Method for constructing upper conduit frame of six-pile conduit frame

A construction method and jacket technology, applied in construction, manufacturing tools, infrastructure engineering, etc., can solve the problems of low manufacturing precision, large manpower, material and financial resources, and huge jacket volume, and achieve the effect of easy assembly and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

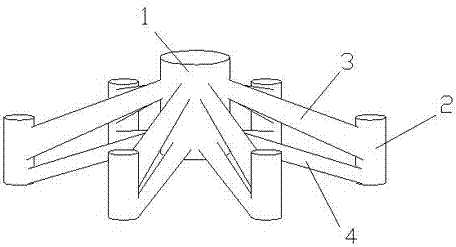

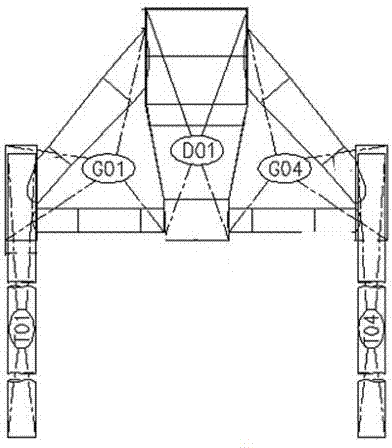

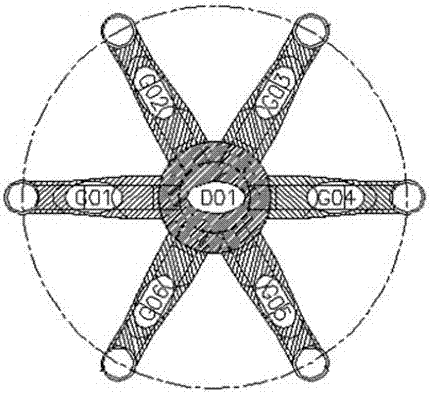

[0044] Such as figure 1 A six-pile jacket shown includes a main cylinder 1, a support tube and a pile sleeve 2. The main cylinder 1 is vertically arranged at the center of the jacket and connected to the pile sleeve 2 through a support tube. The support tube There are six groups evenly surrounding and installed on the side of the main cylinder 1, each group is connected to a pile casing 2, and each group of support pipes includes a diagonal brace 3 and a horizontal brace 4; the pile casing 2 is a hollow tube, and the same The shaft sleeve is arranged on the upper end of each pile casing 2, forming an annular space with the pile casing 2, and high-strength grouting material is poured in the annular space; the upper jacket includes the main cylinder 1 and the support pipe, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com