Silicone composition for printing plates, lithographic printing plate master, lithographic printing plate and method of producing printed matter

A technology of silicone composition and lithographic printing plate, applied in lithographic printing equipment, printing, printing plates, etc., can solve the problems of ink repellency decline, etc., and achieve the effect of excellent adhesion and excellent damage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

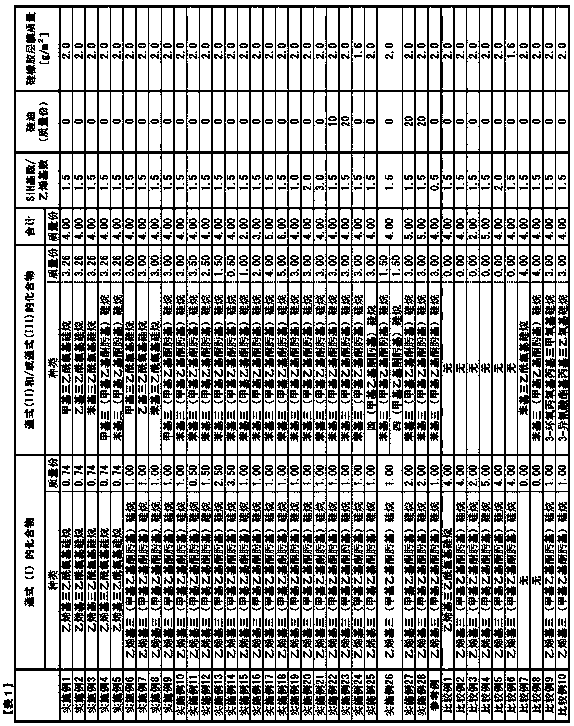

Embodiment 1

[0246] On a degreased aluminum substrate (manufactured by Mitsubishi Almi Co., Ltd.) with a thickness of 0.24mm, apply the following dilution of the heat-insulating layer composition, and dry it at 200°C for 90 seconds, and set the film mass to 10g / m 2 insulation layer.

[0247]

[0248] Put the following component (a) into the container, while stirring with THREE-ONE MOTOR (スリーワンmotor), slowly add the components (b), (c), (d), and (e) in order, and stir and mix until the components become even. Components (f) and (g) were added to the obtained mixed liquid, and stirred and mixed for 10 minutes, thereby obtaining a heat insulating layer composition diluted liquid.

[0249] (a) Titanium oxide dispersion liquid: "タイペーク" (registered trademark) CR-50 (manufactured by Ishihara Sangyo Co., Ltd.) N,N-dimethylformamide dispersion liquid (titanium oxide 50% by mass): 60 parts by mass

[0250] (b) Epoxy resin: "JER" (registered trademark) 1010 (manufactured by Mitsubishi Chemical Co...

Embodiment 2

[0279] A lithographic printing plate precursor was prepared in the same manner as in Example 1, except that the diluted silicone composition for printing plates-1 was changed to the following diluted silicone composition for printing plates-2. , plate making, evaluation.

[0280]

[0281] (a) "アイソパー" (registered trademark) E: 894.05 parts by mass

[0282] (b) "DMS"-V35: 93.39 parts by mass

[0283] (c) "HMS"-301: 2.56 parts by mass

[0284] (d) Vinyltriacetoxysilane: 0.74 parts by mass

[0285] (e) Compound represented by general formula (II): ethyltriacetoxysilane: 3.26 parts by mass

[0286] (f) γ-picoline: 1.00 parts by mass

[0287] (g) XC94-C4326: 5.00 parts by mass

[0288] The ratio of the number of SiH groups to the number of vinyl groups (number of SiH groups / number of vinyl groups) of the silicone rubber layer was 1.5.

Embodiment 3

[0290] A lithographic printing plate precursor was prepared in the same manner as in Example 1 except that the diluted silicone composition for printing plates-1 was changed to the following diluted silicone composition for printing plates-3. , plate making, evaluation.

[0291]

[0292] (a) "アイソパー" (registered trademark) E: 894.05 parts by mass

[0293] (b) "DMS"-V35: 93.39 parts by mass

[0294] (c) "HMS"-301: 2.56 parts by mass

[0295] (d) Vinyltriacetoxysilane: 0.74 parts by mass

[0296] (e) Compound represented by general formula (II): phenyltriacetoxysilane: 3.26 parts by mass

[0297] (f) γ-picoline: 1.00 parts by mass

[0298] (g) XC94-C4326: 5.00 parts by mass

[0299] The ratio of the number of SiH groups to the number of vinyl groups (number of SiH groups / number of vinyl groups) of the silicone rubber layer was 1.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com