pKa 1 Is the first-order acidity coefficient of the acidic auxiliary agent, and the acidic auxiliary agent of the present embodiment is oxalic acid, and its pKa 1 is 1.27; the oxygen promoter in the present embodiment is oxalic acid, and the oxygen promoter solution is obtained after mixing oxalic acid with water. Among them: ...

Embodiment 2

[0052] The basic content of this embodiment is the same as that of Example 1, except that the acidic additive is dichloroacetic acid (CHCl 2 COOH), its pKa in water at 25°C 1 is 1.30, the oxygen promoter in this embodiment is dichloroacetic acid, and the oxygen promoter solution is obtained after dichloroacetic acid is mixed with water. The oxygen promoter of the invention greatly improves the oxidation efficiency of the desulfurization ash, and realizes the oxidation of the desulfurization ash under the condition of low temperature in an open container. After the reaction, the reactant precipitate is oxidatively modified desulfurization ash, which is heated and dried at a temperature of 100° C. to obtain a dry powder. The content of calcium sulfate dihydrate in the dry powder reaches 95.3%.

Embodiment 3

[0054] The basic content of this embodiment is the same as that of Example 1, except that the acidic auxiliary agent is composed of oxalic acid and dichloroacetic acid, and the mass ratio of oxalic acid and dichloroacetic acid is 2:1. The agent consists of oxalic acid and dichloroacetic acid. The use of the oxygen promoter of the present invention greatly improves the oxidation efficiency of desulfurization ash, and realizes the oxidation of desulfurization ash under the low temperature condition of an open container. It is heated and dried at a temperature of 100° C. to obtain a dry powder, and the content of calcium sulfate dihydrate in the dry powder reaches 94.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com